Кондиционеры Tesla TT68X71 - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

62

ENG

supply to equipment during servicing, then a permanently operating form of leak detection shall be located at

the most critical point to warn of a potentially hazardous situation.

2. Particular attention shall be paid to the following to ensure that by working on electrical components, the

casing is not altered in such a way that the level of protection is affected. This shall include damage to cables,

excessive number of connections, terminals not made to original specification, damage to seals, incorrect

fitting of glands, etc.

Ensure that apparatus is mounted securely.

Ensure that seals or sealing materials have not degraded such that they no longer serve the purpose of

preventing the ingress of flammable atmospheres. Replacement parts shall be in accordance with the

manufacturer’s specifications.

NOTE: The use of silicon sealant may inhibit the effectiveness of some types of leak detection equipment.

Intrinsically safe components do not have to be isolated prior to working on them.

18.

Repair to intrinsically safe components

Do not apply any permanent inductive or capacitance loads to the circuit without ensuring that this will not

exceed the permissible voltage and current permitted for the equipment in use.

Intrinsically safe components are the only types that can be worked on while live in the presence of a

flammable atmosphere. The test apparatus shall be at the correct rating.

Replace components only with parts specified by the manufacturer. Other parts may result in the ignition of

refrigerant in the atmosphere from a leak.

19.

Cabling

Check that cabling will not be subject to wear, corrosion, excessive pressure, vibration, sharp edges or any

other adverse environmental effects. The check shall also take into account the effects of aging or continual

vibration from sources such as compressors or fans.

20.

Detection of flammable refrigerants

Under no circumstances shall potential sources of ignition be used in the searching for or detection of

refrigerant leaks. Ahalide torch (or any other detector using a naked flame) shall not be used.

21.

Leak detection methods

The following leak detection methods are deemed acceptable for systems containing flammable refrigerants.

Electronic leak detectors shall be used to detect flammable refrigerants, but the sensitivity may not be

adequate, or may need re-calibration. (Detection equipment shall be calibrated in a refrigerant-free area.)

Ensure that the detector is not a potential source of ignition and is suitable for the refrigerant used. Leak

detection equipment shall be set at a percentage of the LFL of the refrigerant and shall be calibrated to the

refrigerant employed and the appropriate percentage of gas (25 % maximum) is confirmed.

Leak detection fluids are suitable for use with most refrigerants but the use of detergents containing chlorine

shall be avoided as the chlorine may react with the refrigerant and corrode the copper pipe-work.

If a leak is suspected, all naked flames shall be removed/ extinguished.

If a leakage of refrigerant is found which requires brazing, all of the refrigerant shall be recovered from the

system, or isolated (by means of shut off valves) in a part of the system remote from the leak. Oxygen free

nitrogen (OFN) shall then be purged through the system both before and during the brazing process.

22.

Removal and evacuation

When breaking into the refrigerant circuit to make repairs or for any other purpose conventional procedures

shall be used. However, it is important that best practice is followed since flammability is a consideration. The

following procedure shall be adhered to:

- Remove refrigerant;

- Purge the circuit with inert gas;

- Evacuate;

- Purge again with inert gas;

-Open the circuit by cutting or brazing.

The refrigerant charge shall be recovered into the correct recovery cylinders. The system shall be flushed

with OFN to render the unit safe. This process may need to be repeated several times. Compressed air or

oxygen shall not be used for this task.

Flushing shall be achieved by breaking the vacuum in the system with OFN and continuing to fill until the

working pressure is achieved, then venting to atmosphere, and finally pulling down to a vacuum. This process

shall be repeated until no refrigerant is within the system. When the final OFN charge is used, the system shall

be vented down to atmospheric pressure to enable work to take place. This operation is absolutely vital if

brazing operations on the pipe-work are to take place.

Ensure that the outlet for the vacuum pump is not close to any ignition sources and there is ventilation

available.

23.

Decommissioning

Before carrying out this procedure, it is essential that the technician is completely familiar with the equipment

Содержание

- 2 RUS

- 4 ПРАВИЛА БЕЗОПАСНОСТИ

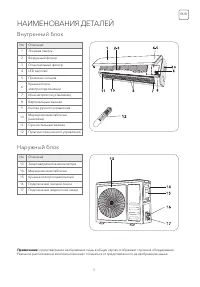

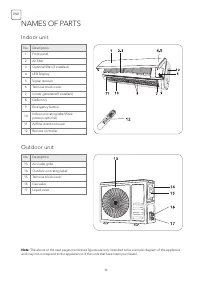

- 5 НАИМЕНОВАНИЯ ДЕТАЛЕЙ; Внутренний блок

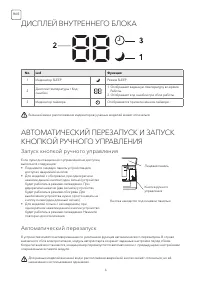

- 6 ДИСПЛЕЙ ВНУТРЕННЕГО БЛОКА; Запуск кнопкой ручного управления

- 7 ПУЛЬТ ДИСТАНЦИОННОГО УПРАВЛЕНИЯ

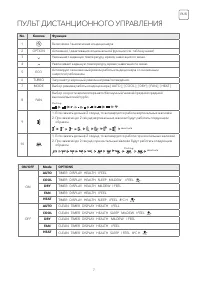

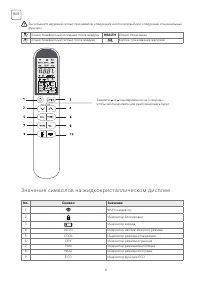

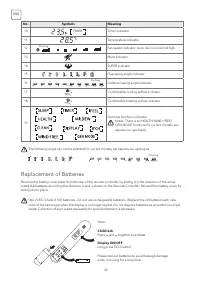

- 8 Значения символов на жидкокристаллическом дисплее

- 9 Замена батареек

- 10 ИНСТРУКЦИЯ ПО ЭКСПЛУАТАЦИИ; Контроль воздушного потока

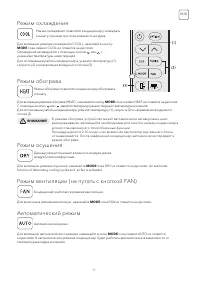

- 11 Режим охлаждения

- 12 Функция ECO

- 13 Режим самостоятельной очистки

- 14 Функция I FEEL

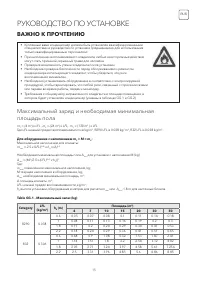

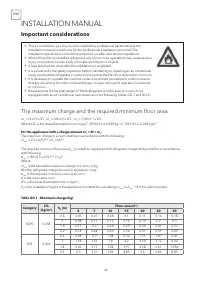

- 15 РУКОВОДСТВО ПО УСТАНОВКЕ; ВАЖНО К ПРОЧТЕНИЮ

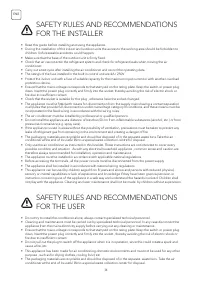

- 16 Правила безопасности при установке

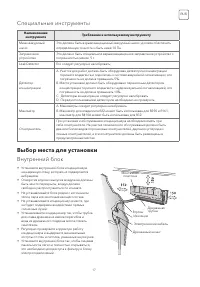

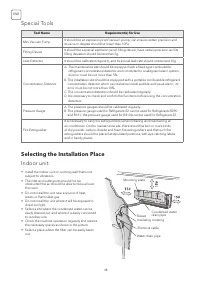

- 17 Специальные инструменты; Выбор места для установки

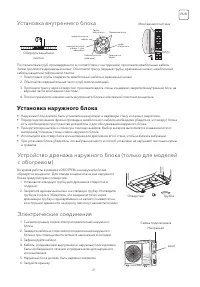

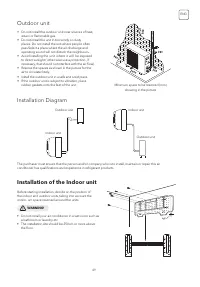

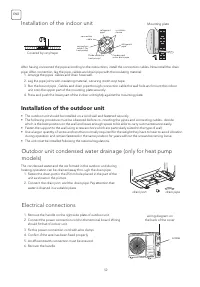

- 18 Наружный блок; Установка внутреннего блока

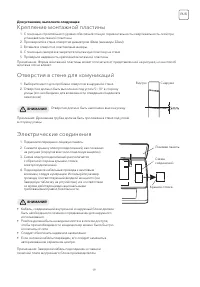

- 19 Крепление монтажной пластины

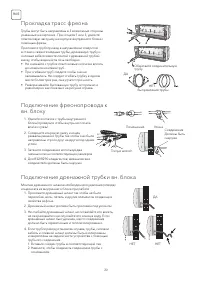

- 20 Прокладка трасс фреона

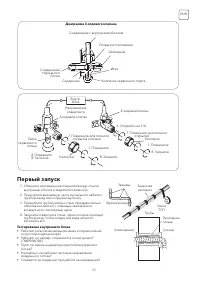

- 21 Электрические соединения; Установка наружного блока

- 22 Утечка

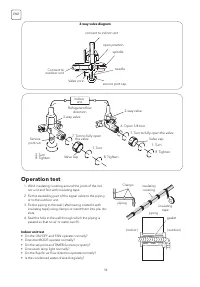

- 23 Первый запуск

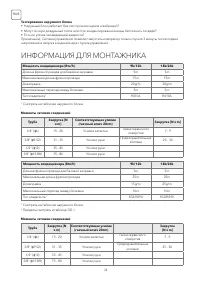

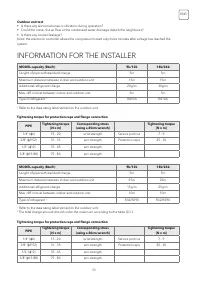

- 24 ИНФОРМАЦИЯ ДЛЯ МОНТАЖНИКА

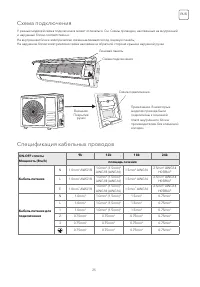

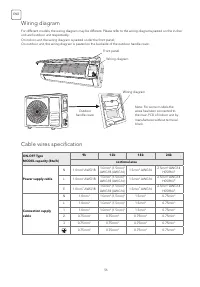

- 25 Схема подключения

- 27 ТЕХНИЧЕСКОЕ ОБСЛУЖИВАНИЕ

- 28 УСТРАНЕНИЕ НЕПОЛАДОК

- 29 ИНСТРУКЦИЯ ПО ОБСЛУЖИВАНИЮ

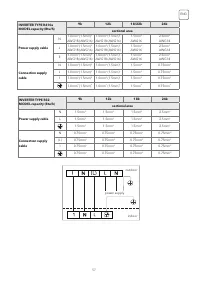

Характеристики

Остались вопросы?Не нашли свой ответ в руководстве или возникли другие проблемы? Задайте свой вопрос в форме ниже с подробным описанием вашей ситуации, чтобы другие люди и специалисты смогли дать на него ответ. Если вы знаете как решить проблему другого человека, пожалуйста, подскажите ему :)