Электрорубанки Bosch 0.601.5A0.300 - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

16

| English

1 609 92A 0KP | (13.5.14)

Bosch Power Tools

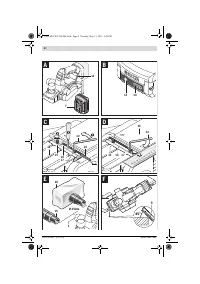

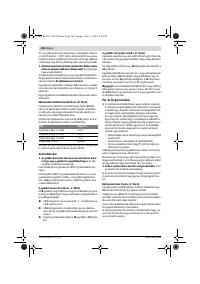

Do not reach into the saw dust ejector with your hands.

They could be injured by rotating parts.

To ensure optimum extraction of dust/chips, always work

with external dust extraction or a chip/dust bag.

External Dust Extraction (see figure E)

An extraction hose (Ø 35 mm)

19

(accessory), can be at-

tached on either side of the chip ejector.

Connect the vacuum hose

19

to a vacuum cleaner (accesso-

ry). An overview for connecting to various vacuum cleaners

can be found at the end of this manual.

The vacuum cleaner must be suitable for the material being

worked.

When vacuuming dry dust that is especially detrimental to

health or carcinogenic, use a special vacuum cleaner.

Integrated Dust Extraction (see figure E)

A chip/dust bag (accessory)

20

can be used for smaller jobs.

Insert the sleeve of the chip/dust bag firmly into the chip ejec-

tor

1

. Empty the chip/dust bag

20

at regulary intervals to

maintain optimum dust collection.

Choice of Chip Ejector Side

With the selector lever

4

, the chip ejector

1

can be switched

to right or left. Always press the selector lever

4

until it engag-

es in the end position. The selected ejection direction is indi-

cated by an arrow symbol on the selector lever

4

.

Operation

Operating Modes

Adjusting the Planing Depth

With the adjustment knob

2

, the planing depth can be adjust-

ed variably from 0 – 1.6 mm using the planing depth scale

3

.

Starting Operation

Inserting the battery

Insert the charged battery

7

into the battery port until it can

be felt to engage and is seated flush.

Switching On and Off

To

start

the machine,

first

push the lock-off button for the

On/Off switch

5

and

then

press the On/Off switch

6

and keep

it pressed.

To

switch off

the machine, release the On/Off switch

6

.

Note:

For safety reasons, the On/Off switch

6

cannot be

locked; it must remain pressed during the entire operation.

To save energy, only switch the power tool on when using it.

Run-on Brake

An integrated run-on brake reduces after-running of the blade

shaft after switching off the machine.

Protection Against Deep Discharging

The lithium-ion battery is protected against deep discharging

by the “Electronic Cell Protection (ECP)”. When the battery is

empty, the machine is switched off by means of a protective

circuit: The inserted tool no longer rotates.

Working Advice

Planing

Set the required planing depth and place the front part of the

planer base plate

10

against the workpiece.

Apply the machine to the workpiece only when

switched on.

Otherwise there is danger of kickback when

the cutting tool jams in the workpiece.

Switch the machine on and guide the machine with even feed

over the surface to be planed.

To achieve high-grade surfaces, work only with low feed and

apply pressure on the centre of the planer base plate.

When machining hard materials (e. g. hardwood) as well as

when utilising the maximum planer width, set only low planing

depths and reduce planer feed, as required.

Excessive feed reduces the surface quality and can lead to

rapid clogging of the chip ejector.

Only sharp blades achieve good cutting capacity and give the

machine longer life.

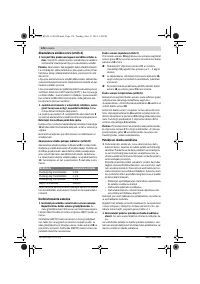

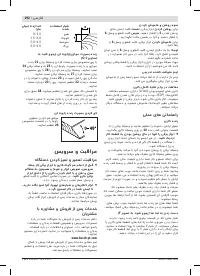

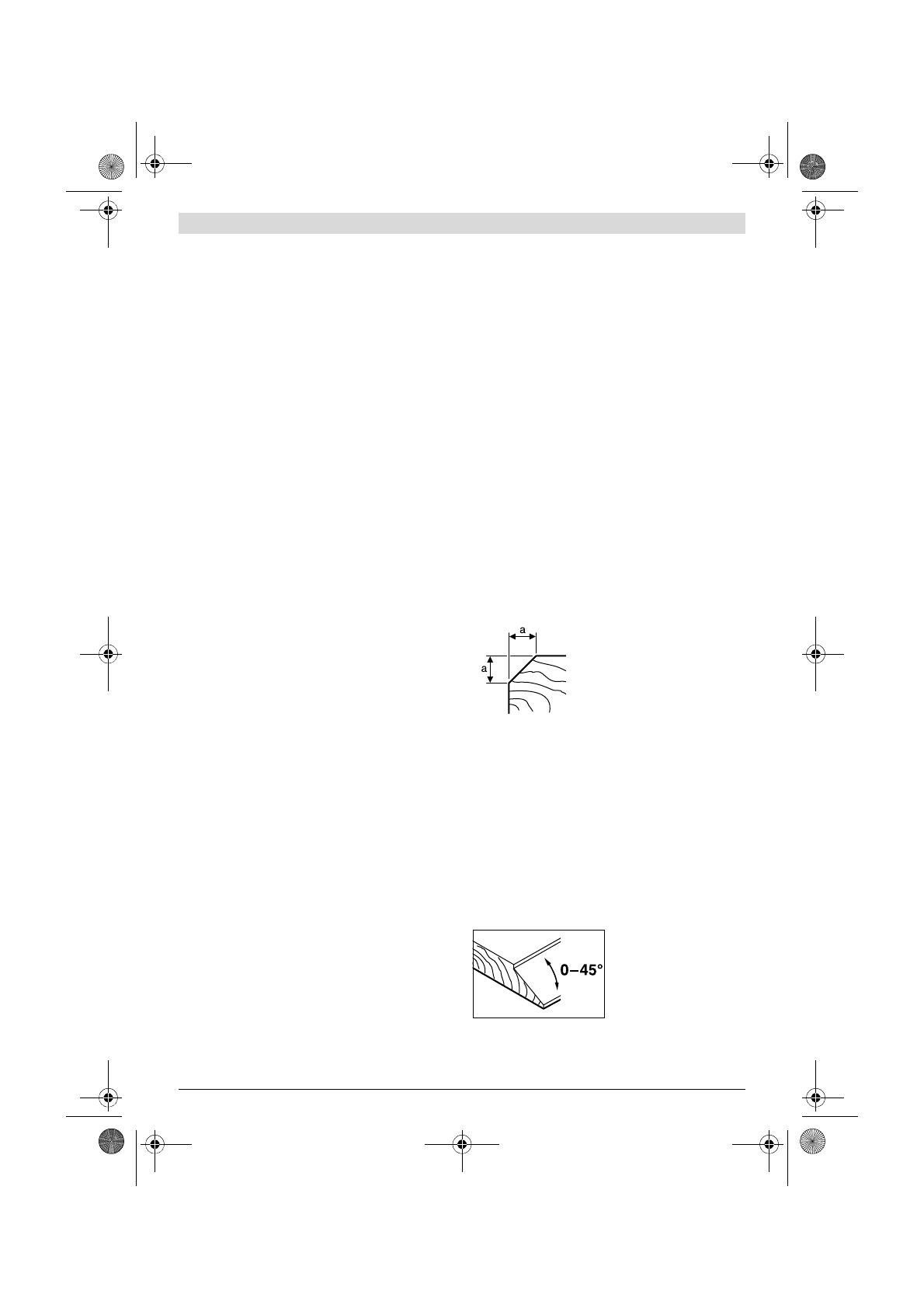

Beveling Edges (see figure F)

The V-grooves in the front planer base plate allow quick and

easy beveling of workpiece edges. Depending on required

bevel width, use the corresponding V-groove. For this, place

the planer with the V-groove onto the edge of the workpiece

and guide it along the edge.

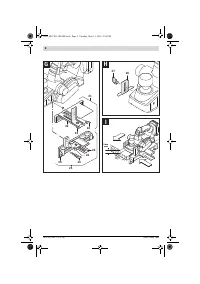

Planing with Parallel/Beveling Guide (see figure G – I)

Mount the parallel guide

21

or beveling guide

25

to the ma-

chine using the corresponding fastening bolt

24

. Depending

on the application, mount the rebating depth stop

28

with fas-

tening bolt

27

to the machine.

Loosen the locking nut

23

and adjust the requested rebating

width on the scale

22

. Tighten the locking nut

23

again.

Adjust the requested rebating depth accordingly with the re-

bating depth stop

28

.

Carry out the planing procedure several times until the re-

quested rebating depth is reached. Guide the planer applying

sideward supporting pressure.

Beveling with the Beveling Guide

When beveling rebates and

surfaces, adjust the required

slope angle with the angle ad-

justment

26

.

Groove to be used

Dimension a

(mm)

none

0 – 2.5

small

1.5 – 4.0

medium

2.0 – 4.5

large

3.0 – 5.5

OBJ_BUCH-1520-004.book Page 16 Tuesday, May 13, 2014 2:26 PM

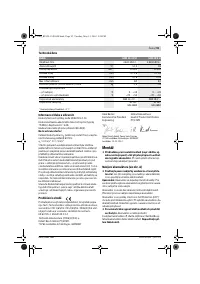

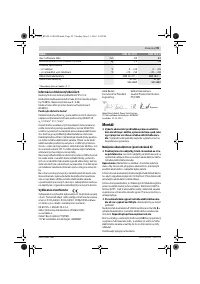

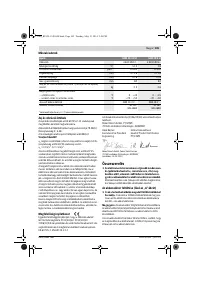

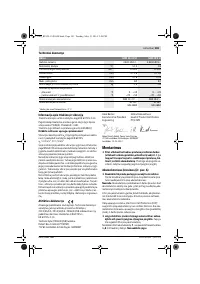

Характеристики

Остались вопросы?Не нашли свой ответ в руководстве или возникли другие проблемы? Задайте свой вопрос в форме ниже с подробным описанием вашей ситуации, чтобы другие люди и специалисты смогли дать на него ответ. Если вы знаете как решить проблему другого человека, пожалуйста, подскажите ему :)