Электропилы Bosch GTS 10 J Professional - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

English |

35

Bosch Power Tools

1 619 929 J53 | (12.5.11)

– Adjust the blade guard according to the workpiece height.

When sawing, the blade guard must always face lightly

against the workpiece.

– Switch on the machine.

– Saw through the workpiece applying uniform feed.

– Switch off the machine and wait until the saw blade has

come to a complete stop.

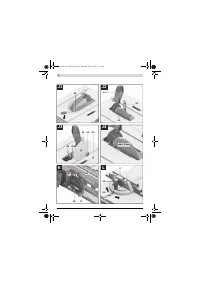

Sawing Bevel Angles

– Adjust the desired bevel angle. (see “Adjusting Bevel An-

gles”, page 33)

– Follow the worksteps in section “Sawing Straight Cuts” ac-

cordingly.

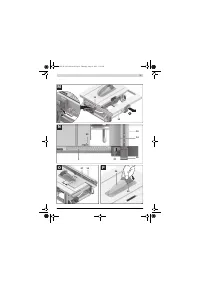

Sawing Mitre Angles (see figure S)

– Adjust the requested mitre angle (see “Adjusting Mitre An-

gles”, page 33)

– Place the workpiece against profile rail

28

.

The profile may not be on the cutting line. If so, loosen

knurled nut

53

and move the profile.

– Raise or lower the saw blade with the crank

19

so that the

upper saw teeth project approx. 5 mm above the work-

piece surface.

– Adjust the blade guard according to the workpiece height.

When sawing, the blade guard must always face lightly

against the workpiece.

– Switch on the machine.

– With one hand, press the workpiece against the profile rail

and with the other hand, slowly move the angle stop via

locking knob

49

toward the front in guide groove

5

.

– Switch off the machine and wait until the saw blade has

come to a complete stop.

Checking and Adjusting the Basic Adjustment

To ensure precise cuts, the basic adjustment of the machine

must be checked and adjusted as necessary after intensive

use.

A certain level of experience and appropriate specialty tools

are required for this.

A Bosch after-sales service station will handle this mainte-

nance task quickly and reliably.

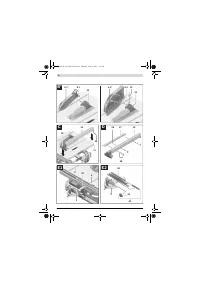

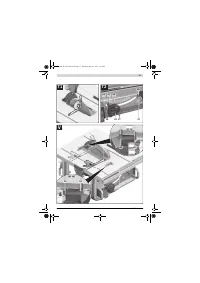

Setting the Stops for Standard 0 ° / 45 ° Bevel Angles

– Bring the power tool into the working position.

– Adjust to a 0 ° bevel angle.

– Tilt the protection guard

6.x

toward the rear to the stop.

Checking:

(see figure T1)

– Set an angle gauge to 90 ° and place it on the saw table

9

.

The leg of the angle gauge must be flush with the saw blade

26

over the complete length.

Adjusting:

(see figure T2)

– Loosen screw

54

.

The 0 ° stop

55

can now be moved.

– Loosen locking lever

17

.

– Move handwheel

18

toward the 0° stop until the leg of the

angle gauge is flush with the saw blade over the complete

length.

– Hold the handwheel in this position and tighten locking le-

ver

17

again.

– Tighten screw

54

again.

When the angle indicator

47

is not in line with the 0 ° mark of

scale

48

, loosen screw

56

with a commercially available Phil-

lips screwdriver and align the angle indicator alongside the 0 °

mark.

Repeat the above mentioned worksteps accordingly for the

45 ° bevel angle (loosening screw

57

; moving the 45° stop

58

). In this, the angle indicator

47

must not be misadjusted.

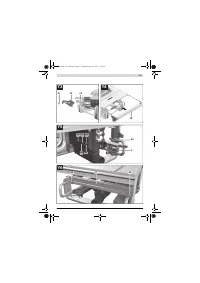

Parallelism of the Saw Blade to the Guide Grooves of the

Angle Stop (see figure U)

– Bring the power tool into the working position.

– Tilt the protection guard

6.x

toward the rear to the stop.

Checking:

– With a pencil, mark the first visible saw tooth on the left

side that projects above the insert plate.

– Set an angle gauge to 90 ° and place it on the edge of the

guide groove

5

.

– Move the leg of the angle gauge until it touches the marked

saw tooth, and read the clearance between saw blade and

guide groove.

– Turn the saw blade until the marked tooth projects above

the right side of the insert plate.

– Move the angle gauge alongside the guide groove to the

marked tooth.

– Measure the clearance between the saw blade and guide

groove again.

Both clearances measured must be identical.

Adjusting:

– Loosen Allen screws

59

at the front below the saw table

and Allen screws

60

at the rear below the saw table with

the supplied Allen key

21

.

– Carefully move the saw blade until it is parallel to guide

groove

5

.

– Retighten all screws

59

and

60

again.

Adjusting the Saw Table’s Clearance Indicator

(see figure V)

– Position the parallel guide on the right side of the saw

blade.

Move the parallel guide until the mark in the lens

27

indi-

cates 26 cm on the bottom scale.

To lock the parallel guide, press clamping handle

35

down

again.

– Loosen tensioning lever

15

and pull the table extension out

to the stop.

Checking:

On the upper scale

1

, clearance indicator

51

must indicate

the identical value as the mark in lens

27

on the bottom scale

1

.

Adjusting:

– Loosen screw

61

with a Phillips screwdriver and align

clearance indicator

51

alongside the 26 cm mark of the up-

per scale

1

.

Adjusting the Lens of the Parallel Guide (see figure W)

– Bring the power tool into the working position.

– Tilt the protection guard

6.x

toward the rear to the stop.

– Move parallel guide

10

from the right until it touches the

saw blade.

OBJ_BUCH-1325-002.book Page 35 Thursday, May 12, 2011 1:51 PM