Шуруповерты Dewalt 18 В XR FLEXVOLT ADVANTAGE XRP DCD999NT-XJ - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

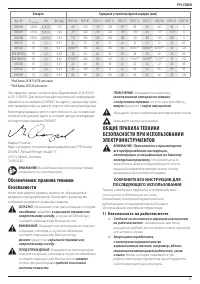

12

English

MAINTENANCE

Your power tool has been designed to operate over a long

period of time with a minimum of maintenance. Continuous

satisfactory operation depends upon proper tool care and

regular cleaning.

WARNING:

To reduce the risk of serious personal

injury, turn tool off and disconnect battery pack

before making any adjustments or removing/

installing attachments or accessories.

An accidental

start‑up can cause injury.

The charger and battery pack are not serviceable.

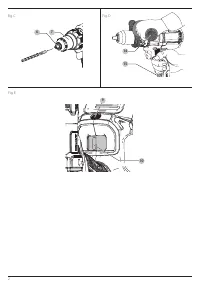

Hammerdrill Operation (Fig. A)

1. Select the desired speed/torque range using the gear shifter

to match the speed and torque to the planned operation.

Set the torque adjustment collar

5

to the hammer symbol.

2. Select the high speed 3 setting by sliding the gear shifter

8

back (away form the chuck).

3. When drilling, use just enough force on the hammer to

keep it from bouncing excessively. Prolonged and too much

force on the hammer will cause slower drilling speeds and

potential overheating.

4. Drill straight, keeping the bit at a right angle to the work. Do

not exert side pressure on the bit when drilling as this will

cause clogging of the bit flutes and a slower drilling speed.

5. When drilling deep holes, if the hammer speed starts to

drop off, pull the bit partially out of the hole with the tool

still running to help clear debris from the hole.

6. For masonry, use carbide‑tipped bits or masonry bits. A

smooth, even flow of dust indicates the proper drilling rate.

Drill Operation (Fig. A)

WARNING: TO REDUCE THE RISK OF PERSONAL

INJURY, ALWAYS

ensure workpiece is anchored or

clamped firmly. If drilling thin material, use a wood “back‑

up” block to prevent damage to the material.

1. Select the desired speed/torque range using the gear

shifter

8

to match the speed and torque to the planned

operation. Set the torque adjustment collar

5

to the

drill symbol.

2. For WOOD, use twist bits, spade bits, power auger bits or

hole saws. For METAL, use high‑speed steel twist drill bits

or hole saws. Use a cutting lubricant when drilling metals.

The exceptions are cast iron and brass which should be

drilled dry.

3. Always apply pressure in a straight line with the bit. Use

enough pressure to keep the drill bit biting, but do not push

hard enough to stall the motor or deflect the bit.

4. Hold tool firmly with both hands to control the twisting

action of the drill.

5.

iF DRill sTAlls,

it is usually because it is being

overloaded.

RElEAsE TRiggER iMMEDiATElY,

remove

drill bit from work, and determine cause of stalling.

DO nOT

CliCK TRiggER OFF AnD On in An ATTEMPT TO sTART

A sTAllED DRill – This CAn DAMAgE ThE DRill.

6. Keep the motor running when pulling the bit back out of a

drilled hole. This will help prevent jamming.

Screwdriver Operation (Fig. A)

1. Select the desired speed/torque range using the

three‑speed gear shifter

8

on the top of the tool. If using

the torque adjustment collar

5

, initially set the three‑speed

gear shifter to speed 2 or 3. This ensures effective control

over the fastener allowing the screw to be seated correctly

and set to specification. Speed 1 will provide the same

clutching torque as speeds 2 and 3. However, for optimum

performance of the electronic clutch, speeds 2 and

3 are preferred.

nOTE:

Use the lowest torque setting (1) first and increase

the number through to the highest setting (11) to seat the

fastener at the desired depth. The lower the number, the

lower the torque output.

2. Reset the torque adjustment collar

5

to the appropriate

number setting for the torque desired. Make a few practice

runs in scrap or unseen areas to determine the proper

position of the torque adjustment collar.

nOTE:

The torque adjustment collar may be set to any number

at any time.

Proper Hand Position (Fig. D)

WARNING:

To reduce the risk of serious personal injury,

ALWAYS

use proper hand position as shown.

WARNING:

To reduce the risk of serious personal injury,

ALWAYS

hold securely in anticipation of a sudden reaction.

Proper hand position requires one hand on the main

handle

15

, with the other hand on the side handle

14

to

control the twisting action of the drill.

OPERATION

Instructions for Use

WARNING:

Always observe the safety instructions and

applicable regulations.

WARNING:

To reduce the risk of serious personal

injury, turn tool off and disconnect battery pack

before making any adjustments or removing/

installing attachments or accessories.

An accidental

start‑up can cause injury.

1. Turn tool off and disconnect tool from power source.

2. Grasp the black sleeve of the chuck with one hand and

use the other hand to secure the tool. Rotate the sleeve

anticlockwise (as viewed from the front) far enough to

accept the desired accessory.

3. Insert the accessory about 19 mm into the chuck and

tighten securely by rotating the chuck sleeve clockwise

with one hand while holding the tool with the other hand.

Continue to rotate the chuck sleeve until several ratchet

clicks are heard to ensure full gripping power.

nOTE:

Be sure to tighten chuck with one hand on

the chuck sleeve and one hand holding the tool for

maximum tightness.

To release the accessory, repeat steps 1 and 2 above.

Содержание

- 17 ОБЩИЕ ПРАВИЛА ТЕХНИКИ; СОХРАНИТЕ ВСЕ ИНСТРУКЦИИ ДЛЯ; Батареи

- 18 ) Эксплуатация электроинструмента и уход

- 19 ) Использование аккумуляторных

- 20 Зарядные устройства; Электробезопасность; Использование удлинительного кабеля; СОХРАНИТЕ НАСТОЯЩЕЕ РУКОВОДСТВО; Остаточные риски

- 21 Работа с зарядным устройством

- 22 Аккумуляторные батареи; ВНИМАТЕЛЬНО ПРОЧТИТЕ ВСЕ ИНСТРУКЦИИ; Инструкции по очистке зарядного устройства; Температурная задержка; Крепление на стену

- 23 Транспортировка батареи FlEXVOlT; эксплуатация; Режим транспортировки:; Транспортировка

- 24 Маркировка на инструменте; Тип батареи; Рекомендации по хранению

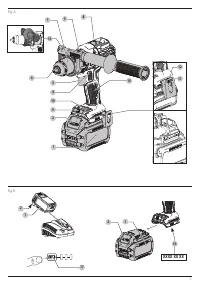

- 25 Дополнительные принадлежности; СБОРКА И РЕГ УЛИРОВКА; компоненты; Назначение; НЕ исПОЛЬЗуйТЕ

- 27 Режим фонаря

- 29 Защита окружающей среды; Чистка