Шлифмашины VERTO 51G203 - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

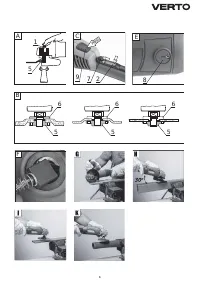

13

The wheel is removed in the reverse order. During installation, the wheel

should be pressed against the surface of the inner flange (

6

) and seated

centrally in the neck.

INSTALLING THE WORKING TOOLS WITH THREADED HOLES

•

Press the spindle lock button (

1

).

•

Remove a previously installed working tool, if it is installed.

•

Both flanges should be removed before installation – the inner flange

(

6

) and outer flange (

5

).

•

Put the threaded part of a working tool onto the spindle and slightly

tighten.

Working tools with threaded holes are removed in the reverse order.

INSTALLING THE ANGLE GRINDER ON A TRIPOD FOR ANGLE

GRINDERS

The angle grinder can be used on a dedicated tripod for angle grinders,

provided that it is correctly installed according to instructions of the

manufacturer of a tripod.

OPERATION / ADJUSTMENTS

Before the grinder is used, check condition of the grinding wheel.

Do not use chipped, broken or otherwise damaged grinding wheels.

Worn grinding wheel or brush should be immediately replaced with

new one before use. Once your work is completed, you should

switch off the grinder and wait until it comes to a complete stop.

Only then the grinder can be put aside. Do not brake a rotating

grinding wheel by pressing it against a workpiece.

• Do not overload the grinder. The weight of the power tool exerts

sufficient pressure to efficiently work with the tool. Overloading

and excessive pressure may lead to dangerous cracking of the

working tool.

• If the grinder is dropped during operation, it should be checked

and a working tool might need to be replaced, when it is damaged

or deformed.

• Never strike the workpiece with a working tool.

• Do not use the grinding wheel for hammering or stripping of the

workpiece, especially when corners, sharp edges are worked, etc.

(this may cause loss of control of the power tool and recoil).

• Do not use discs from circular saws intended for wood cutting.

Failure to observe this recommendation may result in recoil of the

power tool, loss of control and may lead to injuries of the operator.

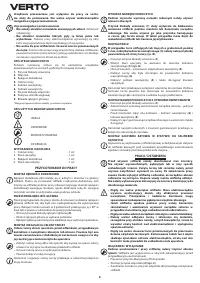

SWITCHING ON /SWITCHING OFF

When the grinder is switched on and operated, it should be held

with both hands.

The grinder is equipped with the switch protecting

against accidental activation.

•

Move the lever switch (

7

) forward.

•

Press the switch button (

2

) (

fig. C

).

•

When the switch button (

2

) is released, the grinder stops.

Once the grinder is switched on, wait until the grinding wheel

reaches maximum speed and only then you can begin to work.

During operation do not use the switch to switch the grinder on

and off. The grinder switch can be used only when the power tool is

moved away from the workpiece.

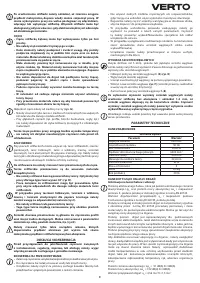

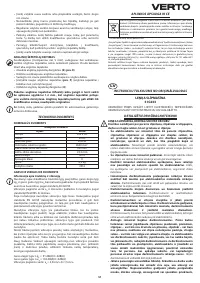

CUTTING

• The angle grinder can be used for cutting in a straight line only.

• Do not cut a workpiece holding it in your hands.

• Large workpiece should be supported. Make sure the support

points are located near the cutting line and at the ends of the

workpiece. A stably located workpiece will not tend to move,

when it is cut.

• Small workpieces should be fastened in a vice or using clamps, for

example. The workpiece should be fastened so that it is cut near

the fastening element. This will ensure higher cutting precision.

• Do not allow the cut-off wheel to vibrate or jump, since this will lower

the quality of cutting and may cause the cut-off wheel to break.

• Do not exert lateral pressure onto the cut-off wheel during cutting.

• A proper cut-off wheel should be used depending on a workpiece

type.

• When a workpiece is cut, it is recommended that a cutting

direction is the same as rotation direction of the cut-off wheel.

The cutting depth depends on a wheel diameter (

fig. G

).

•

Only wheels with nominal diameters not larger than recommended

for a given grinder model should be used.

•

Do not allow the fastening flanges to contact a workpiece in case of

deep cuts (e.g. sections, building blocks, bricks, etc.).

Cut-off wheels reach high temperatures during operation. It cannot

be touched with uncovered body parts, before they cool down.

GRINDING

Grinding wheel, cup-type grinding wheels, flap wheels, wheels with

abrasive fibre, wire brushes and flexible discs, etc. should be used for

grinding. Each type of discs and workpiece requires proper working

method and personal protective equipment.

Cut-off wheels should not be used for grinding.

Grinding discs are intended for removal of material with an edge

of the disc.

• Do not use the lateral surface for grinding. The optimum working

angle for this disc type is 30° (fig. H).

• Works related to grinding can be performed only, when proper

grinding discs are used for a given workpiece.

When flap wheels, discs with abrasive fibre and flexible discs for

sandpaper are used, attention should be paid to the proper tool

angle (fig. I).

• Do not grind with the entire surface of a wheel.

• This disc type should be used for working flat surfaces.

Wire brushes are mainly used for cleaning sections and hard-to-

reach spaces. They can be used to remove rust, painting coats, etc.

from a workpiece surface (fig. K).

Only such working tools can be used, whose permissible rotational

speed is higher or equal to the maximum no load speed of the grinder.

OPERATION AND MAINTENANCE

Before any operations related to installation, adjustment, repairs or

maintenance are commenced, the plug of the power cord should be

disconnected from the socket.

MAINTENANCE AND STORAGE

•

It is recommended to clean the tool after each use.

•

Do not use water or other fluids for cleaning.

•

The tool should be cleaned with a dry piece of cloth or blown with

compressed air of low pressure.

•

Do not use any cleaning agents or solvents, since they may damage

plastic parts.

•

Venting slots in the motor housing should be cleaned on a regular

basis not to overload the tool.

•

When the power cord is damaged, it should be replaced with the

power cord of the same parameters. It should be performed by a

qualified professional or the tool should be delivered to an authorised

service shop.

•

When the commutator sparks excessively, have the condition of motor

carbon brushes checked by a qualified person.

•

The tool should be always stored in a dry place and out of reach of

children.

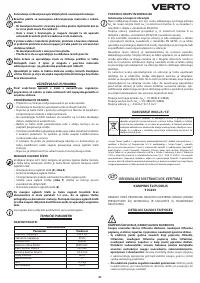

REPLACING THE CARBON BRUSHES

Worn (shorter than

5

mm), burnt or cracked motor carbon brushes

should be immediately replaced. Both carbon brushes should be always

replaced at the same time.

•

Remove the covers of the carbon brushes (

8

) (

fig. E

).

•

Remove the worn carbon brushes.

•

Remove any carbon dust using compressed air.

•

Insert new carbon brushes (

fig. F

) (brushes should easily slide into the

brush holders).

•

Fasten the covers of the carbon brushes (

8

).

After the carbon brushes are replaced, switch on the grinder with

no load and wait for 1-2 minutes to make the carbon brushes fit

the motor commutator. Carbon brushes should be replaced by a

qualified person using original spare parts only.

All types of faults and defects should be eliminated by an authorised

service of the manufacturer.

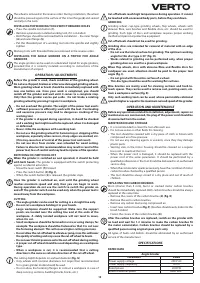

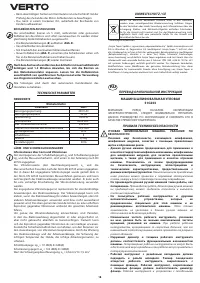

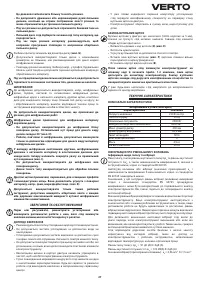

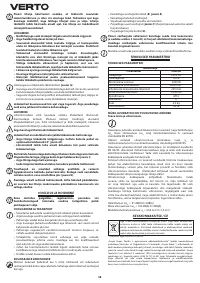

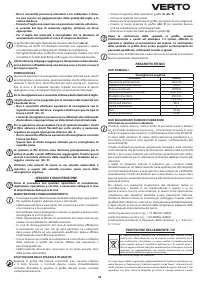

SPECIFICATIONS

RATED DATA

Angle Grinder

Parameter

Value

Power supply voltage

23

0 V AC

Power supply frequency

5

0 Hz

Rated power

2

000 W

Rated rotational speed

6

5

00 min

-1

Характеристики

Остались вопросы?Не нашли свой ответ в руководстве или возникли другие проблемы? Задайте свой вопрос в форме ниже с подробным описанием вашей ситуации, чтобы другие люди и специалисты смогли дать на него ответ. Если вы знаете как решить проблему другого человека, пожалуйста, подскажите ему :)