Шлифмашины VERTO 51G096 - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

11

TRANSLATION OF THE ORIGINAL INSTRUCTION

ANGLE GRINDER

5

1

G096

NOTE: BEFORE THE POWER TOOL IS USED FOR THE FIRST TIME, READ

THIS INSTRUCTION MANUAL AND KEEP IT FOR FUTURE REFERENCE.

DETAILED SAFETY REGULATIONS

ANGLE GRINDER, SAFETY WARNINGS

Safety guidelines for grinding, sanding with sandpaper, working

with wire brushes and cutting using the grinding wheel.

• This power tool can be used as a regular grinder, sander

for sanding with sandpaper, grinder for grinding with wire

brushes and for cutting with a cut-off wheel. Observe all safety

guidelines, instructions, descriptions and data provided with

the power tool.

Failure to observe the following recommendations

may cause danger of electric shock, fire and/or serious injuries.

• This power tool cannot be used for polishing.

When the power

tool is used for other works than it is designed for, it may contribute to

hazards and injuries.

• Do not use equipment, which is not designed and recommended

by the manufacturer specifically for this device.

The fact that it

can be fastened to the power tool, does not guarantee safe operation.

• The permissible rotational speed of a working tool used cannot

be lower than the maximum rotational speed given on the

power tool.

A working tool rotating faster than the permissible speed

may break and its parts may chip off.

• The outside diameter and thickness of a working tool must

correspond to dimensions of the power tool.

A working tool of

incorrect dimensions may not provide sufficient control and covering

of the power tool.

• Working tools with threaded inserts must perfectly fit the

thread in the spindle. In case of working tools that are fastened

using a flange, the hole diameter of a working tool must fit the

flange diameter.

Working tools, which cannot be precisely seated in

the power tool, rotate unevenly, vibrate heavily and may result in loss

of control over the power tool.

• Under no circumstances, should damaged working tools be

used. Before the power tool is used, accessories such as cut-off

wheels should be checked for chips and cracks, grinding wheels

should be checked for cracks, abrasion or heavy wear, while

wire brushes for loose or broken wires. When the power tool

or a working tool is dropped, it must be checked for damage

or another, undamaged tool should be used. If a working tool

is checked and fastened, the power tool should be switched on

for a minute at the highest speed, paying attention so that the

operator and bystanders are beyond the zone of the rotating

tool.

Damaged working tools often break in this test period.

• Always wear personal protective equipment. Depending on a

type of work, a full face mask, eye protection or safety glasses

should be worn. A dust mask, ear protection, protective gloves

or a special apron protecting against small particles of abrasive

material and workpiece should be worn, if needed.

Protect your

eyes against airborne foreign bodies occurring during operation. A

dust mask and protective mask for the respiratory system must filter

dust occurring during work. The influence of noise for a longer period

of time may lead to deterioration of the hearing.

• Always make sure bystanders are in a safe distance from the

power tool reach zone. All people staying in the vicinity of the

operating power tool must use personal protective equipment.

Chips of a workpiece or broken working tools may chip off and cause

injuries also beyond the direct reach zone.

• When works are performed, during which the power tool may

GB

encounter hidden electric conductors or own power cord,

the power tool should be held by the isolated surfaces of the

handle.

A contact with the power mains network may transfer voltage

onto metal parts of the power tool, which may result in electric shock.

• The power cord must be kept away from the rotating working

tools.

When the control over the tool is lost, the power cord may be cut

or caught, and your hand or the entire arm may get into the rotating

working tool.

• Do not put the power tool aside, before the working tool comes

to complete stop.

The rotating working tool may come in contact

with a surface, which it is put aside onto, and you may lose control over

the tool.

• Do not carry the power tool, which is in motion.

An accidental

contact with the rotating working tool may caught in your clothes and

drill into an operator’s body.

• Clean ventilation slots of the power tool on a regular basis.

The

motor blower sucks dust into the casing, while large accumulation of

metal dust may cause electric hazard.

• Do not use the power tool near flammable materials.

Sparks may

cause ignition.

• Do not use tools, which require liquid cooling agents.

The use of

water or other cooling agents may cause electric shocks.

Recoil and proper safety guidelines

•

Recoil is a sudden reaction of the power tool to seizure or blocking

of a rotating working tool, such a grinding wheel, cut-off wheel or

a wire brush, etc.

The seizure and blocking may suddenly stop a rotating working

tool. The power tool without control will be jerked in the opposite

direction to the working tool.

When the grinding wheel stops or catches in the workpiece, an

edge od the grinding wheel immersed in the workpiece may lock

and cause recoil or rejection. The movement of the grinding wheel

(towards or away from the operator) depends on the movement

of the grinding wheel in a place, where it is locked. The grinding

wheels may also break.

Recoil is a consequence of incorrect operation of the power tool.

This can be avoided by observing the following precautions.

• The power tool must be held firmly, while your body and hands

should be positioned to alleviate recoil. If the additional handle

is included as standard equipment, it should be used at all times

to provide the highest control over recoil forces or rejecting

moment during start-up.

An operator can take control of recoil and

jerking by taking proper precautions.

• Never hold your hands in the vicinity of rotating working tools.

A working tool may injure your hand as a result of recoil.

• Always stay away from the reach zone, in which the power tool

moves during recoil.

As a result of recoil, the power tool moves in

the opposite direction to the movement of the grinding wheel, where

it locks.

• Corners, sharp edges, etc. should be worked with special attention.

Recoil or locking of the working tools should be prevented.

A rotating working tool is more prone to seizure, when working angles,

corners, sharp edges or when it is rebound. This may result in loss of

control or recoil.

• Do not use discs for wood or toothed discs.

Working tools of this

type often cause recoil or loss of control over the working tool.

Special safety guidelines for grinding and cutting with the

grinding wheel.

• Always use the grinding wheel intended for a given power

tool and guard intended for a given grinding wheel.

Grinding

wheel that are not part of equipment of a given power tool may be

insufficiently covered or safe.

• Offset grinding wheels should be fastened so that their

grinding surface does not protrude beyond the protective

guard.

Incorrectly seated grinding wheel and protruding beyond the

edge of the protective guard may not be sufficiently covered.

• The guard must be secured to the power tool to ensure the

highest possible safety level and positioned so that the

uncovered part of the grinding wheel facing the operator is

as small as possible.

The guard protects the operator against chips,

accidental contact with the grinding wheel and sparks, which may set

clothing on fire.

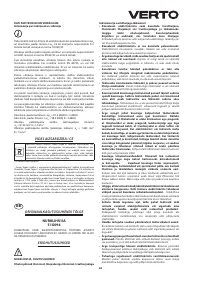

Характеристики

Остались вопросы?Не нашли свой ответ в руководстве или возникли другие проблемы? Задайте свой вопрос в форме ниже с подробным описанием вашей ситуации, чтобы другие люди и специалисты смогли дать на него ответ. Если вы знаете как решить проблему другого человека, пожалуйста, подскажите ему :)