Шуруповерты Makita G-серия HP488DWE - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

9 ENGLISH

Displayed

Number

Speed

Torque

Applicable

operation

1

Low

High

Heavy load-

ing operation

2

High

Low

Light loading

operation

To change the speed, switch off the tool first. Push the

speed change lever to display "2" for high speed or "1"

for low speed. Be sure that the speed change lever is

set to the correct position before operation.

If the tool speed is coming down extremely during the

operation with display "2", push the lever to display "1"

and restart the operation.

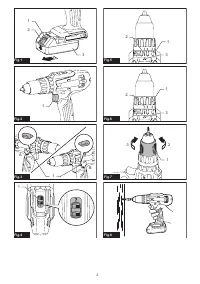

Selecting the action mode

CAUTION:

Always set the ring correctly to

your desired mode mark. If you operate the tool

with the ring positioned halfway between the

mode marks, the tool may be damaged.

►

Fig.5:

1.

Action mode changing ring

2.

Mark

3.

Arrow

This tool has three action modes.

•

Drilling mode (rotation only)

•

Hammer drilling mode (rotation with

hammering)

•

Screwdriving mode (rotation with clutch)

Select one mode suitable for your work. Turn the

action mode changing ring and align the mark that you

selected with the arrow on the tool body.

Adjusting the fastening torque

►

Fig.6:

1.

Adjusting ring

2.

Graduation

3.

Arrow

The fastening torque can be adjusted in 16 levels by

turning the adjusting ring. Align the graduations with the

arrow on the tool body. You can get the minimum fas

-

tening torque at 1 and maximum torque at 16.

Before actual operation, drive a trial screw into your mate-

rial or a piece of duplicate material to determine which

torque level is required for a particular application.

ASSEMBLY

CAUTION:

Always be sure that the tool is

switched off and the battery cartridge is removed

before carrying out any work on the tool.

Installing or removing driver bit/drill bit

CAUTION:

After inserting the driver bit, make

sure that it is firmly secured. If it comes out, do not

use it.

►

Fig.7:

1.

Sleeve

2.

Open

3.

Close

Turn the sleeve counterclockwise to open the chuck

jaws. Place the driver bit/drill bit in the chuck as far

as it will go. Turn the sleeve clockwise to tighten the

chuck. To remove the driver bit/drill bit, turn the sleeve

counterclockwise.

OPERATION

CAUTION:

Always insert the battery cartridge

all the way until it locks in place.

If you can see the

red indicator on the upper side of the button, it is not

locked completely. Insert it fully until the red indicator

cannot be seen. If not, it may accidentally fall out of

the tool, causing injury to you or someone around

you.

CAUTION:

When the speed comes down

extremely, reduce the load or stop the tool to

avoid the tool damage.

Hold the tool firmly with one hand on the grip and the

other hand on the bottom of the battery cartridge to

control the twisting action.

Screwdriving operation

CAUTION:

Adjust the adjusting ring to the

proper torque level for your work.

CAUTION:

Make sure that the driver bit is

inserted straight in the screw head, or the screw

and/or driver bit may be damaged.

First, turn the action mode changing ring so that the

arrow on the tool body points to the

marking.

Place the point of the driver bit in the screw head and

apply pressure to the tool. Start the tool slowly and then

increase the speed gradually. Release the switch trigger

as soon as the clutch cuts in.

►

Fig.8

NOTE:

When driving wood screw, pre-drill a pilot hole

2/3 the diameter of the screw. It makes driving easier

and prevents splitting of the workpiece.

Hammer drilling operation

CAUTION:

There is a tremendous and sud

-

den twisting force exerted on the tool/drill bit

at the time of hole breakthrough, when the hole

becomes clogged with chips and particles, or

when striking reinforcing rods embedded in the

concrete.

First, turn the action mode changing ring so that the

arrow on the tool body points to the

marking. The

adjusting ring can be aligned in any torque levels for

this operation.

Be sure to use a tungsten-carbide tipped drill bit.

Position the drill bit at the desired location for the hole,

then pull the switch trigger. Do not force the tool. Light

pressure gives best results. Keep the tool in position

and prevent it from slipping away from the hole.

Do not apply more pressure when the hole becomes

clogged with chips or particles. Instead, run the tool at

an idle, then remove the drill bit partially from the hole.

By repeating this several times, the hole will be cleaned

out and normal drilling may be resumed.