Шлифмашины Ryobi) (5133005403) - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

4

Original Instructions

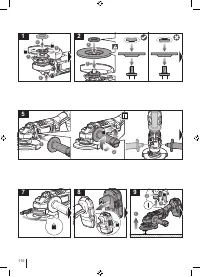

operating procedures or conditions and can be avoided by

taking proper precautions as given below.

■

Maintain a firm grip with both hands on the power

tool and position your body and arms to allow you to

resist kickback forces. Always use auxiliary handle,

if provided, for maximum control over kickback or

torque reaction during start-up.

The operator can

control torque reactions or kickback forces, if proper

precautions are taken.

■

Never place your hand near the rotating accessory.

Accessory may kickback over your hand.

■

Do not position your body in the area where power

tool will move if kickback occurs.

Kickback will propel

the tool in direction opposite to the wheel’s movement at

the point of snagging.

■

Use special care when working corners, sharp

edges, etc. Avoid bouncing and snagging the

accessory.

Corners, sharp edges or bouncing have a

tendency to snag the rotating accessory and cause loss

of control or kickback.

■

Do not attach a saw chain woodcarving blade,

segmented diamond wheel with a peripheral gap

greater than 10 mm or toothed saw blade.

Such

blades create frequent kickback and loss of control.

Safety warnings specific for grinding and cutting-off

operations

■

Use only wheel types that are specified for your

power tool and the specific guard designed for the

selected wheel.

Wheels for which the power tool was

not designed cannot be adequately guarded and are

unsafe.

■

The grinding surface of centre depressed wheels

must be mounted below the plane of the guard lip.

An improperly mounted wheel that projects through the

plane of the guard lip cannot be adequately protected.

■

The guard must be securely attached to the power

tool and positioned for maximum safety, so the least

amount of wheel is exposed towards the operator.

The guard helps to protect the operator from broken

wheel fragments, accidental contact with wheel and

sparks that could ignite clothing.

■

Wheels must be used only for specified applications.

For example: do not grind with the side of cut-

off wheel.

Abrasive cut-off wheels are intended for

peripheral grinding, side forces applied to these wheels

may cause them to shatter.

■

Always use undamaged wheel flanges that are of

correct size and shape for your selected wheel.

Proper wheel flanges support the wheel thus reducing

the possibility of wheel breakage. Flanges for cut-off

wheels may be different from grinding wheel flanges.

■

Do not use worn down wheels from larger power

tools.

A wheel intended for larger power tool is not

suitable for the higher speed of a smaller tool and may

burst.

■

When using dual purpose wheels always use the

correct guard for the application being performed.

Failure to use the correct guard may not provide the

desired level of guarding, which could lead to serious

injury.

Additional safety warnings specific for cutting-off

operations

■

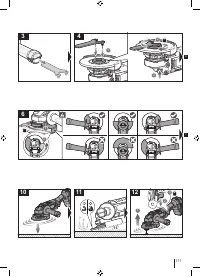

Do not “jam” the cut-off wheel or apply excessive

pressure. Do not attempt to make an excessive

depth of cut.

Overstressing the wheel increases the

loading and susceptibility to twisting or binding of the

wheel in the cut and the possibility of kickback or wheel

breakage.

■

Do not position your body in line with and behind

the rotating wheel.

When the wheel, at the point of

operation, is moving away from your body, the possible

kickback may propel the spinning wheel and the power

tool directly at you.

■

When the wheel is binding or when interrupting a cut

for any reason, switch off the power tool and hold

it motionless until the wheel comes to a complete

stop. Never attempt to remove the cut-off wheel

from the cut while the wheel is in motion otherwise

kickback may occur.

Investigate and take corrective

action to eliminate the cause of wheel binding.

■

Do not restart the cutting operation in the workpiece.

Let the wheel reach full speed and carefully re-enter

the cut.

The wheel may bind, walk up or kickback if the

power tool is restarted in the workpiece.

■

Support panels or any oversized workpiece to

minimize the risk of wheel pinching and kickback.

Large workpieces tend to sag under their own weight.

Supports must be placed under the workpiece near the

line of cut and near the edge of the workpiece on both

sides of the wheel.

■

Use extra caution when making a “pocket cut” into

existing walls or other blind areas.

The protruding

wheel may cut gas or water pipes, electrical wiring or

objects that can cause kickback.

■

Do not attempt to do curved cutting.

Overstressing

the wheel increases the loading and susceptibility

to twisting or binding of the wheel in the cut and the

possibility of kickback or wheel breakage, which can

lead to serious injury.

ADDITIONAL SAFETY WARNINGS

■

Clamp the workpiece with a clamping device. Unclamped

workpieces can cause severe injury and damage.

■

Injuries may be caused, or aggravated, by prolonged

use of a tool. When using any tool for prolonged periods,

ensure you take regular breaks.

■

Ambient temperature range for tool during operation is

between

0

°C and

40

°C.

■

Ambient temperature range for tool storage is between

0

°C and

40

°C.

■

The recommended ambient temperature range for the

charging system during charging is between

10

°C and

38

°C.

ADDITIONAL BATTERY SAFETY WARNINGS

To reduce the risk of

fi

re, personal injury, and product

damage due to a short circuit, never immerse your tool,

battery pack or charger in

fl

uid or allow a

fl

uid to

fl

ow inside

them. Corrosive or conductive

fl

uids, such as seawater,

certain industrial chemicals, and bleach or bleach-containing

products, etc., can cause a short circuit.

■

Ambient temperature range for battery during use is

between

0

°C and

40

°C.

■

Ambient temperature range for battery storage is

between

0

°C and

20

°C.

TRANSPORTING LITHIUM BATTERIES

Transport the battery in accordance with local and national

provisions and regulations.

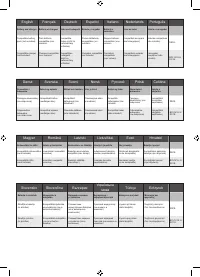

Характеристики

Остались вопросы?Не нашли свой ответ в руководстве или возникли другие проблемы? Задайте свой вопрос в форме ниже с подробным описанием вашей ситуации, чтобы другие люди и специалисты смогли дать на него ответ. Если вы знаете как решить проблему другого человека, пожалуйста, подскажите ему :)