Перфораторы Bosch GBH 240F - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

English |

15

Bosch Power Tools

1 609 92A 3SE | (24.4.17)

Noise/Vibration Information

Sound emission values determined according to

EN 60745-2-6.

Typically the A-weighted noise levels of the product are:

Sound pressure level 92.5 dB(A); Sound power level

103.5 dB(A). Uncertainty K = 3 dB.

Wear hearing protection!

Vibration total values a

h

(triax vector sum) and uncertainty K

determined according to EN 60745-2-6:

Hammer drilling into concrete: a

h

= 13.1 m/s

2

, K = 1.5 m/s

2

Chiselling: a

h

= 13.9 m/s

2

, K = 1.5 m/s

2

The vibration level given in this information sheet has been

measured in accordance with a standardised test given in

EN 60745 and may be used to compare one tool with anoth-

er. It may be used for a preliminary assessment of exposure.

The declared vibration emission level represents the main ap-

plications of the tool. However if the tool is used for different

applications, with different accessories or insertion tools or is

poorly maintained, the vibration emission may differ. This

may significantly increase the exposure level over the total

working period.

An estimation of the level of exposure to vibration should also

take into account the times when the tool is switched off or

when it is running but not actually doing the job. This may sig-

nificantly reduce the exposure level over the total working

period.

Identify additional safety measures to protect the operator

from the effects of vibration such as: maintain the tool and the

accessories, keep the hands warm, organisation of work pat-

terns.

Assembly

Before any work on the machine itself, pull the mains

plug.

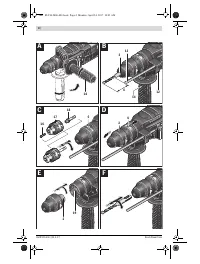

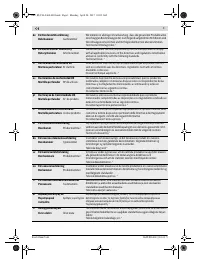

Auxiliary Handle

Operate your machine only with the auxiliary handle

14.

Changing the position of the auxiliary handle

(see figure A)

The auxiliary handle

14

can be set to any position for a secure

and low-fatigue working posture.

– Turn the bottom part of the auxiliary handle

14

in counter-

clockwise direction and swivel the auxiliary handle

14

to

the desired position. Then retighten the bottom part of the

auxiliary handle

14

by turning in clockwise direction.

Pay attention that the clamping band of the auxiliary

handle is positioned in the groove on the housing as

intended for.

Adjusting the Drilling Depth (see figure B)

The required drilling depth

X

can be set with the depth stop

13

.

– Press the button for the depth stop adjustment

12

and

insert the depth stop into the auxiliary handle

14

.

The knurled surface of the depth stop

13

must face down-

ward.

– Insert the SDS-plus drilling tool to the stop into the SDS-

plus tool holder

3

. Otherwise, the movability of the SDS-

plus drilling tool can lead to incorrect adjustment of the

drilling depth.

– Pull out the depth stop until the distance between the tip of

the drill bit and the tip of the depth stop corresponds with

the desired drilling depth

X

.

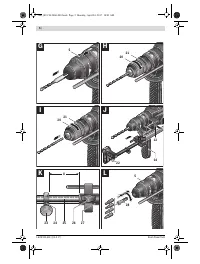

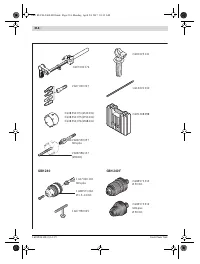

Selecting Drill Chucks and Tools

For hammer drilling and chiselling, SDS-plus tools are re-

quired that are inserted in the SDS-plus drill chuck.

For drilling without impact in wood, metal, ceramic and

plastic as well as for screwdriving, tools without SDS-plus are

used (e. g., drill bits with cylindrical shank). For these tools, a

keyless chuck or a key type drill chuck are required.

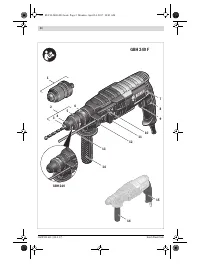

GBH 240 F: The SDS-plus quick change chuck

2

can easily be

replaced against the quick change keyless chuck

1

provided.

Changing the Key Type Drill Chuck (GBH 240)

To work with tools without SDS-plus (e. g., drills with cylindri-

cal shank), a suitable drill chuck must be mounted (key type

drill chuck or keyless chuck, accessories).

Mounting the Key Type Drill Chuck (see figure C)

– Screw the SDS-plus adapter shank

18

into a key type drill

chuck

17

. Secure the key type drill chuck

17

with the

securing screw

16

.

Please observe that the securing

screw has a left-hand thread.

Inserting the Key Type Drill Chuck (see figure C)

– Clean the shank end of the adapter shank and apply a light

coat of grease.

– Insert the key type drill chuck with the adapter shank into

the tool holder with a turning motion until it automatically

locks.

– Check the locking effect by pulling the key type drill chuck.

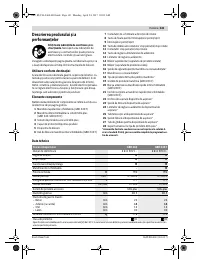

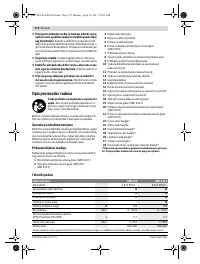

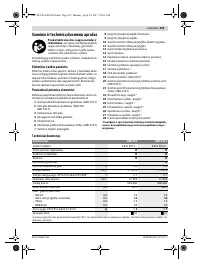

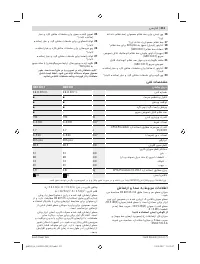

Drilling diameter, max.:

– Concrete

– Brickwork (with core bit)

– Steel

– Wood

mm

mm

mm

mm

24

68

13

30

24

68

13

30

Weight according to EPTA-Procedure 01:2014

kg

2.8

2.9

Protection class

/

II

/

II

Rotary Hammer

GBH 240

GBH 240 F

The values given are valid for a nominal voltage [U] of 230 V. For different voltages and models for specific countries, these values can vary.

OBJ_BUCH-2460-003.book Page 15 Monday, April 24, 2017 10:03 AM

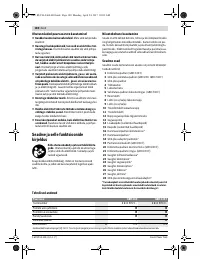

Содержание

- 118 Указания по технике безопасности для

- 119 Описание продукта и услуг; Применение по назначению

- 120 Технические данные; Сборка; Дополнительная рукоятка

- 121 Выбор сверлильного патрона и инструмента

- 123 Работа с инструментом; Включение электроинструмента

- 124 Техобслуживание и сервис; Техобслуживание и очистка

Характеристики

Остались вопросы?Не нашли свой ответ в руководстве или возникли другие проблемы? Задайте свой вопрос в форме ниже с подробным описанием вашей ситуации, чтобы другие люди и специалисты смогли дать на него ответ. Если вы знаете как решить проблему другого человека, пожалуйста, подскажите ему :)