Водонагреватели TesyGCA 1015 - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

Instructions for use and maintenance

7

EN

English

II.

TECHNICAL PARAMETERS

1.

Nominal volume V, liters - see the appliance’s rating plate

2.

Nominal voltage - see the appliance’s rating plate

3.

Nominal power consumption - see the appliance’s rating plate

4.

Nominal pressure - see the appliance’s rating plate

This is not the water mains pressure. This is the pressure that is

announced for the appliance and refers to the requirements of the

safety standards.

5.

Water heater type - closed type accumulating water heater, with

thermal insulation

6.

Daily energy consumption – see Annex I

7.

Rated load profile - see Annex I

8.

Quantity of mixed water at 40°C V40 litres - see Annex I

9.

Maximum temperature of the thermostat - see Annex I

10.

Default temperature settings - see Annex I

11.

Energy efficiency during water heating - see Annex I.

III.

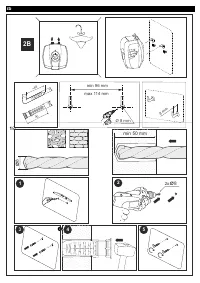

DESCRIPTION AND PRINCIPLE OF OPERATION

The appliance consists of a body, flange, plastic control panel, safety

return valve.

1.

The body consists of a steel reservoir (water tank) and plastic

housing (outer shell) with thermal insulation placed in-between,

and two pipes with thread G ½“, for cold water supply (marked

with a blue ring) and hot water discharge (marked with a red ring).

The inner reservoir is made of steel proved against corrosion by a

special glass-ceramic coating.

2.

The flange is outfitted with: electric heater and thermostat. The water

heaters with glass-ceramics coating are outfitted with a magnesium

protector.

The electric heater is used for heating the water in the tank and is managed

by the thermostat, which automatically maintains the set temperature.

The thermostat has a built in overheating safety device, which switches of

power to the heater when the water temperature reaches excessive values

.

3.

The safety-return valve prevents the appliance's complete

emptying in the event of cold water supply interruption. The

valve protects the appliance from pressure increases higher than

the allowed value during heating (! pressure will increase when

temperature increases), by releasing the excess pressure through

the drain outlet. Water dropping out through the drains during

the warming process is a normal event that must be taken into

consideration when the boiler is installed.

ATTENTION! The safety-return valve cannot protect the appliance in the

event of water mains pressure in excess of the acceptable pressure

stated for the appliance.

IV.

INSTALLATION AND SWITCH ON

Attention! Improper installation and connection of the appliance may make it

hazardous for the health and life of consumers. It may cause grievous and

permanent consequences, including but not limited to physical injuries and/

or death. Improper installation and connection of the appliance may also lead to

damage to the consumers’ property /damage and/ or destruction/, or to that of third

persons, as a result of, but not limited to flooding, explosion and/or fire.

Installation, connection to the main water and power supply, and putting into

operation must be carried out by certified electricians and technical personnel

certified in installation of this category of appliances, who have obtained their

license in the state where the installation and commissioning of the appliance are

carried out, and in compliance with its local legislation.

1.

Installation

We recommend installation of the device at close proximity to locations where

hot water is used, in order to reduce heat losses during water transportation.

The selected location must exclude the possibility of water spray originating

from the showerhead or other water contacts.

•

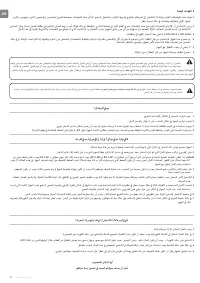

Appliances designed for installation

above sinks

are assembled in such a

manner that the outlet/inlet pipes are pointed downwards (to the floor of the

premise).

The appliance is affixed to a wall by means of mounting brackets attached to

the unit's body. Two hooks are used to fix the appliance (min. Ø 4 mm) firmly

on the wall (included in the mounting set).

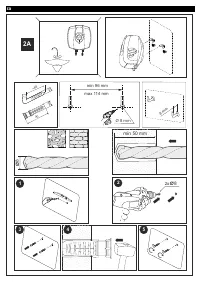

•

Appliances designed for installation

under sinks

are assembled in such

a manner that the outlet/inlet pipes are pointed upwards (to the ceiling of the

premise).

The appliances can be placed standing on the floor or mounted on the wall.

In case you want to mount the appliance on the wall, the suspension must be

done with two hooks (

min. Ø 4 mm

) securely attached to the wall.

IMPORTANT: The type of appliance designed to be installed UNDER /

ABOVE a sink is marked on the appliance.

The bearing plank construction for boilers installed above / under sinks is

universal and allows the space between hooks to vary between 96 and

114mm. (fig.2).

For clear understanding of wall installation schemes, please refer to fig.2 (A

above sink, B under sink and C for floor installation).

ATTENTION! In order to prevent injury to user and third persons in the

event of faults in the hot water supply system, the appliance must be

mounted in premises outfitted with floor hydro insulation and sewer drainage.

Don't place objects, which are not waterproof under the appliance under any

circumstances. In the event of mounting the appliance in premises without floor

hydro insulation, a protective tank with a sewer discharge drainage must be

placed under the appliance.

Notice: the set does not include a protective tub and the user

must select the same.

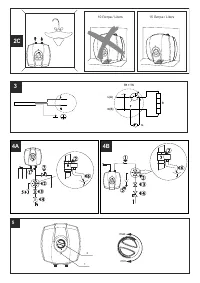

2.

Water heater connection to the water supply system

Fig.4a

- installation scheme above sink

Fig.4b

- installation scheme under sink

Where: 1 – input pipe, 2 – safety valve (0.8 MPa), 3 – reduction

valve (if the water supply pressure exceeds 0,6 MPa), 4 – stop

valve, 5 – bell-mouth discharge to the sewer, 6 – hose; 7 - Drain

water tap.

Upon connecting the water heater to the water supply system, take

care of the indicative color markings /rings/ of the pipes:

BLUE

- for cold /in-flowing/ water,

RED

- for hot /out-flowig/ water.

The mounting of the safety return-valve supplied with the water

heater is obligatory. The safety return-valve must be installed on the

cold water supply pipe, according to the arrow stamped on its body

that indicates the supplied water direction.

Exception: If the local regulations (norms) require the usage of

another protection valve or mechanism (in accordance with EN

1487 or EN 1489), then it must be bought additionally. For

mechanisms operating in accordance with EN 1487 the announced

operational pressure must be no more than 0.7 MPa. For other

protection valves, the pressure at which they are calibrated must be

0.1 MPa lower than the one marked on the appliance’s sign. In

these cases the safety valve which the appliance is supplied with

should not be used

.

ATTENTION! Other type of stopping armature is not allowed between

the protection return valve (the protective device) and the appliance.

ATTENTION! Any other /old/ safety return-valves may lead to a failure of

your appliance, therefore they must be removed.

ATTENTION! Fixing the safety return-valve to threads longer than 10

mm is not allowed, as it could damaged the valve and could make the

use of your appliance dangerous.

ATTENTION! The safety valve and the pipe between the valve and the

water heater must be protected from freezing. During hose draining - its

free end must be always open to the atmosphere (not to be immersed). Make

sure that the hose is also protected from freezing.

The boiler is filled with water by opening the tap on the cold water

supply system and the tap on the hot water mixing faucet. After the

filling process is complete, a constant stream of water should flow

from the water-mixing faucet. Now you can shut the hot water tap

on the mixing faucet.

When you must empty the water heater, you should first cut it off

the power supply.

Draining procedure for boilers designed to be installed ABOVE

SINKS:

1.

First shut the cold water supply valve

2.

Open the hot water valve on the mixing-faucet

3.

The water tap 7 (

fig 4a

) must be opened to drain the water from

water tank. If there is no such tap build in the pipe line, than the

water can be drain directly from inlet pipe of water tank after when

you disconnect it from water main

IMPORTANT: When draining the boiler, take measures to

prevent damages caused by the flowing water.

Draining procedure for boilers designed to be installed UNDER

SINKS:

1.

Switch the boiler off the power supply network.

2.

Dismantle the connecting water fittings from the boiler.

3.

Disassemble the boiler from its installation place, turn it so the

pipes point to the floor and pour the water in a vessel you have

prepared for the purpose. Wait until all the water drains out of the

Характеристики

Остались вопросы?Не нашли свой ответ в руководстве или возникли другие проблемы? Задайте свой вопрос в форме ниже с подробным описанием вашей ситуации, чтобы другие люди и специалисты смогли дать на него ответ. Если вы знаете как решить проблему другого человека, пожалуйста, подскажите ему :)