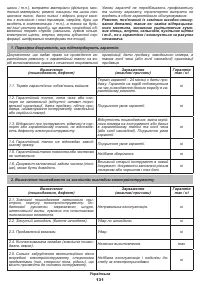

Шуруповерты DWT BM-1050 M 5.1.6 - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

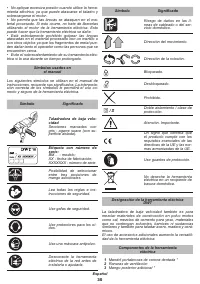

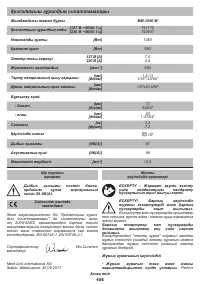

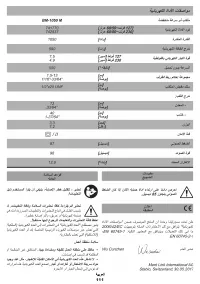

18

English

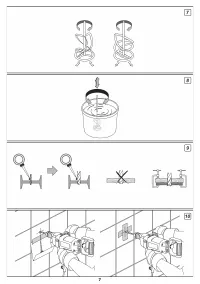

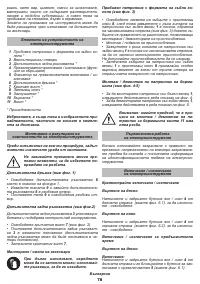

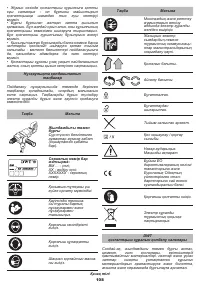

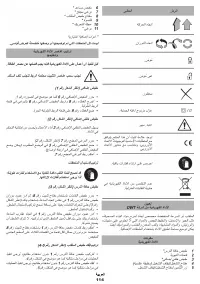

Mounting / replacement of accessories

With long-term use the drill bit may be-

come very warm; use gloves to remove

it.

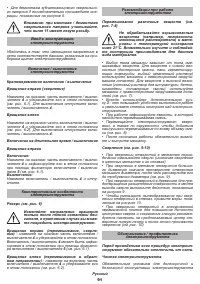

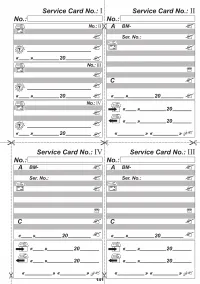

Gear rim chuck (see fig. 3)

•

Release the cams grip with clamping wrench

8

, then

rotate the quill of gear rim chuck

1

counter-clockwise

with your hand (see fig. 3) until the cams move apart

at the distance allowing an accessory to be mounted /

replaced�

•

Mount / replace an accessory�

•

Rotate the quill of gear rim chuck

1

clockwise with

your hand in order to lock the accessory mounted� Do

not allow the accessory to become distorted�

•

Tighten the cams of gear rim chuck

1

with clamping

wrench

8

applying a similar torque to each of the three

openings on the side surface of the chuck�

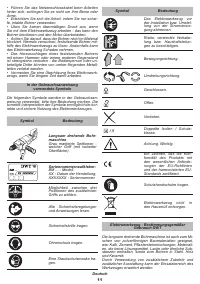

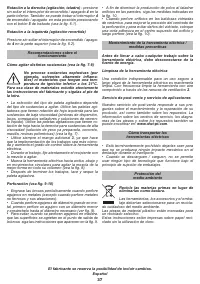

Mounting / dismounting of the drill chuck (see

fig. 4-5)

•

To mount the gear rim chuck

1

, carry out the op-

erations in consecutive stages as it is shown in fig

-

ure 4�

•

To dismount the gear rim chuck

1

, carry out the

operations in consecutive stages as it is shown in fig

-

ure 5�

Attention: keep in mind that in the pro-

cess of mounting / dismounting of the

drill chuck the screw 11 has a left-hand

thread.

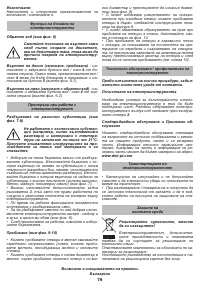

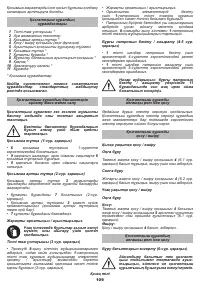

Initial operating

of the power tool

Always use the correct supply voltage: the power sup-

ply voltage must match the information quoted on the

power tool identification plate.

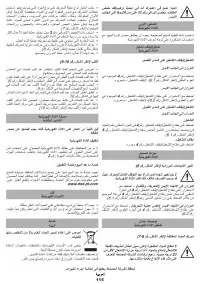

Switching the power

tool on / off

Short-term switching on / off

Rotation to the right

Press and hold the on / off switch

4

on the bottom (see

fig. 6.1), to switch off - release it.

Rotation to the left

Press and hold the on / off switch

4

on the top (see

fig. 6.2), to switch off - release it.

Long-term switching on / off

Rotation to the right

Switching on:

Press the on / off switch

4

on the bottom and lock it

in the position with locking button for on / off switch

5

(see fig. 6.1).

Switching off:

Push on / off switch

4

and release it�

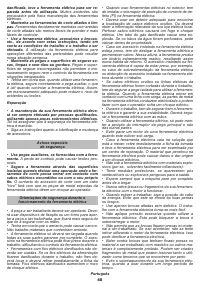

Design features

of the power tool

Changing the rotational directions (see fig. 6)

Change the direction of rotation only

after a full stop of the motor, acting oth-

erwise may cause damage to the power

tool.

Rotation to the right (stirring, drilling)

- press and

hold the on / off switch

4

on the bottom� Also on / off

switch

4

can be locked in this position by pressing with

lock-on button

5

(see fig. 6.1).

Rotation to the left (reverse stirring)

- press and

hold the on / off switch

4

on the top (see fig. 6.2).

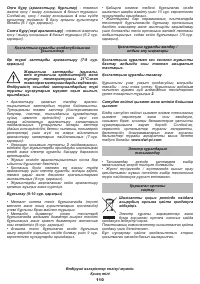

Recommendations

on the power tool operation

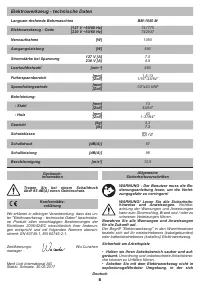

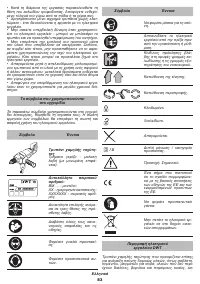

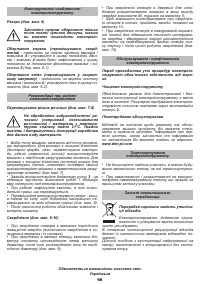

Stirring various substances (see fig. 7-8)

Do not process explosive substances

(for example, highly inflammable sol-

vents) and materials with ignition tem-

perature of lower than 21°С. Study the

manufacturer's instructions for such kind of mate-

rials carefully and stick to them.

•

The selection of stirring paddle type depends on the

type of substances stirred� Use stirring paddles with

left-hand blade spinning for low-viscosity substances

(dispersed paints, lacquers, sealing compounds, liquid

cement solution)� Use stirring paddles with right-hand

blade spinning for high-viscosity substances (ready-

made plastering solution, concrete, putty, polymeric

resins) (see fig. 7).

•

Always use additional handle

3

, as it makes the

implementation of works more convenient and in-

creases the degree of control over the power tool�

•

Fix the container with the mixture stirred carefully

during the work�

•

Move the power tool upward, downward and in cir-

cular movements to stir the mixture in the best manner

in its whole volume (see fig. 8).

• After finishing the works, wash and wipe stirring

paddle�

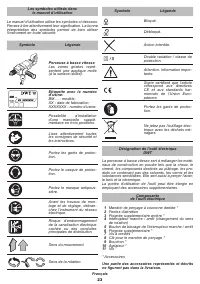

Drilling (see fig. 9-10)

•

Grease the drill bit regularly when drilling holes in

metals (except drilling non-ferrous metals and their al-

loys)�

• When drilling large diameter holes in metal, first drill

a hole with a smaller diameter and ream it till the nec-

essary diameter (see. fig. 9).

•

In order to avoid splitting of the surface at an exit

point of a drill bit when drilling holes in wood, follow the

instructions shown in figure 9.

•

In order to decrease dust production when drilling

holes in walls, take actions indicated in figure 10.

•

When drilling holes in glazed ceramic tiles, in order

to improve the drill centering accuracy and to save the