Шуруповерты Hitachi WH 9 DMR - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

English

8

CAUTION

Applying the impact driver for too long tightens the

screw too much and can break it.

Tightening a screw with the impact driver at an angle

to that screw can damage the head of the screw and

the proper force will not be transmitted to the screw.

Tighten with this impact driver lined up straight with

the screw.

OPERATIONAL CAUTIONS

1. Resting the unit after continuous work

After use for continuous bolt-tightening work, rest

the unit for 15 minutes or so when replacing the

battery. The temperature of the motor, switch, etc.,

will rise if the work is started again immediately after

battery replacement, eventually resulting in burnout.

NOTE

Do not touch the protector, as it gets very hot during

continuous work.

2. Cautions on use of the speed control switch

This switch has a built-in, electronic circuit which

steplessly varies the rotation speed. Consequently,

when the switch trigger is pulled only slightly (low

speed rotation) and the motor is stopped while

continuously driving in screws, the components of the

electronic circuit parts may overheat and be damaged.

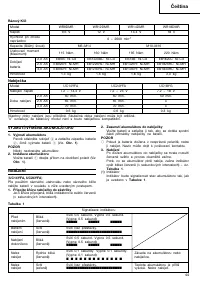

3. Use a tightening time suitable for the screw

The appropriate torque for a screw differs according to

the material and size of the screw, and the material

being screwed etc., so please use a tightening time

suitable for the screw. In particular, if a long tightening

time is used in the case of screws smaller than M8, there

is a danger of the screw breaking, so please confirm the

tightening time and the tightening torque beforehand.

4. Work at a tightening torque suitable for the bolt

under impact

The optimum tightening torque for nuts or bolts differs

with material and size of the nuts or bolts. An

excessively large tightening torque for a small bolt

may stretch or break the bolt. The tightening torque

increases in proportion to the operation time. Use

the correct operating time for the bolt.

5. Holding the tool

Hold the impact wrench firmly with both hands. In

this case hold the wrench in line with the bolt.

It is not necessary to push the wrench very hard.

Hold the wrench with a force just sufficient to

counteract the impact force.

6. Confirm the tightening torque

The following factors contribute to a reduction of the

tightening torque. So confirm the actual tightening

torque needed by screwing up some bolts before the

job with a hand torque wrench. Factors affecting the

tightening torque are as follows.

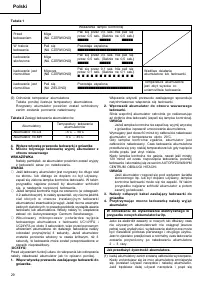

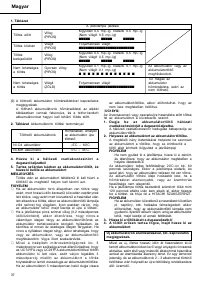

(1) Voltage

When the discharge margin is reached, voltage

decreases and tightening torque is lowered.

(2) Operating time

The tightening torque increases when the operating

time increases. But the tightening torque does not

increase above a certain value even if the tool is

driven for a long time.

(3) Diameter of bolt

The tightening torque differs with the diameter of the

bolt. Generally a larger diameter bolt requires larger

tightening torque.

(4) Tightening conditions

The tightening torque differs according to the torque

ratio; class, and length of bolts even when bolts with

the same size threads are used. The tightening torque

also differs according to the condition of the surface

of workpiece through which the bolts are to be

tightened. When the bolt and nut turn together, torque

is greatly reduced.

(5) Using optional parts (Impact wrench)

The tightening torque is reduced a little when an

extension bar, universal joint or a long socket is used.

(6) Clearance of the socket (Impact wrench)

A worn or deformed hex. or a square-holed socket

will not give an adequate tightness to the fitting

between the nut or anvil, consequently resulting in

loss of tightening torque.

Using an improper socket which does not match to

the bolt will result in an insufficient tightening torque.

MAINTENANCE AND INSPECTION

1. Inspecting the driver bit (Impact driver)

Using a broken bit or one with a worn out tip is

dangerous because the bit can slip. Replace it.

2. Inspecting the socket (Impact wrench)

A worn or deformed hex. or a square-holed socket will

not give an adequate tightness to the fitting between

the nut or anvil, consequently resulting in loss of

tightening torque. Pay attention to wear of a socket

holes periodically, and replace with a new one if needed.

3. Inspecting the mounting screws

Regularly inspect all mounting screws and ensure

that they are properly tightened. Should any of the

screws be loose, retighten them immediately. Failure

to do so may result in serious hazard.

4. Maintenance of the motor

The motor unit winding is the very “heart” of the

power tool.

Exercise due care to ensure the winding does not

become damaged and/or wet with oil or water.

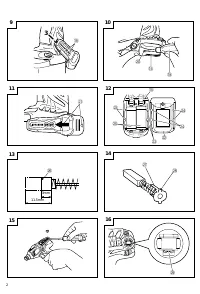

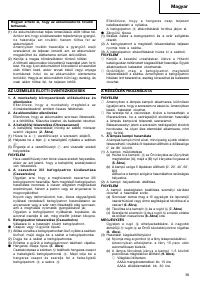

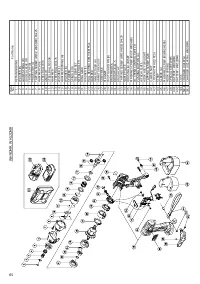

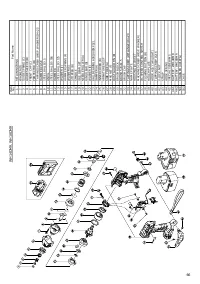

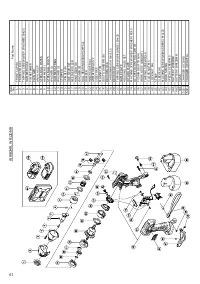

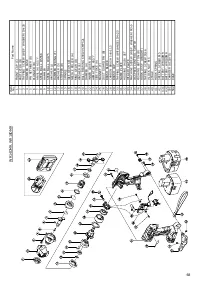

5. Inspecting the carbon brushes (Fig. 13)

The motor employs carbon brushes which are

consumable parts. Since and excessively worn carbon

brush can result in motor trouble, replace the carbon

brush with new ones when it becomes worn to or

near the “wear limit”

P

. In addition, always keep

carbon brushes clean and ensure that they slide freely

within the brush holders.

NOTE

When replacing the carbon brush with a new one, be

sure to use the Hitachi Carbon Brush Code No. 999054.

6. Replacing carbon brushes

Take out the carbon brush by first removing the

brush cap and then hooking the protrusion of the

carbon brush

R

with a slotted head screw driver,

etc., as shown in Fig. 15.

When installing the carbon brush, choose the direction

so that the nail of the carbon brush

Q

agrees with the

contact portion outside the brush tube

S

. Then push

it in with a finger as illustrated in Fig. 16. Lastly,

install the brush cap.