Пилы дисковые Graphite 58G488 - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

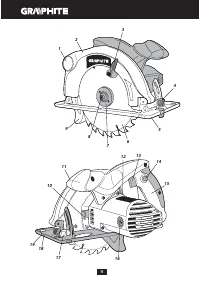

12

•

Insert parallel guide bar into two holes in the saw base

(5)

.

•

Set desired distance (use the scale).

•

use the parallel guide locking knob to fix the parallel guide

(4)

.

The parallel guide can also be used for cutting at angles ranging

from 0° to 45°.

Never put hand or fingers behind the working saw. When kick

back happens the saw can fall on the hand, it may be the cause

of heavy body injury.

MOVING THE LOWER GUARD

Lower guard

(9)

of cutting blade

(6)

is pushed away automatically as

the blade deepens into the material.

To remove it manually push the lower guard lever

(3)

.

DUST EXTRACTION

Circular saw is equipped with dust outlet

(1)

that allows for

extraction of sawdust produced when cutting.

OPERATION / SETTINGS

SWITCHING ON / SWITCHING OFF

The mains voltage must match the voltage on the rating plate of

the circular saw. Hold the saw with both hands when starting up,

because engine turning moment may cause uncontrolled turn of

the power tool.

Remember that rotating parts of the saw rotate for some time

after the tool has been switched off.

The saw is equipped with the switch lock button

(14)

that protects

against accidental starting.

Switching on:

•

Press the switch lock button

(14) (fig. B)

.

•

Press the switch button

(13)

.

Switching off:

•

Release pressure on the switch button

(13)

.

CUTTING

•

When starting operation always hold the saw firmly with both

hands by two handles.

•

Switch on the circular saw only when it is away from the material

that is to be cut.

•

Do not press the saw too hard. Pressure should be moderate and

continuous.

•

After the cut is finished allow the cutting blade to stop completely.

•

If the cutting is aborted before the task is completed, prior to

continuation start the saw and allow for idle operation. Wait until

the tool achieves its full rotational speed and then carefully drive

the cutting blade into the kerf in the processed material.

•

When cutting perpendicular to fibres of material (wood), fibres

tend to lift up and tear off (moving the saw slowly minimizes this

effect).

•

Ensure the lower guard reaches its extreme position.

•

Before starting to cut always ensure that cutting depth locking

lever and knob for base bevel adjustment are tightened firmly.

•

With the circular saw use only cutting blades with correct arbour

hole and outer diameter.

•

Processed material must be firmly fixed.

•

Place wider part of the saw base on the part of the material, which

is not cut off.

If the object is small, fix the processed material with F-clamps. If

the circular saw base does not move on the processed material,

but is lifted instead, there is danger of kick back.

Properly fixed processed material and firm hold of the tool ensure

full control over power tool operation. This allows to avoid risk of

body injury. Do not try to hold short pieces of material with your

hand.

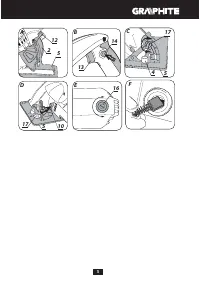

BEVEL CUTTING

•

Loosen the knob for base bevel adjustment

(17) (fig. C)

.

•

Use the scale to set the saw base to appropriate angle (from 0°

to 45°).

•

Tighten the knob for base bevel adjustment

(17)

.

Remember that for bevel cutting the risk of kick back is greater

(pinching of cutting blade more probable), therefore it is

particularly important that the saw base lies on the processed

material with its whole surface. Perform cutting with smooth move.

MAKING A CUT BY CUTTING INTO MATERIAL

Disconnect the saw from power supply before starting any

adjustments.

•

Set desired cutting depth that matches thickness of material

planned to be cut.

•

Tilt the saw so the front edge of the saw base lies on the cut

material and 0° marker for perpendicular cutting is in the line of

planned cutting.

•

When the saw is in the place to start cutting, lift the lower guard

(9)

with the lower guard lever

(3)

(cutting blade is lifted above the

material).

•

Switch the power tool on and wait until cutting blade reaches its

full rotational speed.

•

Gradually lower the saw and sink the cutting blade in material

(during this move front edge of the saw base should have contact

with surface of the material).

•

When the blade starts cutting release the lower guard.

•

When whole surface of the saw base rests on the material, move the

saw forward to proceed with cutting.

•

Never move the saw backwards when the blade is rotating, there

is danger of kick back.

•

Finish cutting in reverse order it was started, by turning the saw

around line of contact of the processed material and front edge

of the tool base.

•

Before removing blade from the material, allow it to stop after

switching the saw off.

•

Finish the process with reciprocating saw or hand saw when

necessary.

CUTTING OR CUTTING OFF LARGE PIECES OF MATERIAL

When cutting large boards of material support them to avoid

potential blade hitch (kick back) due to pinching the blade in

material kerf.

•

Support the panel or board close to the place of cutting.

•

Ensure the cutting blade settings guarantee that work bench or

support will not be damaged during cutting.

OPERATION AND MAINTENANCE

Unplug the power cord from the mains socket before commencing

any activities related to installation, adjustment, repair or

maintenance.

•

Keep the ventilation holes of the saw body pervious with no

deposition of dust. All adjustment parts of the saw should also be

clean. Clean them with brush when necessary. The most effective

cleaning is with the use of compressed air. Wear anti-splinter

goggles and protective mask always when using compressed air.

Do not clean ventilation holes by inserting sharp objects there, such

as screwdrivers and alike.

•

When cleaning never use petrol, solvents or detergents that could

damage plastic parts of the saw.

•

In case of excessive sparking on the motor commutator stop using

the power tool and deliver it to service workshop.

•

During normal operation cutting blade gets blunt after some

time. When it happens it is necessary to apply greater pressure

when moving the saw during cutting. When cutting blade is found

damaged, replace it immediately.

•

Cutting blade must always be sharp.

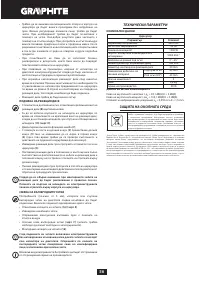

Характеристики

Остались вопросы?Не нашли свой ответ в руководстве или возникли другие проблемы? Задайте свой вопрос в форме ниже с подробным описанием вашей ситуации, чтобы другие люди и специалисты смогли дать на него ответ. Если вы знаете как решить проблему другого человека, пожалуйста, подскажите ему :)