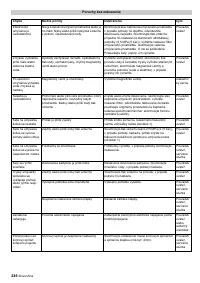

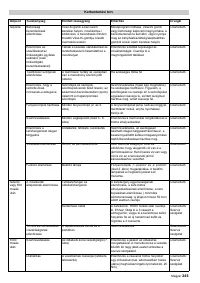

Мойки высокого давления Karcher HDS 13 24 PE Cage - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

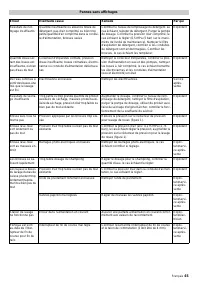

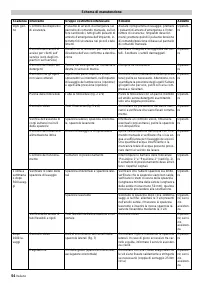

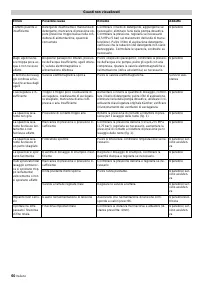

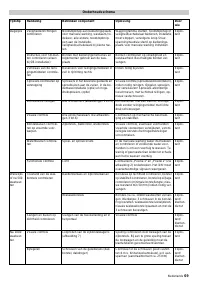

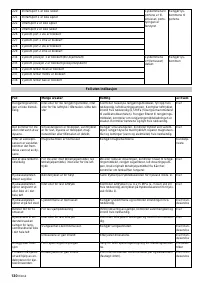

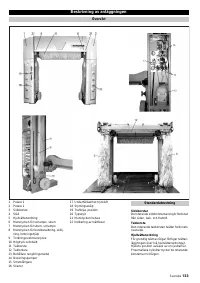

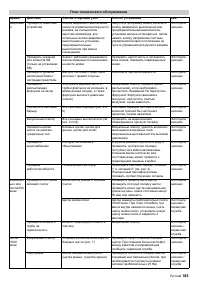

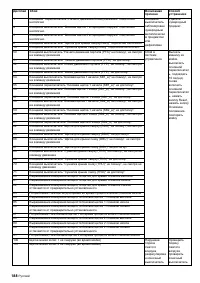

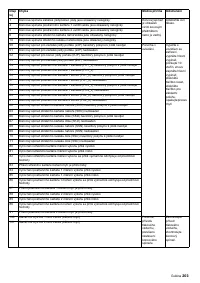

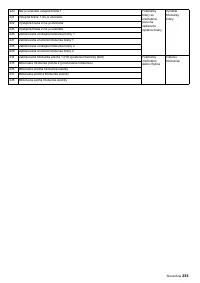

20

English

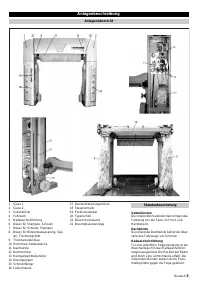

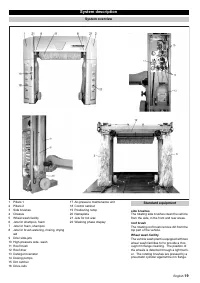

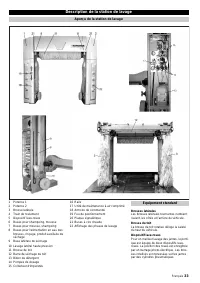

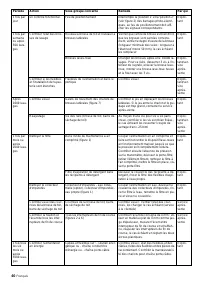

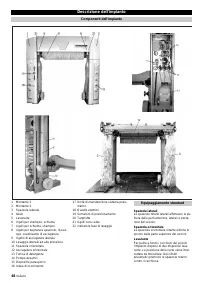

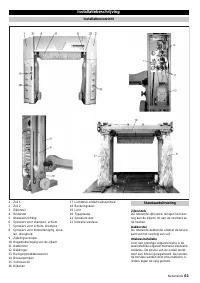

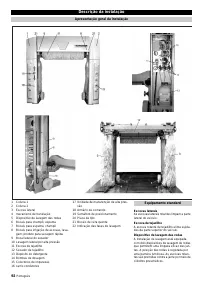

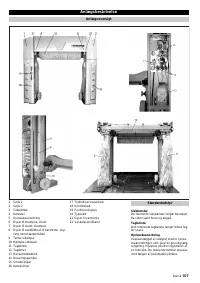

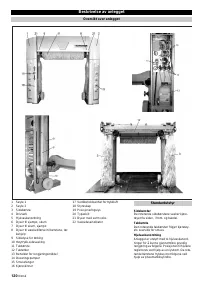

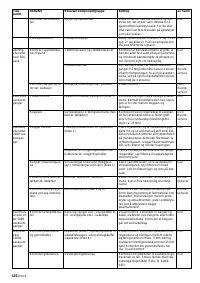

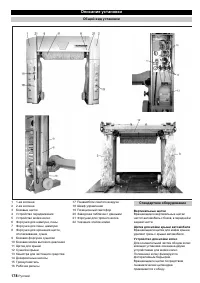

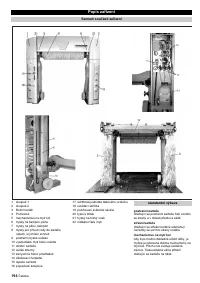

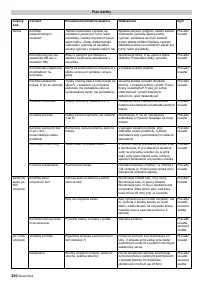

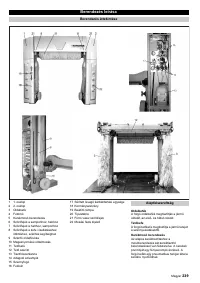

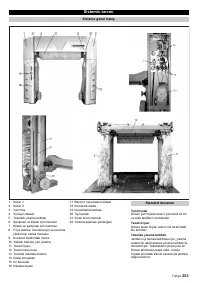

Shampoo from the jets for brush watering

mixed as detergent with water is sprayed on

the vehicle.

The foam wash sprays the vehicle with

foam before the wash.

The dirt catcher retains particles which

could block the jets.

The dosing pumps mixes the following de-

tergents and cleaning products with water:

– shampoo, foam, (DT 811)

– hot wax, (DT 829)

– drying aid, (DT 829).

The air needed for to blow-dry the vehicle

sides flows out of the drier jets.

The blow-dry beam is moved along the con-

tour of the vehicle. Built-in ventilators gen-

erate the necessary air flow to dry the

vehicle.

The vehicle positioning traffic light has two

functions:

– It is used to position the vehicle before

the wash.

– The drive-out direction is indicated after

the wash.

The light barriers detect:

– the position and contours of the vehicle

and

the position of the wheels.

The canisters for detergents and care-liquid

are installed in the pillar 2.

The important plant data on the nameplate.

The control cabinet for the plant is accomo-

dated in column 1.

The main switch for the plant is mounted on

the feed distributor. The feed distributor is

positioned outside the wash plant in the

plant room or another suitable location

nearby.

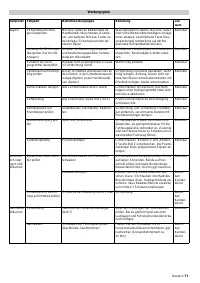

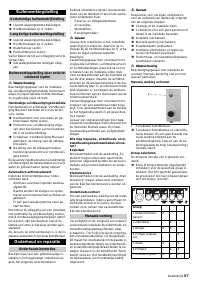

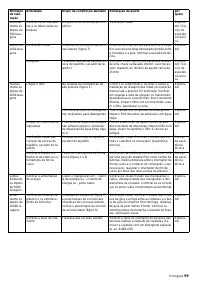

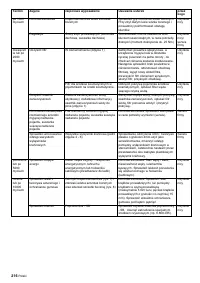

In the event of danger for persons, property

and animals, the plant must be switched off

immediately by pressing the emergency-

stop button. It is found

– at the operating device,

at the wash card reader.

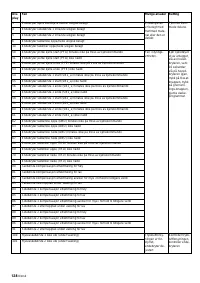

The vehicle wash plant is delivered with:

– with a control station for manual opera-

tion

– with a wash card/code reader (option)

– with a comfort operating point (option).

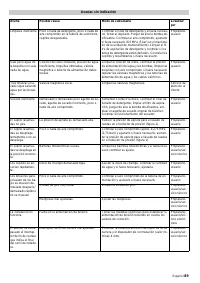

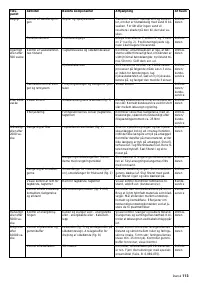

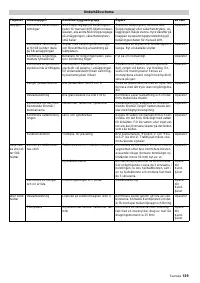

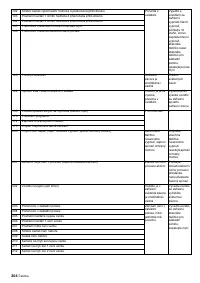

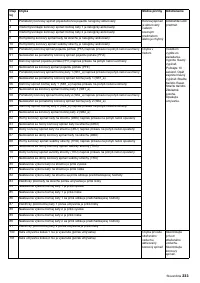

Also in the case of serious improper con-

duct by the washing customer, the plant

stays on the drive-rails.

The wash card or code reader is used for to

operate the wash plant with self-operation.

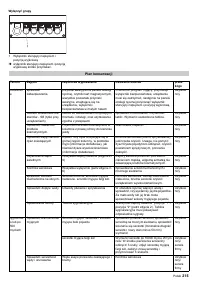

Note

The wash cards/codes required for opera-

tion are programmed for the specific plant.

enables the use of rainwater or recycled

water as a partial substitute for fresh water.

The optionally obtainable underfloor wash

facility enables the vehicle underside to be

washed. Hereby water is sprayed with high

pressure on the entire underside via two os-

cillating jet pipes.

The high-pressure wash removes excess

dirt from the surface of the vehicle. This

minimises the risk of grains of sand scratch-

ing the surface during the brush wash. Two

designs are available with operating pres-

sures of 1.6 MPa (16 bar) and 6 MPa (60

bar) respectively.

Hot water mixed with wax is sprayed onto

the vehicle out of the hot wax nozzles.

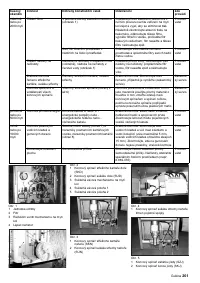

When there is danger of frost, the water is

blown out of the pipeline system. The wash

plant can be equipped with two anti-frost

devices:

– Anti-frost manual: The blow-out proce-

dure is enabled via the operator of the

plant.

Automatic anti-frost: The blow-out pro-

cedure is controlled via a thermostat.

The spurposts have the task to ensure a

middle alignment of the vehicle. They pre-

vent the vehicle being placed too far away

from the middle.

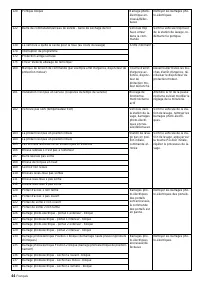

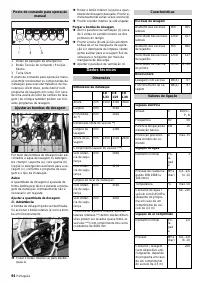

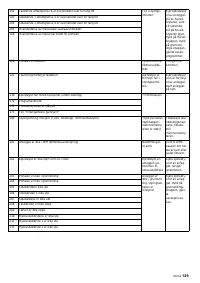

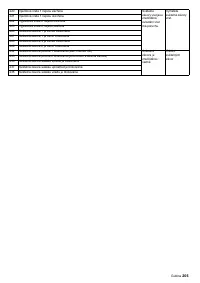

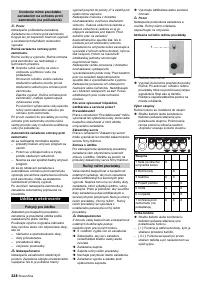

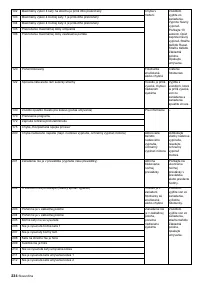

In the event of danger for persons, property

and animals, the plant must be switched off

immediately by pressing the emergency-

stop button. It is found

– at the wash card/code reader

– at the operating place for manual oper-

ator station

– at the entrance to the wash hall, íf an

operating point or wash card/code read-

er is located there.

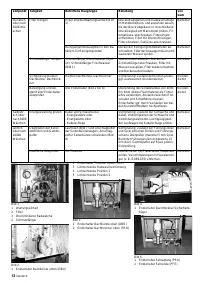

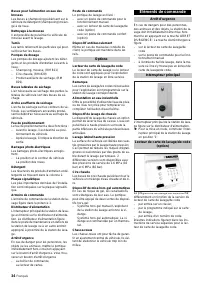

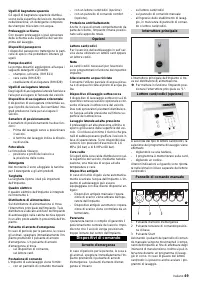

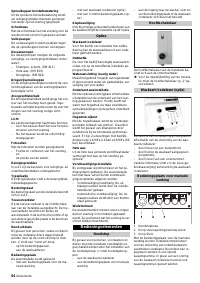

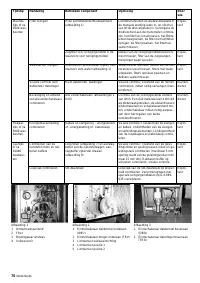

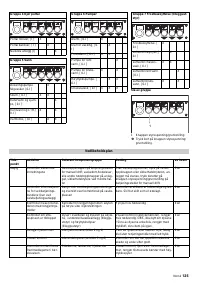

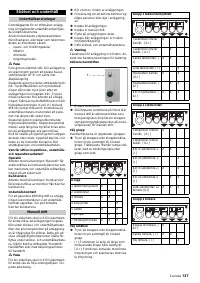

The main switch is located at the feeder.

Î

Set main switch at “1” to put the plant

into operation.

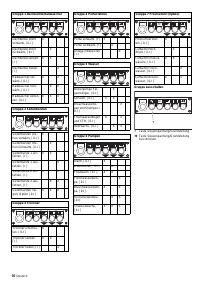

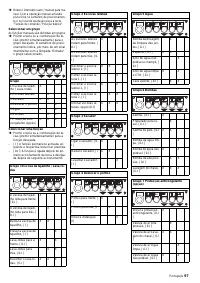

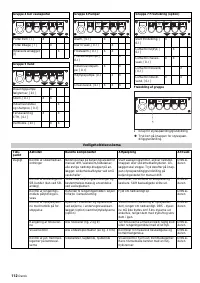

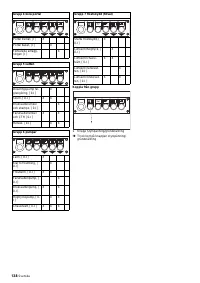

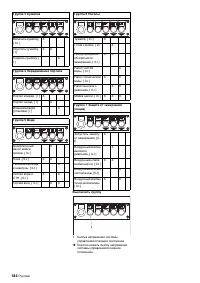

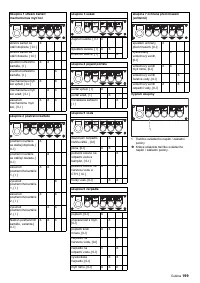

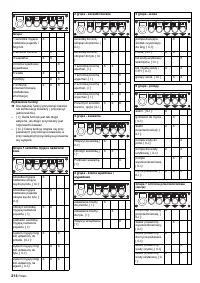

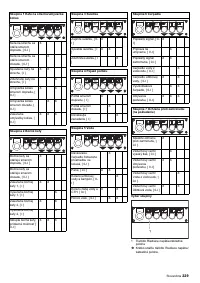

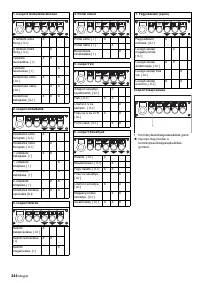

The choice of the wash programme de-

pending on the design of the wash card/

code reader

– by entering on a keyboard,

– through the programme stated on the

wash card,

– by entering a code number.

Further information is obtainable in the sep-

arate operating instructions on the wash

card/code reader.

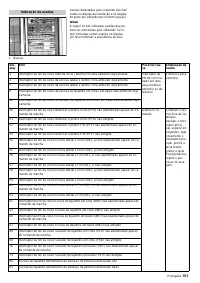

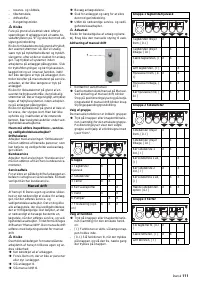

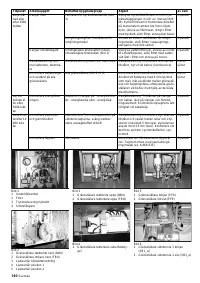

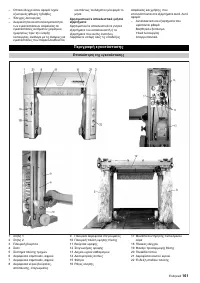

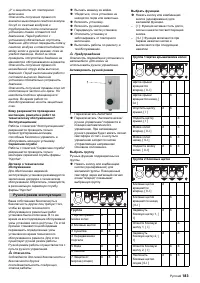

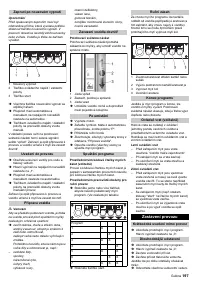

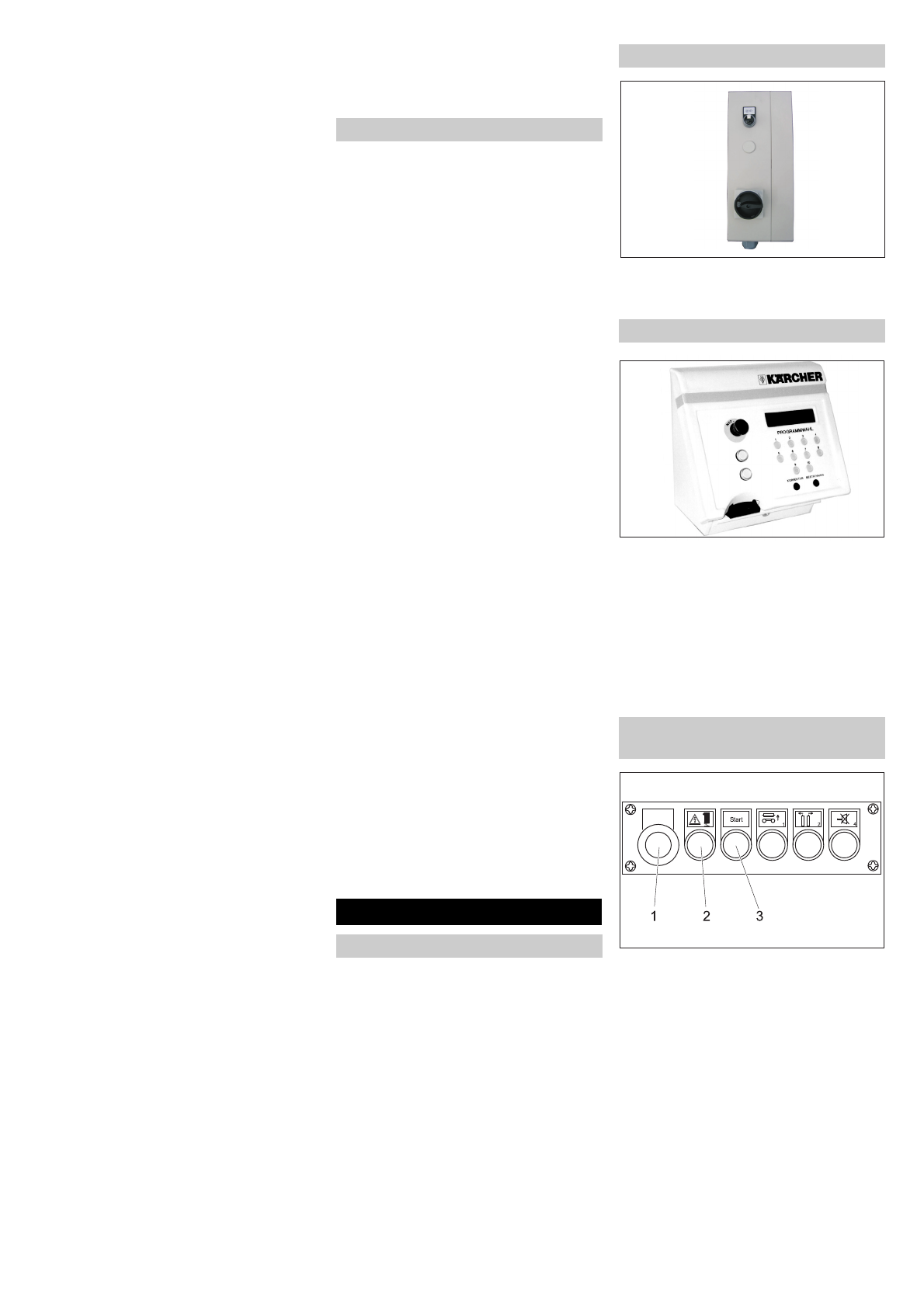

1 Emergency-stop button

2 Control supply voltage/normal position

button

3 Start key

The control station for manual operation

moves the plant components for mainte-

nance work to be done. This can also be

used to intervene when a wash programme

is in progress. In the case of a fault in the

wash card/code reader, the wash pro-

gramme can be also started.

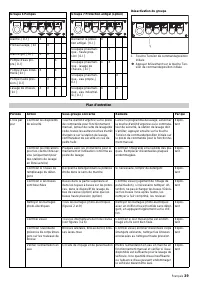

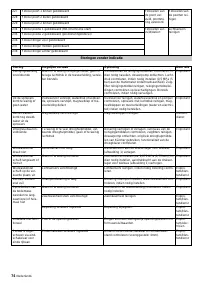

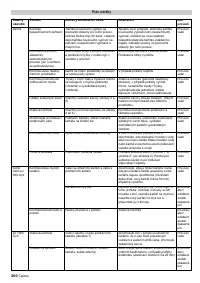

Jets for brush watering

Foam wash

Dirt catcher

Dosing pumps

Drier side-jets

Blow-dry beam

Positioning ramp

Light barriers

Detergent

Nameplate

Control cabinet

Feed distributor

Emergency-stop button

Control station

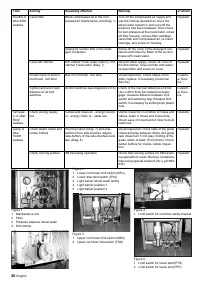

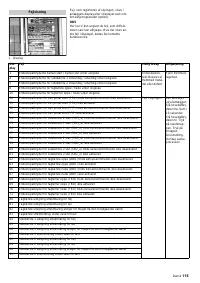

Safeguard against tipping over.

Options

Wash card/code reader

Processed water connection

Underfloor wash facility

High-pressure side

Hot wax

Anti-frost devices

Spurposts

Control elements

Emergency-stop

Main switch

Wash card/code reader (option)

Control station for manual opera-

tion