Мойки высокого давления IPC Portotecnica HPS DS2015T 44520 IDAC - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

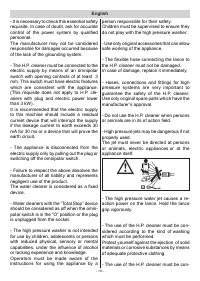

English

- 25 -

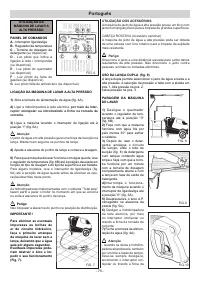

the ON/OFF switch in the “I” position.

6

) Start the cleaner and let it run until antifreeze comes out

through the lance.

7

) Suck up antifreeze with the detergent intake system too.

8

)

Disconnect the water cleaner from the mains electricity

supply via the omnipolar switch or by unplugging the plug from

the socket.

9

) For high pressure cleaners provided with water tank, the

detergent solution prepared as described in the point 3, must

be poured directly into the tank.

Warning

Anti-freeze may cause environmental pollution. Always follow

the instructions given on the pack. (Dispose of carefully.)

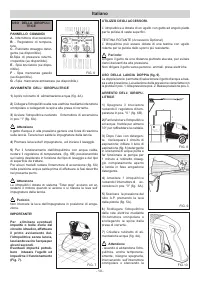

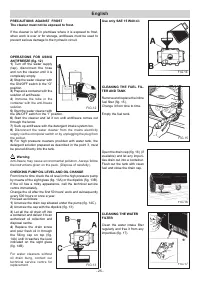

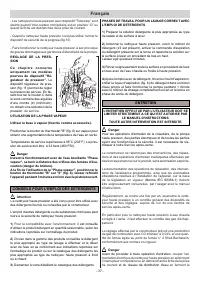

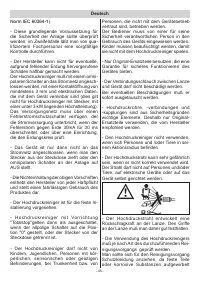

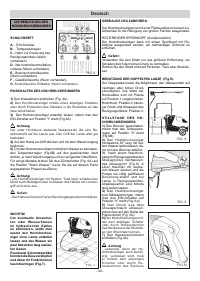

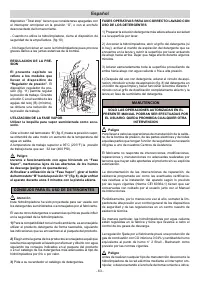

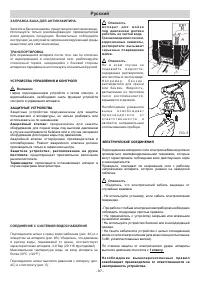

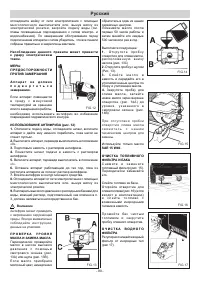

CHECKING PUMP OIL LEVEL AND OIL CHANGE

From time to time check the oil level in the high pressure pump

by means of the sight glass (fig. 13A) or the dipstick (fig. 13B).

If the oil has a milky appearance, call the technical service

centre immediately.

Change the oil after the first 50 hours' work and subsequently

every 500 hours or once a year.

Proceed as follows:

1

) Unscrew the drain cap situated under the pump (fig. 14C).

2

) Unscrew the cap with the dipstick (fig. 13).

FIG.12

FIG.13

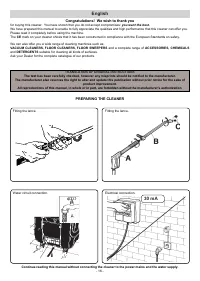

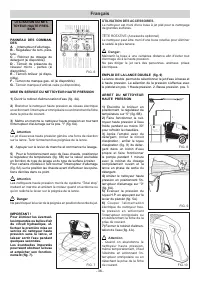

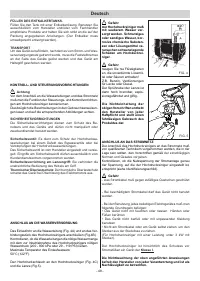

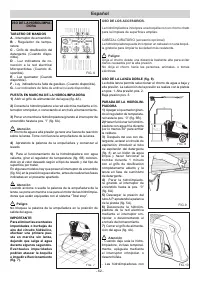

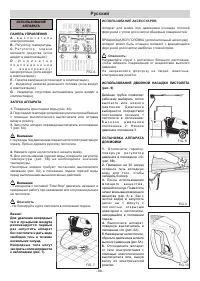

OPERATIONS FOR USING

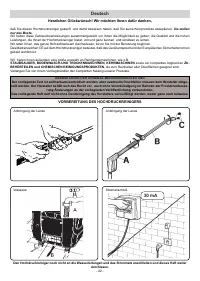

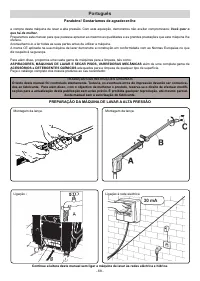

ANTIFREEZE (fig. 12)

1

) Turn off the water supply

(tap), disconnect the hose

and run the cleaner until it is

completely empty.

2

) Stop the water cleaner with

the ON/OFF switch in the “O”

position.

3

) Prepare a container with the

solution of antifreeze.

4

) Immerse the tube in the

container with the anti-freeze

solution.

5

) Start the water cleaner with

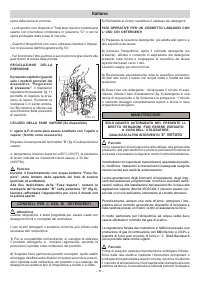

Use only SAE 15 W40 oil.

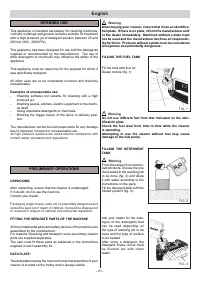

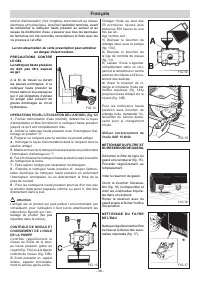

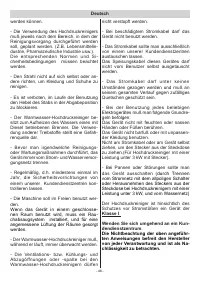

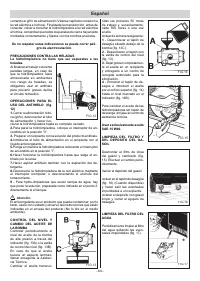

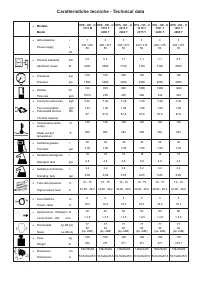

CLEANING THE FUEL FIL-

TER AND TANK

Remove and replace the inline

fuel filter (fig. 15).

Change it from time to time.

Empty the fuel tank.

Open the drain cap (fig. 16) (if

available) and let any impuri-

ties drain out into a container.

Flush out the tank with clean

fuel and close the drain cap.

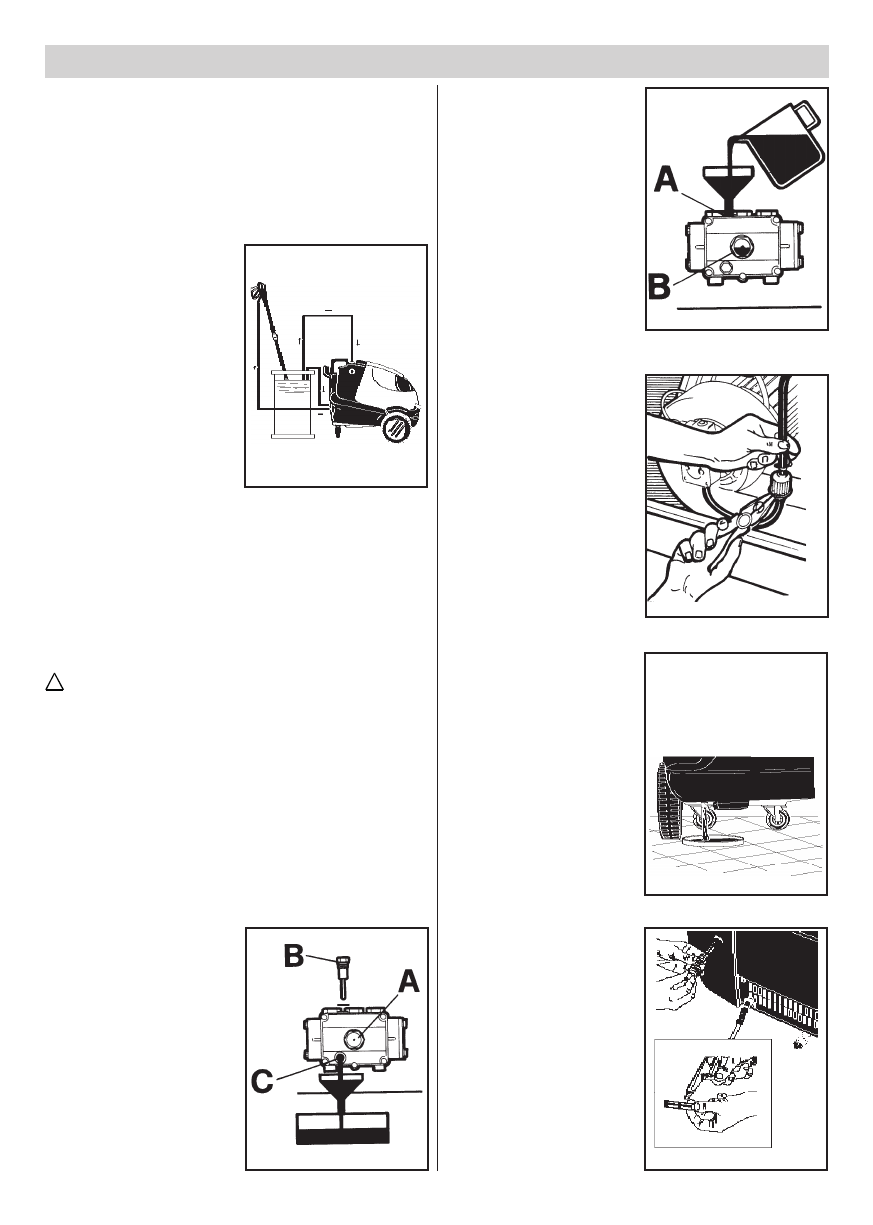

CLEANING THE WATER

FILTER

Clean the water intake filter

regularly and free it from any

impurities (fig. 17).

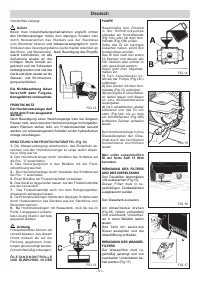

3

) Let all the oil drain off into

a container and deliver it to an

authorized oil collection and

disposal centre.

4

) Replace the drain screw

and pour fresh oil in through

the filling cap on top (fig.

14A) until it reaches the level

indicated on the sight glass

(fig. 14B).

For water cleaners without

oil drain bung, contact our

technical service centre for

replacement.

!

FIG.16

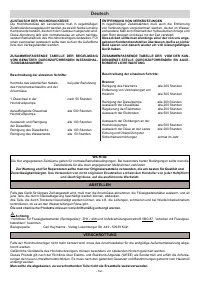

FIG.15

FIG.14

FIG.17

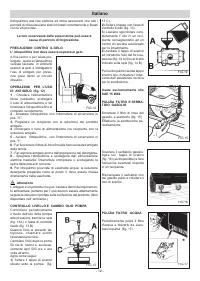

PRECAUTIONS AGAINST FROST

The cleaner must not be exposed to frost.

If the cleaner is left in premises where it is exposed to frost,

when work is over or for storage, antifreeze must be used to

prevent serious damage to the hydraulic circuit.

Содержание

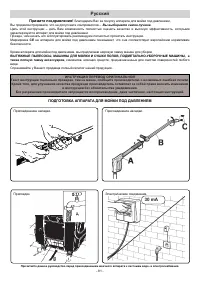

- 81 Русский; Примите поздравления!; СЕ; ПОДГОТОВКА АППАРАТА ДЛЯ МОЙКИ ПОД ДАВЛЕНИЕМ; ИНСТРУКЦИЯ ПЕРЕВОД ОРИГИНАЛЬНОЙ

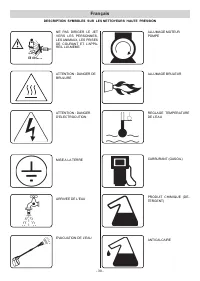

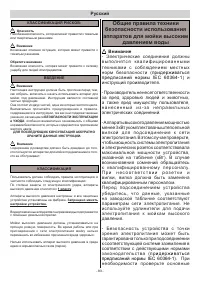

- 82 ОПИСАНИЕ СИМВОЛОВ НА АППАРАТЕ

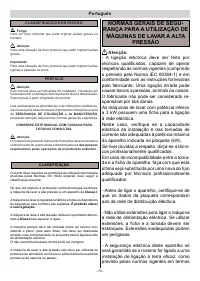

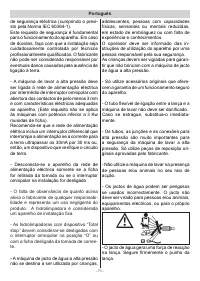

- 83 КЛАССИФИКАЦИЯ; Общие правила техники; Внимание; придерживаться; КЛАССИФИКАЦИЯ РИСКОВ:

- 86 ПОДГОТОВИТЕЛЬНЫЕ РАБОТЫ

- 88 Опасность

- 89 ОБСЛУЖИВАНИЕ

- 91 Для обслуживания и ремонта используйте

- 92 ВЫЯВЛЕНИЕ НЕИСПРАВНОСТЕЙ

- 93 НЕПОЛАДКА; ПРИЧИНА; УСТРАНЕНИЕ