Кондиционеры Daikin JEHCCU-CL1 - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

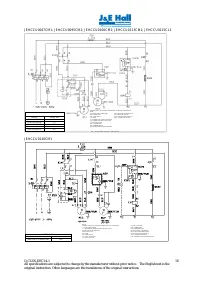

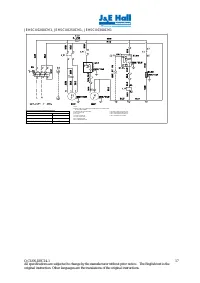

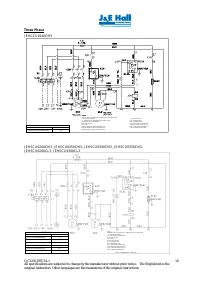

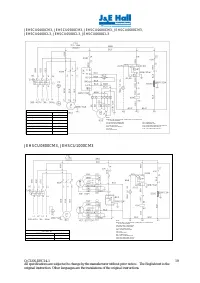

O-CU06-DEC14-1

All specifications are subjected to change by the manufacturer without prior notice.

The English text is the

original instruction. Other languages are the translations of the original instructions.

4

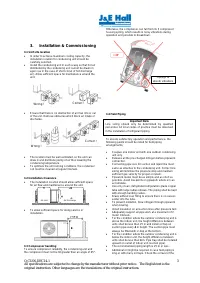

compressor to decide to add the oil after minimum 2

hours operation.

•

It is recommended as well to install the MOP (Maximum

Operation Pressure), expansion valve for medium

evaporating temperature units, if the working suction

pressure during start procedure especially after defrost

cycle, is out of the limit, as refer to the table provided.

Recommend compressor working pressure range

3.5 Pressure testing

•

Make sure that both service valves are closed when

running a pressure test on field piping, always use an

inert, dry gas such as Nitrogen

•

The pressure differential between the high and low side

shall not higher than below.

Compressor

Pressure differential

AE/AJ

19 barg

(275 psig)

MTZ/ZB*KQE

30 barg

(435 psig)

•

Test pressures shall be as shown follows.

Test pressure

High side

Low side

28 barg

(405 psig)

19 barg

(275 psig)

•

If there is pressure drop, check the leakage portion.

3.6 Leak detection

•

Make sure that all manual valves are open

•

Perform a leak test of the system using nitrogen mixed

with the refrigerant to be used

•

Do not use CFC for leak testing the condensing unit

which will be used with HFC refrigerants

•

The use of leak testing fluids is not recommended as

this may interact with the lubricants own additives

3.7 Vacuum - moisture removal

Air and moisture reduce service life and increase

condensing pressure causing abnormally high discharge

temperatures likely to destroy the oil’s lubricating properties.

The risk of acid formation is also increased by air and

moisture and copper plating can be generated in this way.

All these phenomena can cause mechanical and electrical

failure.

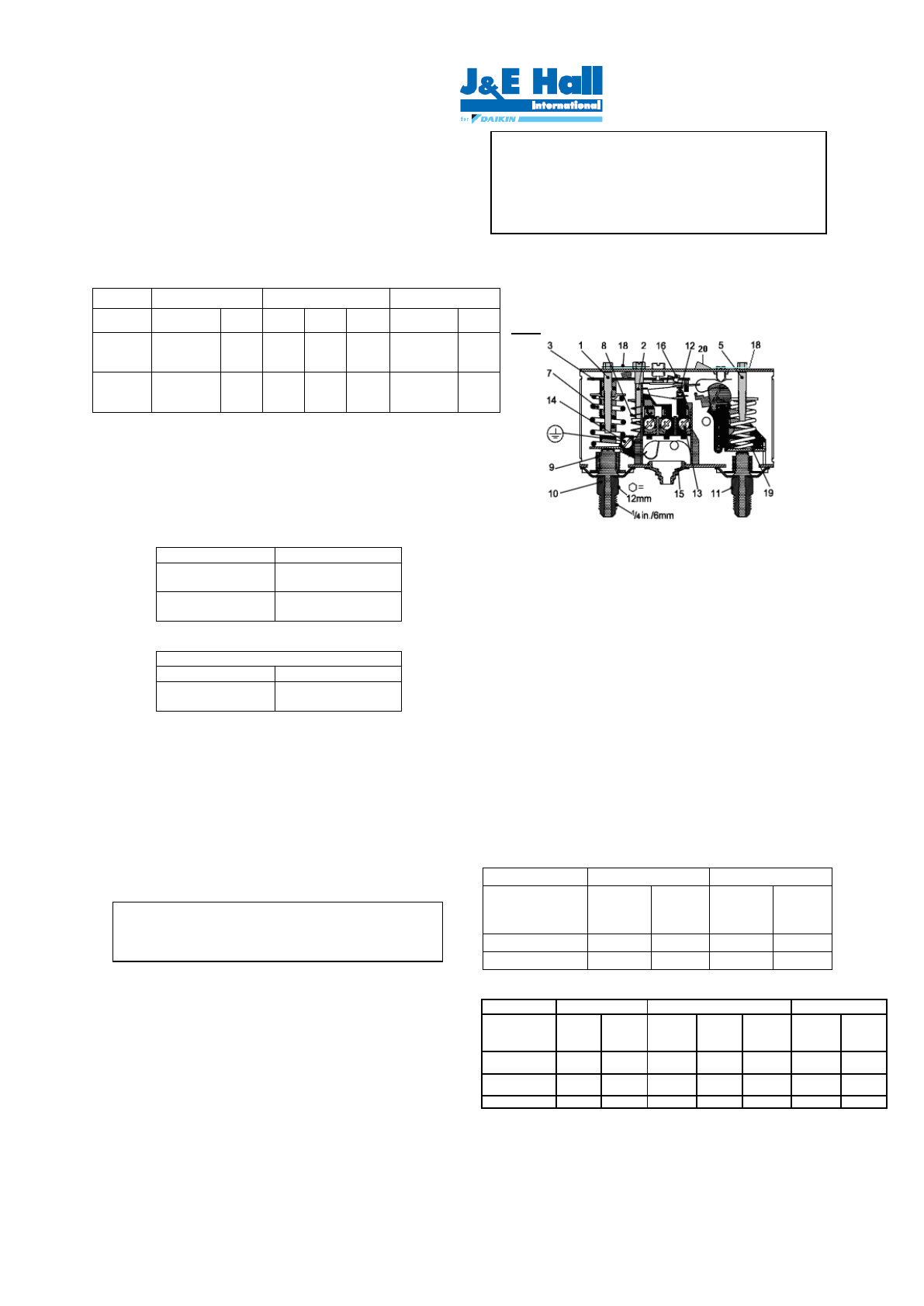

3.8 Safety pressure switch settings

The pressure switch fitted to condensing units with auto

reset for low pressure and manual reset for high pressure

are

NOT

factory preset.

1. Low pressure (LP) setting

spindle

2. Differential setting spindle, LP

3. Main arm

5. High pressure (HP) setting

spindle

7. Main spring

8. Differential spring

9. Bellows

10. LP connection

11. HP connection

12. Switch

13. Terminals

14. Earth terminal

15. Cable entry

16. Tumbler

18. Locking plate

19. Arm

20. Manual reset

button

High pressure safety (Manual reset)

The high pressure safety switch is required to protect the

compressor from working out of its envelope. The high

pressure switch shall set

equal or lower

than below values

depending on the type of refrigerant, application and the

ambient condition.

Model

AE/CAJ/TAJ

MTZ/ZB

Refrigerant

R404A/

R407A/

R407F

R134a

R404A/

R407A/

R407F

R134a

Cut Out (barg)

27.7

18

27.7

18

Cut Out (psig)

402

261

402

261

Model

AE/CAJ/TAJ

MTZ

ZB*KQE

Refrigerant

R404A/

R407A/

R407F

R134a

R404A

R134a

R407C

R404A/

R407A/

R407F

R134a

Application

M*

M*

M*

M*

M*

M*

M*

Cut out (barg)

1.5

0.5

1

0.6

1.4

2

0.6

Cut out (psig)

21.8

7.3

14.5

8.7

20.3

29

8.7

Compres s or Model

Refrigerant

R404A

R134a

R404A

R134a

R407C

R404A

R134a

W orking Pres s ure

Range High Side,

(barg)

13.2 - 27.7 6.7 - 15.8 13.2 - 27.7 7.9 - 22.6 12.5 - 29.4 7.14 - 27.6 6.6 - 22.6

W orking Pres s ure

Range Low Side,

(barg)

1.5 - 8.3

0.1 - 3.9

1.0 -7.2

0.6 - 4.7

1.4 - 6.6

1.98 - 7.14

0.6 - 3.8

Med Temp

MTZ

Med Temp

ZB*KQE

Med Temp

AE/CAJ/TAJ

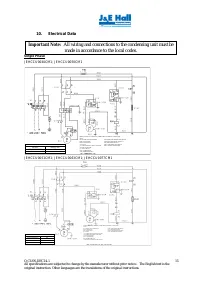

Important Note

Ensure that a good quality vacuum pump is used to pull

a minimum vacuum of -0.1 barg (250 microns) or less.

Ensure that no pressure increase during 1 hour or more

after stop vacuuming. If pressure increase, there is

moisture or leakage along the pipeline.

Important Note

Moisture prevents proper functioning of the compressor

and the refrigeration system

flare

Compressor

Model

Med Temp

AE/CAJ/TAJ

Med Temp

MTZ

Med Temp

ZB*KQE

Refrigerant

R404A/R407A/

R407F

R134a

R404A

R134a

R407C

R404A/R407A/

R407F

R134a

Working

Pressure

Range High

Side (barg)

13.2 – 27.7

6.7 –

15.8

13.2 –

27.7

7.9 –

22.6

12.5 –

29.4

7.14 – 27.6

6.6 –

22.6

Working

Pressure

Range Low

Side, (barg)

1.5 – 8.3

0.1 –

3.9

1.0 –

7.2

0.6 –

4.7

1.4 –

6.6

1.98 – 7.14

0.6 –

3.8