Гайковерты Bosch GDR 12V-110 - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

16

| English

1 609 92A 29D | (20.7.16)

Bosch Power Tools

after an impact duration of 6 – 10 seconds. After this dura-

tion, the tightening torque is increased only minimally.

The impact duration is to be determined for each required

tightening torque. The actually achieved tightening torque is

always to be checked with a torque wrench.

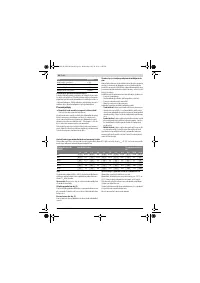

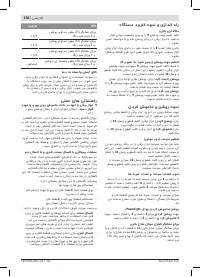

Screw Applications with Hard, Spring-loaded or Soft Seat

A test in which the achieved torques in an impact series are

measured and transferred to a diagram will produce the curve

of a torque characteristic. The height of the curve corre-

sponds with the maximum reachable torque, and the steep-

ness indicates the duration in which this is achieved.

A torque gradient depends on the following factors:

– Strength properties of the screws/nuts

– Type of backing (washer, disc spring, seal)

– Strength properties of the material being screwed/bolted

together

– Lubrication conditions at the screw/bolt connection

The following application cases result accordingly:

– A

hard seat

is given for metal-to-metal screw applications

with the use of washers. After a relatively short impact du-

ration, the maximum torque is reached (steep characteris-

tic curve). Unnecessary long impact duration only causes

damage to the machine.

– A

spring-loaded seat

is given for metal-to-metal screw ap-

plications, however with the use of spring washers, disc

springs, studs or screws / nuts with conical seat as well as

when using extensions.

– A

soft seat

is given for screw applications, e. g., metal on

wood or when using lead washers or fibre washers as back-

ing.

For a spring-loaded seat as well as for a soft seat, the maxi-

mum tightening torque is lower than for a hard seat. Also, a

clearly longer impact duration is required.

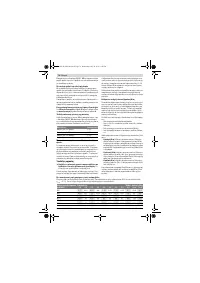

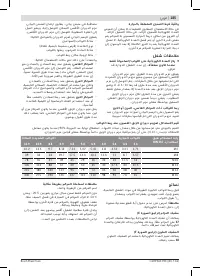

Reference Values for Maximum Screw/Bolt Tightening Torques

Calculated from the tensional cross-section; utilization of the yield point 90 % (with friction coefficient μ

total

= 0.12). As a control

measure, always check the tightening torque with a torque wrench.

Tips

Before screwing larger, longer screws into hard materials, it is

advisable to predrill a pilot hole with the core diameter of the

thread to approx.

2

/

3

of the screw length.

Note:

Pay attention that no metal particles enter the power

tool.

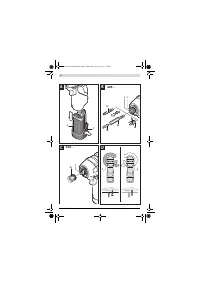

Belt Clip (see figure E)

With the belt clip

17

, the machine can be hung onto a belt. The

user has both hands free and the machine is always at hand.

Colour clip (see figure F)

You can use the colour clip

18

to individually label the power

tool.

Recommendations for Optimal Handling of the Battery

Protect the battery against moisture and water.

Store the battery only within a temperature range between

– 20 ° C and 50 ° C. As an example, do not leave the battery in

the car in summer.

Occasionally clean the venting slots of the battery using a soft,

clean and dry brush.

A significantly reduced working period after charging indi-

cates that the battery is used and must be replaced.

Observe the notes for disposal.

Maintenance and Service

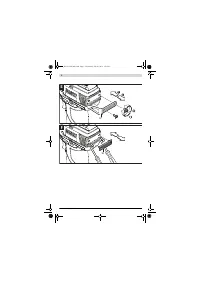

Maintenance and Cleaning

Before any work on the machine itself (e. g. mainte-

nance, tool change, etc.) as well as during transport

and storage, remove the battery from the power tool.

There is danger of injury when unintentionally actuating

the On/Off switch.

For safe and proper working, always keep the machine

and ventilation slots clean.

After-sales Service and Application Service

Our after-sales service responds to your questions concern-

ing maintenance and repair of your product as well as spare

parts. Exploded views and information on spare parts can al-

so be found under:

www.bosch-pt.com

Bosch’s application service team will gladly answer questions

concerning our products and their accessories.

In all correspondence and spare parts orders, please always

include the 10-digit article number given on the nameplate of

the product.

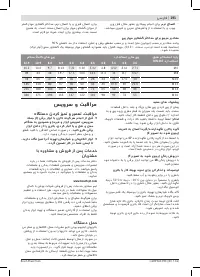

Property Classes accord-

ing to DIN 267

Standard Screws/Bolts

High-strength Bolts

3.6

4.6

5.6

4.8

6.6

5.8

6.8

6.9

8.8

10.9

12.9

M 6

2.71

3.61

4.52

4.8

5.42

6.02

7.22

8.13

9.7

13.6

16.2

M 8

6.57

8.7

11

11.6

13.1

14.6

17.5

19.7

23

33

39

M 10

13

17.5

22

23

26

29

35

39

47

65

78

M 12

22.6

30

37.6

40

45

50

60

67

80

113

135

M 14

36

48

60

65

72

79

95

107

130

180

215

M 16

55

73

92

98

110

122

147

165

196

275

330

OBJ_BUCH-2928-001.book Page 16 Wednesday, July 20, 2016 1:58 PM

Содержание

- 108 Описание продукта и услуг; Применение по назначению

- 109 Технические данные; Сборка

- 110 Замена рабочего инструмента; Работа с инструментом; Принцип действия

- 111 Указания по применению

- 112 Техобслуживание и сервис; Техобслуживание и очистка; Транспортировка

- 113 Утилизация; Українська; Вказівки з техніки безпеки; Загальні застереження для електроприладів

Характеристики

Остались вопросы?Не нашли свой ответ в руководстве или возникли другие проблемы? Задайте свой вопрос в форме ниже с подробным описанием вашей ситуации, чтобы другие люди и специалисты смогли дать на него ответ. Если вы знаете как решить проблему другого человека, пожалуйста, подскажите ему :)