Дрели Bosch GDB 350 WE - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

English |

21

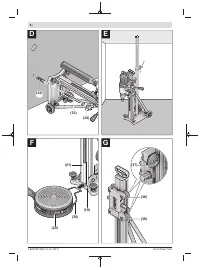

Removing the core bit

u

Wear protective gloves when changing the core bit.

The core bit may become hot when the power tool is op-

erated for extended periods of time.

Detach the core bit

(6)

using an open-ended spanner (width

across flats 41 mm). When doing so, hold a second open-

ended spanner (width across flats 32 mm) on the two flats

of the drill spindle

(7)

to provide counterforce.

The easy-release element

(8)

makes it easier to remove the

core bit

(6)

.

Connecting the water cooling system

If wet core bits are not kept sufficiently cool during drilling,

the diamond segments can become damaged or the core bit

can get stuck in the drill hole. It is therefore important to en-

sure a sufficient feed of water when wet-drilling.

When expanding an existing hole, this must be sealed care-

fully to allow the core bit to be sufficiently cooled.

u

Connected hoses, shut-off valves or accessories must

not interfere with drilling.

Close the water cutoff valve

(5)

. Connect a water supply line

to the valve adapter

(4)

. The water supply line can be

provided from a mobile pressurised water tank (accessory)

or a stationary water connection.

You will need a water collection ring and a wet/dry extractor

(both accessories) to collect the water that escapes from the

drill hole during wet drilling.

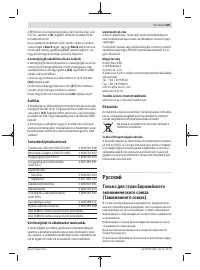

Fitting a water collection ring for water extraction

(see figure F)

The water collection ring (see "Accessories/replacement

parts", page 23) is intended for use with the drill stand for

diamond drills

GCR 350

and the diamond drill

GDB 350 WE

.

Cut an opening for the required drilling diameter in the seal-

ing cover.

Push the tension spring

(35)

as far as possible into the gap

between the base plate

(19)

and drill column

(21)

. Make

sure that the angled section of the tension spring is facing

downwards.

Put the water collection ring in position and place the ten-

sion spring on the contact points on the water collection

ring. (The lugs on the ends of the tension spring are used to

pull the tension spring upwards.)

The tensioning force of the spring will press the water collec-

tion ring with its seal onto the surface. Together with the va-

cuum of the wet/dry extractor, this will prevent water from

escaping.

The water collection ring can be turned inside its tension ring

in order to put the extraction outlet in the necessary position

(e.g. to optimise the water drainage when drilling holes hori-

zontally). To do so, open the lock of the tension ring on the

water collection ring, turn the water collection ring as re-

quired and close the lock again.

Operation

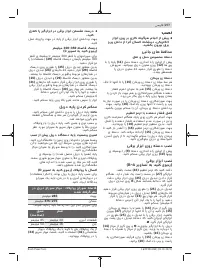

Changing the drilling angle

u

Pull the plug out of the socket before carrying out any

work on the power tool.

u

Always retighten all the screws after making adjust-

ments to the drill stand.

Loosen the cap nut

(17)

using the star handle

(15)

.

Set the drill stand to the required drilling angle using the

drilling angle scale

(13)

. Refer to the arrow next to the cap

nut

(17)

to set it exactly.

Tighten the cap nut

(17)

hand-tight using the star

handle

(15)

.

u

The drill stand must not be inserted until the cap nut

(17) of the angle adjustment has been retightened.

Starting operation

u

Pay attention to the mains voltage.

The voltage of the

power source must match the voltage specified on the

rating plate of the power tool.

u

Seek advice from the responsible structural engineer,

architect or construction supervisor regarding

planned drill holes before starting work. Do not penet-

rate any reinforcements unless you have authorisa-

tion from a structural engineer.

u

When drilling holes that penetrate walls or ceilings, al-

ways check the area concerned for obstacles. Close

off the work site and prevent the drill core from falling

by means of formwork.

Function test of the portable residual current device

(PRCD)

Before starting work, always check that the portable residual

current device (PRCD)

(1)

is functioning correctly:

– Press the

TEST

button on the residual current device

(PRCD). The red indicator light will switch off.

– Press the

RESET

button. It must now be possible to

switch the power tool on.

If the red indicator light does not switch off when you press

the

TEST

button or it switches off repeatedly when the

power tool is switched on, you must have the power tool

checked by an authorised

Bosch

after-sales service centre.

u

The power tool must not be used if the portable resid-

ual current device (PRCD) is defective.

Switching on

Press the

RESET

button on the portable residual current

device (PRCD)

(1)

.

Set the water cutoff valve

(5)

to flow.

To switch on the power tool, rock the on/off switch

(2)

to

position

1

.

Switching off

To switch off the power tool, rock the on/off switch

(2)

to

position

0

.

Bosch Power Tools

1 609 92A 4NK | (21.01.2021)

Характеристики

Остались вопросы?Не нашли свой ответ в руководстве или возникли другие проблемы? Задайте свой вопрос в форме ниже с подробным описанием вашей ситуации, чтобы другие люди и специалисты смогли дать на него ответ. Если вы знаете как решить проблему другого человека, пожалуйста, подскажите ему :)