Шуруповерты GRAPHITE Energy+ 58g006 - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

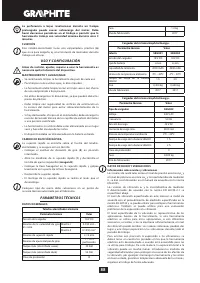

13

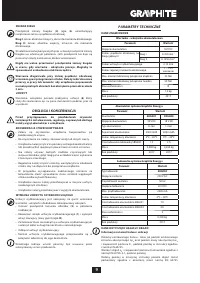

M E A N I N G O F S YM B O L S

CAUTION

WARNING

ASSEMBLY / SET TINGS

INFORMATION

PREPARATION FOR OPERATION

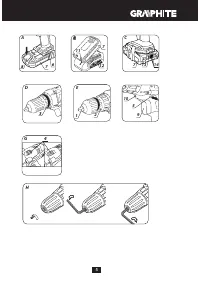

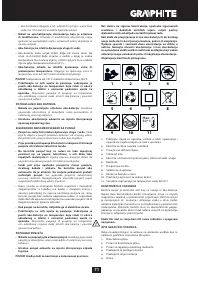

REMOVING AND INSERTING THE BAT TERY

•

Set the direction selector switch (

5

) in middle position.

•

Push the batter y lock button (

8

) and slide out the batter y (

7

)

(

fig. A

).

•

Inser t charged batter y (

7

) into the handle holder, you should

hear when the batter y lock button (

8

) snaps.

BAT TERY CHARGING

The device is supplied with par tially charged batter y. The batter y

should be charged in ambient temperature between 4°C and

40°C. New batter y, or one that has not been used for a long

time, will reach full efficiency after approximately 3 to 5 charge/

discharge cycles.

•

Remove the batter y (

7

) from the device (

fig. A

).

•

Connect the charger to mains socket (230 V AC).

•

Slide the batter y (

7

) into the charger (

12

) (

fig. B

). Ensure the

batter y is properly fitted (pushed to the end).

When the charger is connected to a mains socket (

230 V AC

), the

green diode (

11

) on the charger turns on to indicate connected

supply.

When the batter y (

7

) is placed in the charger (

12

), the red diode

(

11

) on the charger turns on to indicate that the charging is in

progress.

Simultaneously, green diodes (

14

) of the batter y level indication

are flashing in different configurations, see description below.

• All diodes are flashing

- batter y is empty and requires

charging.

• 2 diodes are flashing

- the batter y is par tially discharged.

• 1 diode is flashing

- the batter y level is high.

Once the batter y is charged, the diode (

11

) on the charger lights

green, and all batter y level diodes (

14

) light continuously. After

some time (approx. 15 s) batter y level indication diodes (

14

) turn

off.

Do not charge the batter y for more than 8 hours. Exceeding

this time limit may cause damage to batter y cells. The charger

will not turn off automatically when the batter y is full. Green

diode on the charger will remain on. Batter y level indication

diodes turn off after some time. Disconnect power supply

before removing the batter y from the charger socket. Avoid

consecutive shor t chargings. Do not charge the batter y after

shor t use of the tool. Significant decrease of the period

between chargings indicates the batter y is used up and should

be replaced.

Batteries heat up when charging. Do not operate just

after charging – wait for the batter y to cool down to room

temperature. It will prevent batter y damage.

BAT TERY LE VEL INDIC ATION

The batter y is equipped with signalisation of the batter y level (3

LED diodes) (

14

). To check batter y level status, press the button

for batter y level indication (

13

) (

fig. C

). When all diodes are lit,

the batter y level is high. When 2 diodes are on, the batter y is

par tially discharged. When only one diode is lit, the batter y is

discharged and must be recharged.

S P I N D L E B R A K E

Drill is equipped with electronic brake that stops the spindle

immediately after the switch button (

9

) is released. The brake

ensures precision when screwing or drilling and prevents free

spindle rotation after switching off.

OPERATION / SETTINGS

S W I TC H I N G O N / S W I TC H I N G O F F

Switching on

– press the switch button (

9

).

Switching off

– release the switch button (

9

).

Each time the switch button (

9

) is pressed, the LED diode (

10

)

lights up to illuminate the workplace.

ROTATIONAL SPEED CONTROL

Increase or reduce pressure on the switch button (

9

) to adjust

drilling or driving speed while operating. Speed adjustment

allows for a soft star t, which prevents dill slipping when drilling

holes in gypsum or glaze, and allows for operation control when

driving screws in and out.

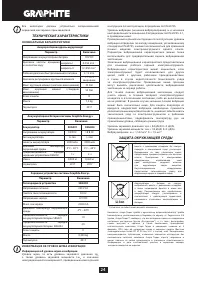

OV E R LOA D C LU TC H

Set the torque adjustment ring (

3

) in appropriate position

to permanently set overload clutch to defined torque value.

When the set torque is reached, overload clutch disconnects

automatically. It prevents from driving screws too deep or

damaging the drill.

TO RQUE ADJUSTMENT

•

Different screws and materials require different torque to be

applied.

•

The bigger the number corresponding to given position, the

bigger is the torque (

fig. D

).

•

Set the torque adjustment ring (

3

) to appropriate torque value.

•

Always star t operation with low torque.

•

Increase the torque gradually until obtaining desired results.

•

Use higher settings to undo screws.

•

When drilling, choose setting marked with the drill symbol.

The torque is the greatest with this setting.

•

Knowledge how to choose appropriate torque setting comes

with practice.

Setting the torque adjustment ring in the drilling position

deactivates the overload clutch.

WO R K I N G TO O L I N S TA L L AT I O N

•

Set the direction selector switch (

5

) in the middle position.

•

By turning the ring of the quick release chuck (

2

) counter

clockwise (see mark on the ring) you can spread jaws enough

to inser t drill or driver bit (

fig. E

).

•

To fix the working tool, turn the ring of the quick release chuck

(

2

) clockwise and tighten.

Deinstallation of the tool is similar to installation, only the

sequence of actions is reversed.

Make sure the tool position is correct when installing drill or

driver bit in the quick release chuck. Use additional magnetic

adapter as an extension when using shor t driver bits.

RIGHT-LEFT DIREC TION OF ROTATION

Choose direction of spindle rotation with the direction selector

switch (

5

) (

fig. F

).

Clockwise rotation

– set the switch (

5

) to the extreme left

position.