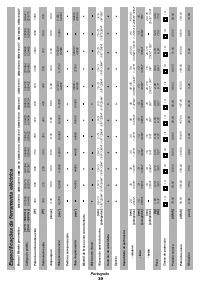

Шуруповерты DWT SBM-1050 DT 5.1.24 - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

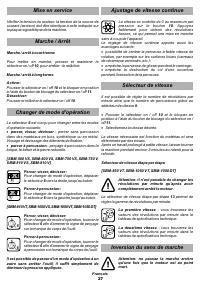

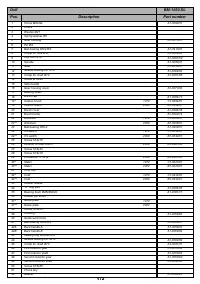

English

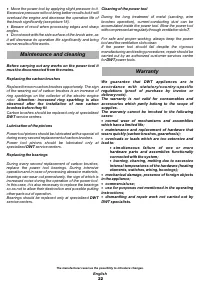

Avoid overheating your electric tool, when using it for

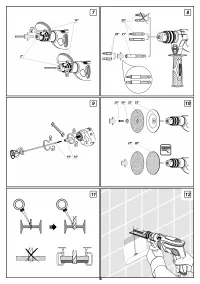

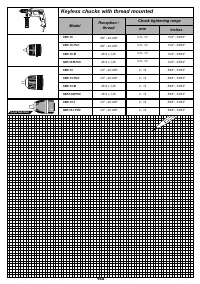

Lock keyless chuck

1

or

12

on the power tool spindle,

a long time.

having tightened screw

33

.

Attention: screw

33

has a

left-hand thread

. Prior to that, move the cams of

keyless chuck

1

or

12

apart at the distance allowing

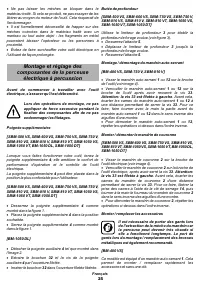

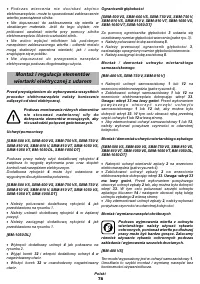

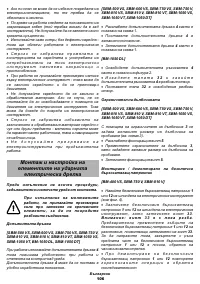

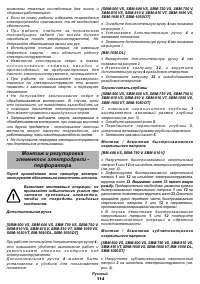

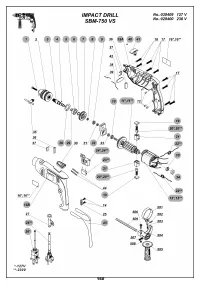

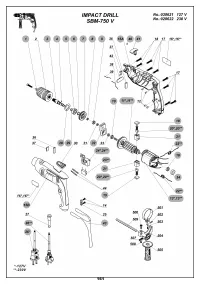

Mounting and adjustment of the

screw

33

to be tightened. To do that, rotate the front part

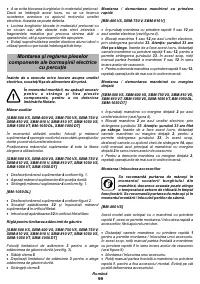

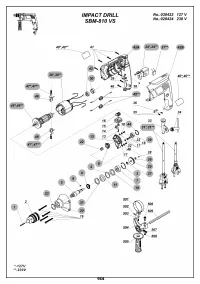

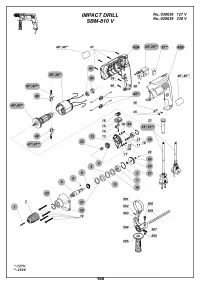

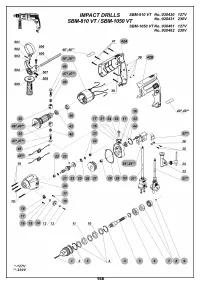

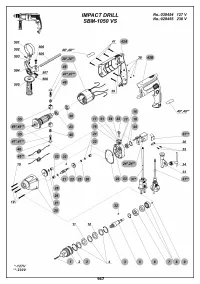

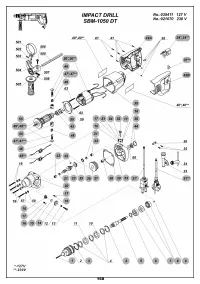

impact electric drill components

of keyless chuck

1

or

12

counter-clockwise with your

hand.

When keyless chuck

1

or

12

is being dismounted,

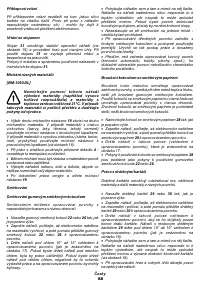

Before carrying out any works on the power tool it

repeat the aforementioned operations in reverse order.

must be disconnected from the mains.

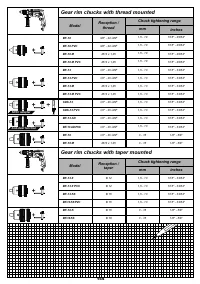

Mounting / dismounting of the gear rim chuck

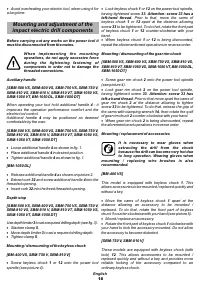

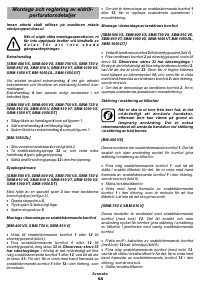

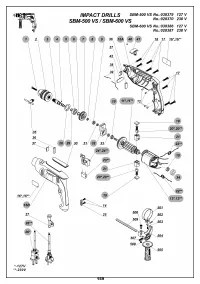

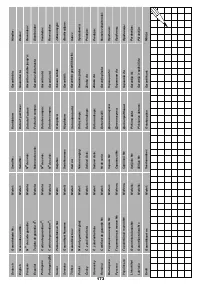

W h e n i m p l e m e n t i n g t h e m o u n t i n g

operations, do not apply excessive force

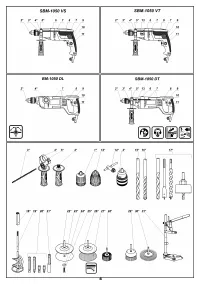

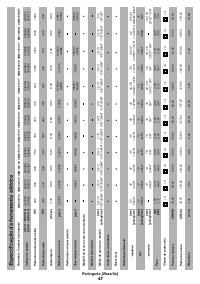

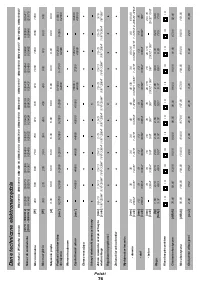

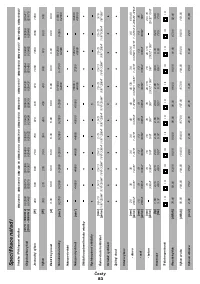

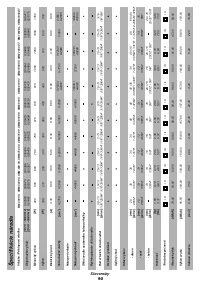

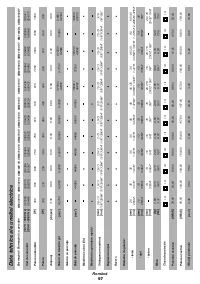

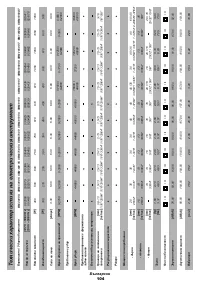

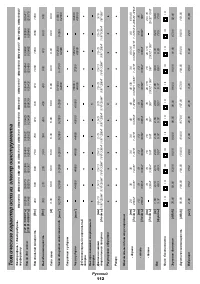

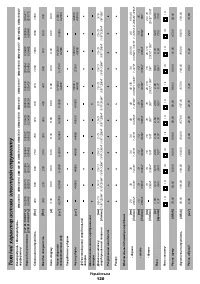

d u r i n g t h e t i g h t e n i n g f a s t e n i n g o f [SBM-500 VS, SBM-600 VS, SBM-750 VS, SBM-810 VS,

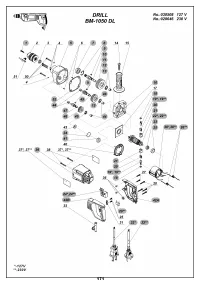

SBM-810 VT, SBM-1050 VS, SBM-1050 VT, BM-1050 DL,

components in order not to damage the

threaded connections.

SBM-1050 DT]

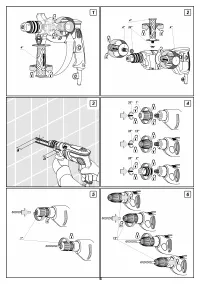

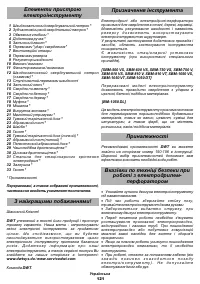

Auxiliary handle

Screw gear rim chuck

2

onto the power tool spindle

(see picture 4).

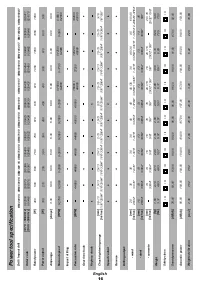

[SBM-500 VS, SBM-600 VS, SBM-750 VS, SBM-750 V,

Lock gear rim chuck

2

on the power tool spindle,

SBM-810 VS, SBM-810 V, SBM-810 VT, SBM-1050 VS,

having tightened screw

33

.

Attention: screw

33

has

SBM-1050 VT, BM-1050 DL, SBM-1050 DT]

left-a hand thread

. Prior to that move apart the cams of

gear rim chuck

2

at the distance allowing to tighten

When operating your tool hold additional handle

4

- it

screw

33

to be tightened. To do that, release the grip of

improves the operation performance comfort and the

the cams with clamping wrench

14

, then rotate the quill

electric tool control.

of gear rim chuck

2

counter-clockwise with your hand.

Additional handle

4

may be positioned as deemed

When gear rim chuck

2

is being dismounted, repeat

comfortable by the user.

the aforementioned operations in reverse order.

[SBM-500 VS, SBM-600 VS, SBM-750 VS, SBM-750 V,

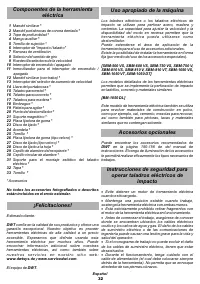

Mounting / replacement of accessories

SBM-810 VS, SBM-810 V, SBM-810 VT, SBM-1050 VS,

SBM-1050 VT, SBM-1050 DT]

It is necessary to wear gloves when

extracting the drill from the chuck

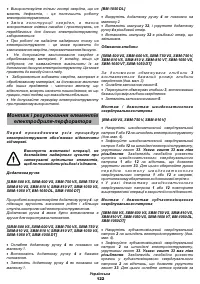

Loose additional handle

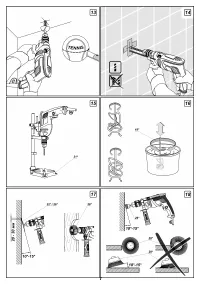

4

as shown in fig. 1.

because the drill can become very hot due

Place additional handle

4

in desired position.

to long operation. Wearing gloves when

Tighten additional handle

4

as shown in fig. 1.

mounting / replacing wire brushes is also

recommended.

[BM-1050 DL]

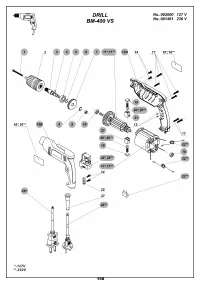

[BM-400 VS]

Release additional handle

4

as shown on picture 2.

Extract cork

32

and screw additional handle

4

into the

This model is equipped with keyless chuck

1

. This

threaded opening.

allows accessories to be mounted / replaced quickly and

Insert cork

32

into the freed threaded opening.

without a key.

Depth stop

Move the cams of keyless chuck

1

apart at the

distance allowing an accessory to be mounted /

[SBM-500 VS, SBM-600 VS, SBM-750 VS, SBM-750 V,

replaced. To do that, rotate the front part of keyless

SBM-810 VS, SBM-810 V, SBM-810 VT, SBM-1050 VS,

chuck

1

counter-clockwise with your hand (see picture 5).

SBM-1050 VT, SBM-1050 DT]

Mount / replace an accessory.

Use depth limiter

3

to set a required drilling depth (see fig. 3).

Rotate the front part of keyless chuck

1

clockwise with

Slacken clamp

5

.

your hand to lock the accessory mounted. Do not allow

Move depth limiter

3

to set a required drilling depth.

the accessory to become distorted.

Tighten clamp

5

.

[SBM-750 V, SBM-810 V]

Mounting / dismounting of the keyless chuck

These models are equipped with keyless chuck (with

12

[BM-400 VS, SBM-750 V, SBM-810 V]

lock)

. This allows accessories to be mounted /

replaced quickly and without a key and provides more

Screw keyless chuck

1

or

12

onto the power tool reliable locking of the accessory compared to an

ordinary keyless chuck.

spindle (see picture 4).

18