Шлифмашины AEG WS 2200-230 DMS - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

12

GB

English

b) Do not position your body in line with and behind the

rotating wheel.

When the wheel, at the point of operation, is moving

away from your body, the possible kickback may propel the spinning

wheel and the power tool directly at you.

c) When wheel is binding or when interrupting a cut for any

reason, switch off the power tool and hold the power tool

motionless until the wheel comes to a complete stop. Never

attempt to remove the cut-off wheel from the cut while the

wheel is in motion otherwise kickback may occur.

Investigate

and take corrective action to eliminate the cause of wheel binding.

d) Do not restart the cutting operation in the workpiece. Let

the wheel reach full speed and carefully re-enter the cut.

The

wheel may bind, walk up or kickback if the power tool is restarted in

the workpiece.

e) Support panels or any oversized workpiece to minimize the

risk of wheel pinching and kickback.

Large workpieces tend to sag

under their own weight. Supports must be placed under the workpiece

near the line of cut and near the edge of the workpiece on both sides

of the wheel.

f) Use extra caution when making a “pocket cut” into existing

walls or other blind areas.

The protruding wheel may cut gas or

water pipes, electrical wiring or objects that can cause kickback.

Safety Warnings Specific for Sanding Operations:

a) Do not use excessively oversized sanding disc paper.

Follow manufacturers recommendations, when selecting

sanding paper.

Larger sanding paper extending beyond the

sanding pad presents a laceration hazard and may cause snagging,

tearing of the disc or kickback.

Safety Warnings Specific for Wire Brushing Operations:

a) Be aware that wire bristles are thrown by the brush

even during ordinary operation. Do not overstress the wires

by applying excessive load to the brush.

The wire bristles can

easily penetrate light clothing and/or skin.

b) If the use of a guard is recommended for wire brushing,

do not allow any interference of the wire wheel or brush

with the guard.

Wire wheel or brush may expand in diameter due

to work load and centrifugal forces.

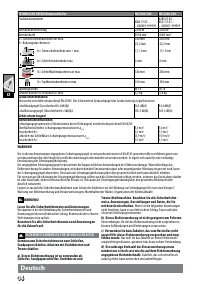

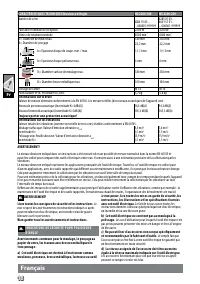

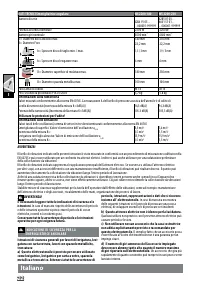

Additional Safety and Working Instructions

When grinding metal, flying sparks are produced. Take care that

no persons are endangered. Because of the danger of fire, no

combustible materials should be located in the vicinity (spark flight

zone). Do not use dust extraction.

Avoid flying sparks and sanding dust hit your body.

Never reach into the danger area of the machine when it is running.

Chips and splinters must not be removed while the machine is

running.

Immediately switch off the machine in case of considerable vibra-

tions or if other malfunctions occur. Check the machine in order to

find out the cause.

Under extreme conditions (e.g. smooth-grinding metals with

the arbour and vulcanized fibre grinding disk), significant

contamination can build up on the inside of the angle grinder. For

safety reasons, in such conditions a ground fault interrupter must

be connected in series. If the ground fault interrupter trips the

machine must be sent for service.

Do not let any metal parts enter the airing slots - danger of short

circuit!

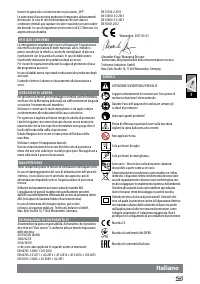

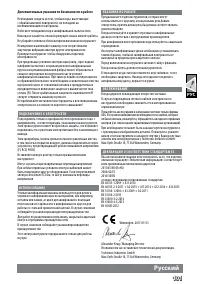

MAINS CONNEC TION

Connect only to single-phase AC system voltage as indicated on

the rating plate. It is also possible to connect to sockets without an

earthing contact as the design conforms to safety class II.

Appliances used at many different locations including wet room

and open air must be connected via a residual current device (FI,

RCD, PRCD) of 30mA or less.

Only plug-in when machine is switched off.

Inrush currents cause short-time voltage drops. Under unfavoura-

ble power supply conditions, other equipment may be affected. If

the system impedance of the power supply is lower than 0,2 Ohm,

disturbances are unlikely to occur.

SPECIFIED CONDITIONS OF USE

The angle grinder is intended for grinding and cutting metal, stone

and ceramic materials as well as sanding and wire brushing.

Use the cutting guard from the accessories range for cutting

application.

Please refer to the instructions supplied by the accessory

manufacturer.

The machine is suitable only for working without water.

WORKING INSTRUC TIONS

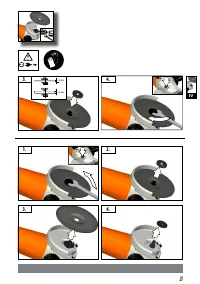

For accessories intended to be fitted with threaded hole wheel,

ensure that the thread in the wheel is long enough to accept the

spindle length.

Always use and store the cutting and grinding disks according to

the manufacturer‘s instructions.

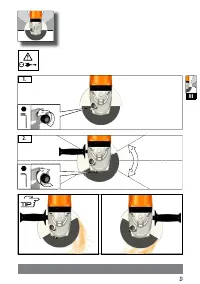

Always use the correct guard for cutting and grinding.

The grinding surface of the centre depressed disks must be moun-

ted min. 2 mm below the plane of the guard lip.

The adjusting nut must be tightened before starting to work with

the machine.

Always use the auxiliary handle.

The workpiece must be fixed if it is not heavy enough to be steady.

Never move the workpiece towards the rotating disk by hand.

MAINTENANCE

The ventilation slots of the machine must be kept clear at all times.

If the supply cord of this power tool is damaged, it must be

replaced by a specially prepared cord available through the service

organization.

Use only AEG accessories and spare parts. Should components need to

be replaced which have not been described, please contact one of our

AEG service agents (see our list of guarantee/service addresses).

If needed, an exploded view of the tool can be ordered. Please state

the Article No. as well as the machine type printed on the label

and order the drawing at your local service agents or directly at:

Techtronic Industries GmbH, Max-Eyth-Straße 10, 71364 Winnen-

den, Germany.

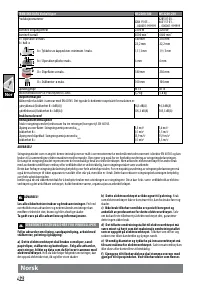

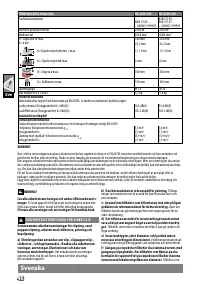

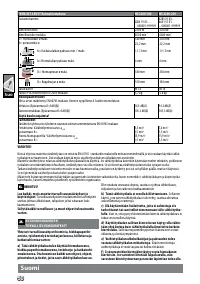

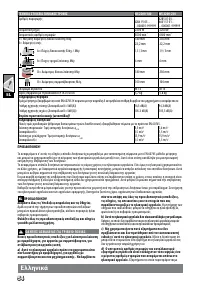

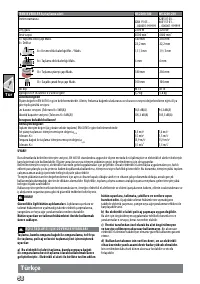

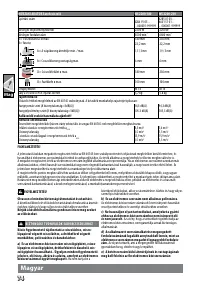

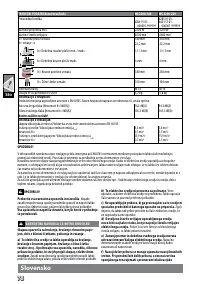

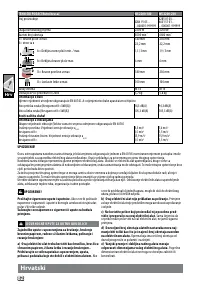

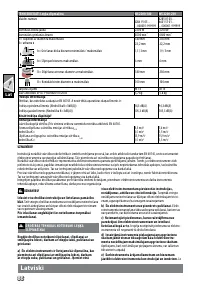

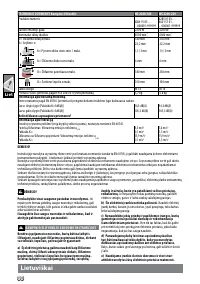

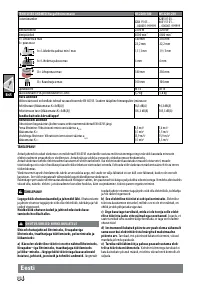

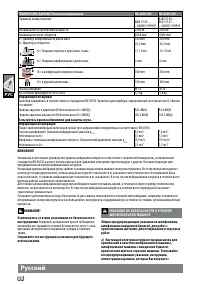

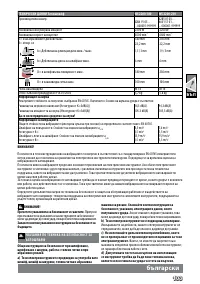

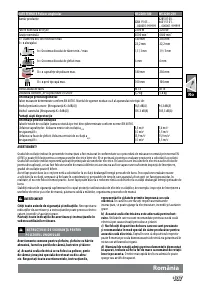

Характеристики

Остались вопросы?Не нашли свой ответ в руководстве или возникли другие проблемы? Задайте свой вопрос в форме ниже с подробным описанием вашей ситуации, чтобы другие люди и специалисты смогли дать на него ответ. Если вы знаете как решить проблему другого человека, пожалуйста, подскажите ему :)