Шуруповерты Makita BTD136RFE - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

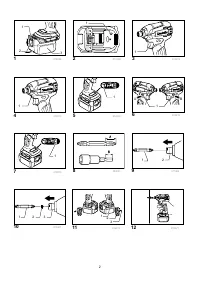

8

re-inserting the bit according to the instructions

above.

•

When it is difficult to insert the bit, pull the sleeve

and insert it into the sleeve as far as it will go.

•

After inserting the bit, make sure that it is firmly

secured. If it comes out, do not use it.

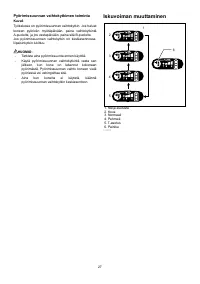

Hook

Fig.11

The hook is convenient for temporarily hanging the tool.

This can be installed on either side of the tool.

To install the hook, insert it into a groove in the tool

housing on either side and then secure it with a screw. To

remove, loosen the screw and then take it out.

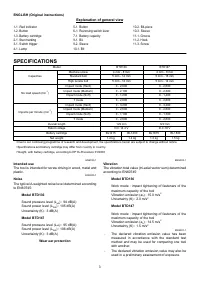

OPERATION

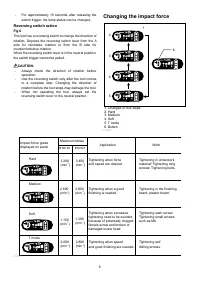

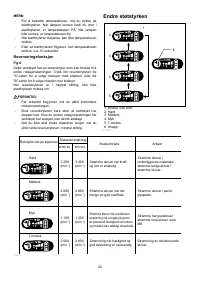

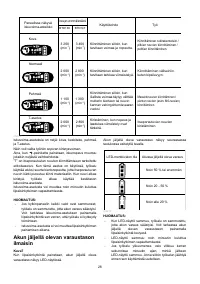

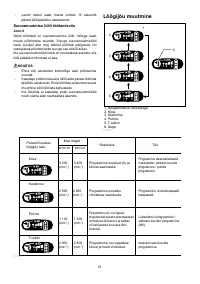

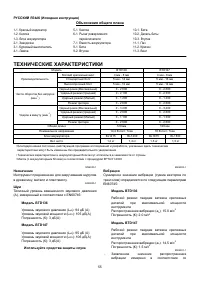

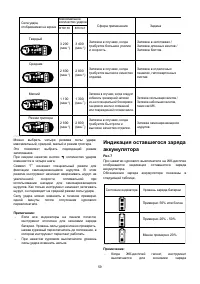

Fig.12

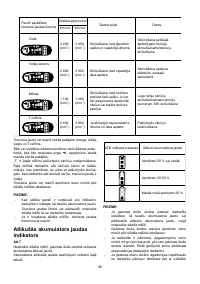

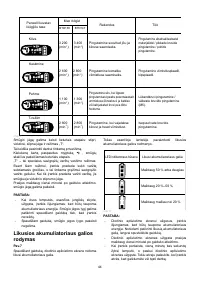

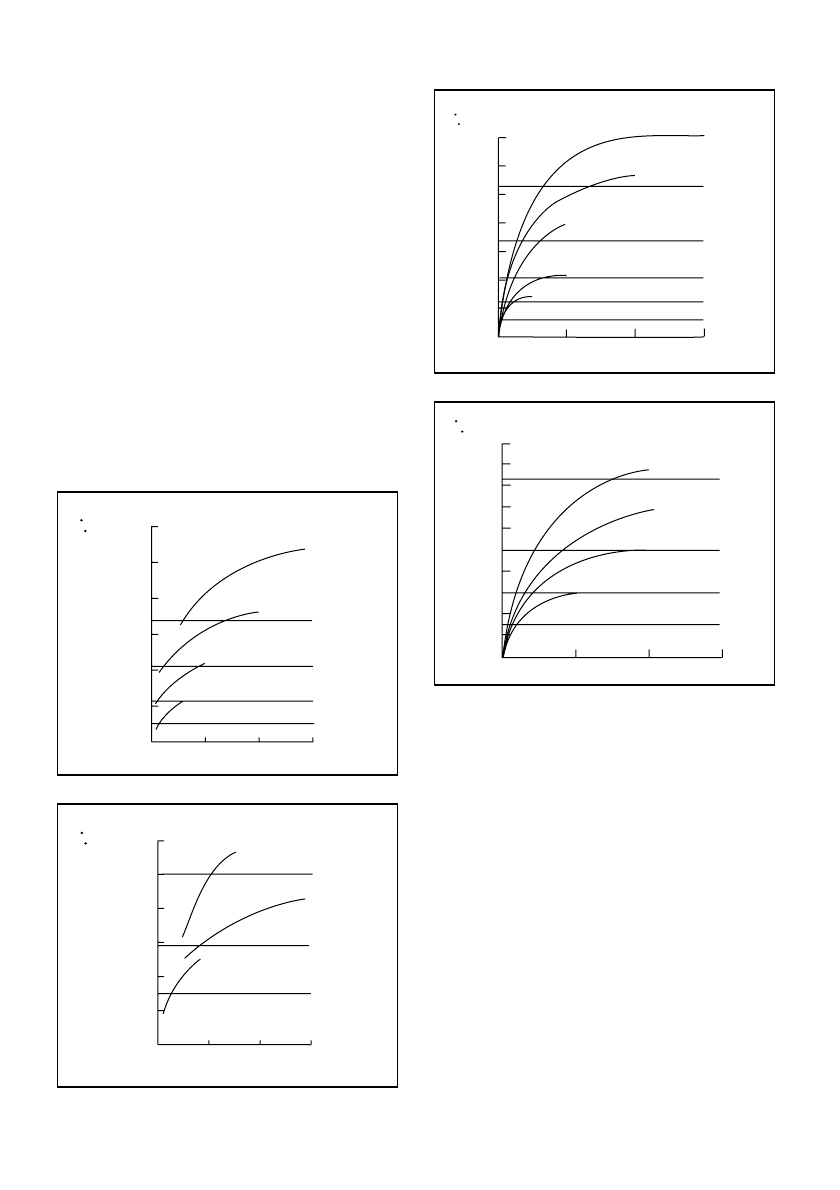

The proper fastening torque may differ depending upon

the kind or size of the screw/bolt, the material of the

workpiece to be fastened, etc. The relation between

fastening torque and fastening time is shown in the

figures.

Model BTD136

120

100

80

60

40

20

0

1.0

2.0

3.0

M14

M12

M10

M8

(M14)

(M12)

(M10)

(M8)

Standard bolt

N m

Fastening torque

Fastening time (S)

Proper fastening torque

(kgf cm) (1224)

(1020)

(816)

(612)

(408)

(204)

009218

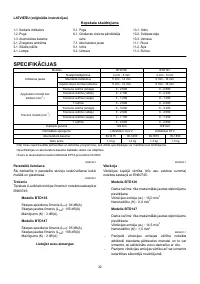

120

(122

4

)

100

(1020)

80

(816)

60

(612)

4

0

(

4

08)

20

(20

4

)

0

1

.

0

2

.

0

3

.

0

M12

M10

M8

(M12)

(M10)

(M8)

N

m

F

asten

i

ng

torque

F

asten

i

ng

t

i

me

(S)

Proper

fasten

i

ng

torque

(kgf

cm)

Hi

gh

tens

il

e

bo

l

t

009219

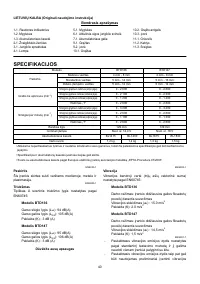

Model BTD147

120

100

80

60

40

20

M14

M12

M10

M8

(M14)

(M12)

(M10)

(M8)

Standard bolt

N m

Fastening torque

Fastening time (S)

Proper fastening torque

(kgf cm)

(1224)

(1020)

(816)

(612)

(408)

(204)

0

140

(1428)

1.0

2.0

3.0

M16

(M16)

012775

0

High tensile bolt

Fastening torque

Fastening time (S)

Proper fastening torque

1.0

2.0

3.0

(M14)

M14

M12

(M12)

M10

(M10)

200

(2040)

180

(1836)

(M8)

160

(1632)

140

(1428)

120

(1224)

100

(1020)

80

(816)

60

(612)

40

(408)

20

(204)

N m

(kgf cm)

M8

012774

Hold the tool firmly and place the point of the driver bit in

the screw head. Apply forward pressure to the tool to the

extent that the bit will not slip off the screw and turn the

tool on to start operation.

NOTE:

•

Use the proper bit for the head of the screw/bolt

that you wish to use.

•

When fastening M8 or smaller screw, choose a

proper impact force and carefully adjust pressure

on the switch trigger so that the screw is not

damaged.

•

Hold the tool pointed straight at the screw.

•

If the impact force is too strong you tighten the

screw for a time longer than shown in the figures,

the screw or the point of the driver bit may be

overstressed, stripped, damaged, etc. Before

starting your job, always perform a test operation to

determine the proper fastening time for your screw.

The fastening torque is affected by a wide variety of

factors including the following. After fastening, always

check the torque with a torque wrench.