Шуруповерты Bosch GDR 180-LI 06019G5123 - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

English |

17

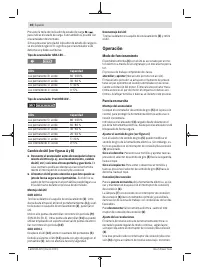

Starting Operation

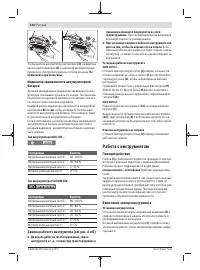

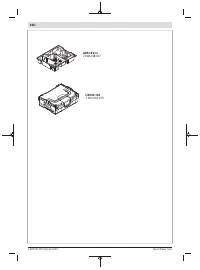

Inserting the Battery

Set the rotational direction switch

(5)

to the centre position

to protect the power tool from being switched on accident-

ally.

Push the charged battery

(3)

into the base of the power tool

from the front until the battery is securely locked.

Set the rotational direction (see figure C)

The rotational direction switch

(5)

is used to change the ro-

tational direction of the power tool. However, this is not pos-

sible while the on/off switch

(6)

is being pressed.

Right rotation:

To drive in screws and tighten nuts, press

the rotational direction switch

(5)

through to the left stop.

Left Rotation:

To loosen and unscrew screws and nuts,

press the rotational direction switch

(5)

through to the right

stop.

Switching on/off

To

start

the power tool, press and hold the on/off switch

(6)

.

The lamp

(7)

lights up when the on/off switch

(6)

is lightly or

fully pressed, meaning that the work area is illuminated in

poor lighting conditions.

To

switch off

the power tool, release the on/off switch

(6)

.

Adjusting the Speed

You can adjust the speed of the power tool when it is on by

pressing in the on/off switch

(6)

to varying extents.

A light pressure on the on/off switch

(6)

results in a low rota-

tional speed. Increased pressure on the switch causes an in-

crease in speed.

Practical advice

u

Only apply the power tool to the screw/nut when the

tool is switched off.

Rotating tool inserts can slip off.

The torque depends on the impact duration. The maximum

achieved torque results from the sum of all individual

torques achieved through impact. Maximum torque is

achieved after an impact duration of 6–10 seconds. After

this duration, the tightening torque increases only minimally.

The impact duration is to be determined for each required

tightening torque. The tightening torque actually achieved

should always be checked with a torque wrench.

Screw applications with hard, spring-loaded or soft seats

When the achieved torques in an impact series are measured

during a test and transferred onto a diagram, the result is the

curve of a torque characteristic. The height of the curve cor-

responds to the maximum achievable torque, and the steep-

ness indicates the duration in which this is achieved.

A torque characteristic depends on the following factors:

– Strength properties of the screws/nuts

– Type of backing (washer, disc spring, seal)

– Strength properties of the material being screwed/bolted

together

– Lubrication conditions at the screw/bolt connection

Consequently, the following applies in each case:

– A

hard seat

is used for metal-to-metal screw applications

that use washers. After a relatively short impact duration,

the maximum torque is achieved (steep characteristic

curve). An unnecessarily long impact duration only

causes damage to the machine.

– A

spring-loaded seat

is used for metal-to-metal screw

applications that use spring washers, disc springs, studs

or screws/nuts with conical seats. It is also called a

spring-loaded seat when extensions are used.

– A

soft seat

is used for screw applications of e.g. metal on

wood or screw applications that use lead washers or fibre

washers as backing.

For a spring-loaded seat, as well as for a soft seat, the max-

imum tightening torque is lower than for a hard seat. A much

longer impact duration is also required.

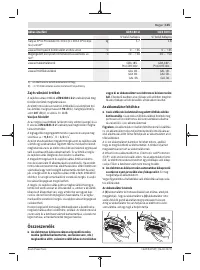

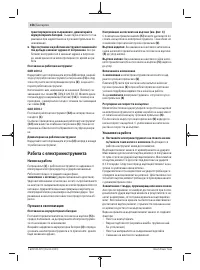

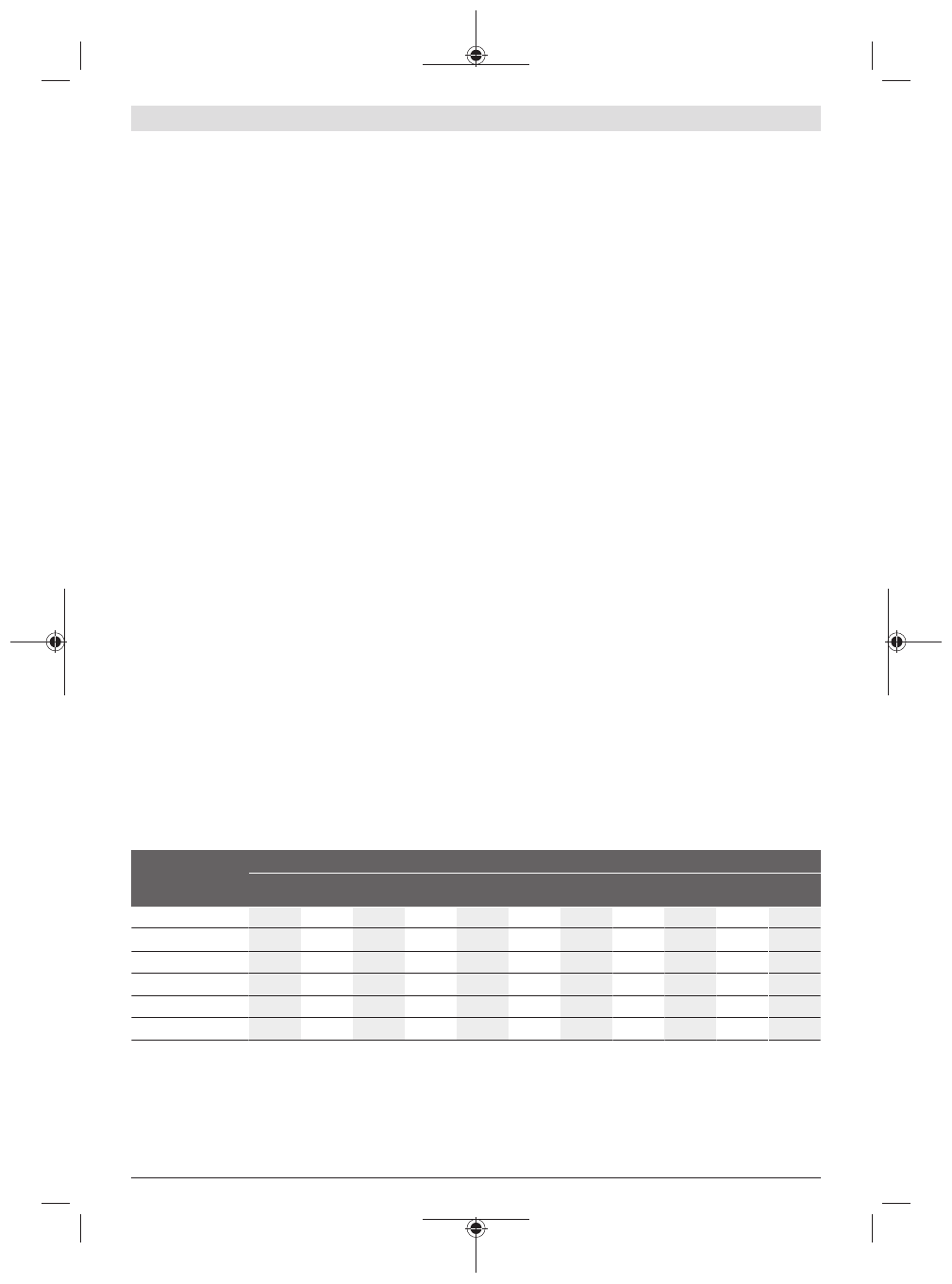

Guide values for maximum screw tightening torques

Figures given in Nm; calculated from the tensional cross-section; utilization of the yield point: 90% (with friction coefficient

µ

total

= 0.12). As a control measure, always check the tightening torque with a torque wrench.

Property Classes

according to

DIN 267

Standard Screws/Bolts

High-strength Bolts

3.6

4.6

5.6

4.8

6.6

5.8

6.8

6.9

8.8

10.9

12.9

M6

2.71

3.61

4.52

4.8

5.42

6.02

7.22

8.13

9.7

13.6

16.2

M8

6.57

8.7

11

11.6

13.1

14.6

17.5

19.7

23

33

39

M10

13

17.5

22

23

26

29

35

39

47

65

78

M12

22.6

30

37.6

40

45

50

60

67

80

113

135

M14

36

48

60

65

72

79

95

107

130

180

215

M16

55

73

92

98

110

122

147

165

196

275

330

Tips

Before screwing larger, longer screws into hard materials, it

is advisable to pre-drill a pilot hole with the core diameter of

the thread to approx. 2/3 of the screw length.

Note:

Ensure that no metal particles enter the power tool.

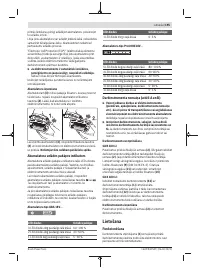

Belt clip

You can use the belt clip to hang the power tool on a belt, for

example. You then have both hands free and the power tool

is always at hand.

Bosch Power Tools

1 609 92A 5XY | (26.04.2021)