Перфораторы STATUS MPR31 - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

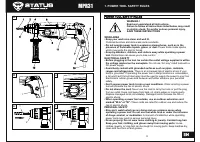

• The side grip swings around to either side, allowing easy handling of the tool in

any position. Loosen the side handle by turning it counterclockwise, swing it to

the desired position and then tighten it by turning clockwise.

INSTALLING OR REMOVING THE BIT (Fig. D, E)

•

Clean the bit shank and apply bit grease before installing the bit.

•

Insert the bit (1) into the tool. Turn the bit and push it in until it engages.

•

If the bit cannot be pushed in, remove the bit. Pull the chuck cover (2) down a

couple of times. Then insert the bit again. Turn the bit and push it in until it

engages.

•

After installing, always make sure that the bit is securely held in place by trying

to pull it out.

•

To remove the bit, pull the chuck cover (2) down all the way and pull the bit out.

DEPTH GAUGE

•

The depth gauge is convenient for drilling holes of uniform depth. Insert the

depth gauge into the hole in the grip base.

•

Adjust the depth gauge to the desired depth and then tighten the side handle to

secure the depth gauge.

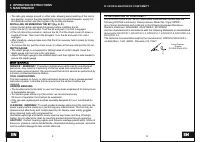

MAINTENANCE

SERVICE : WARNING !

Preventive maintenance performed by unauthorized

personnel may result in misplacing of internal wires and components which

could cause serious hazard. We recommend that all tool service be performed by

a Factory Authorized Service Station.

TOOL LUBRICATIONS

This tool requires no hourly or daily lubrication because it has a grease-packed

lubrication system. Lubricate the tool every time the carbon brushes are

replaced.

CARBON BRUSHES

•

The brushes and commutator in your tool have been engineered for many hours

of dependable service.

•

To maintain peak efficiency of the motor, we recommend every

50 hours of operation the brushes be examined.

•

Only genuine replacement brushes specially designed for your tool should be

used.

CLEANING: WARNING !

To avoid accidents always disconnect the tool from the

power supply before cleaning or performing any maintenance. The tool may be

cleaned most effectively with compressed dry air. Always wear safety goggles

when cleaning tools with compressed air.

Ventilation openings and switch levers must be kept clean and free of foreign

matter. Do not attempt to clean by inserting pointed objects through openings.

CAUTION !

Certain cleaning agents and solvents damage plastic parts. Some of

these are: gasoline, carbon tetrachloride, chlorinated cleaning solvents, ammonia

and household detergents that contain a8monia.

4. OPERATING INSTRUCTIONS

5. MAINTENANCE

CE DECLARATION OF CONFORMITY

We STATUS ITALIA S.R.L. as the responsible manufacturer declare that the

following STATUS machine(s): Rotary hammer Model No./ Type: MPR31

are of series production and сonforms to the following European Directives:

Machine Directives: 2006/42/EC, 2004/108/EC, 2011/65EU

And are manufactured in accordance with the following standards or standardised

documents:

EN 60745-1, EN 60745-2-3, EN 55014-1, EN 55014-2, EN 61000-3-2,

EN 61000-3-3.

The technical documentation kept by the manufacturer: STATUS ITALIA S.R.L.,

via Aldo Moro, 14/A, 36060 - Pianezze (VI), ITALY

Caron Giacinto

Director

STATUS ITALIA S.R.L.

6.

CE DECLARATION OF CONFORMITY

8

9

Характеристики

Остались вопросы?Не нашли свой ответ в руководстве или возникли другие проблемы? Задайте свой вопрос в форме ниже с подробным описанием вашей ситуации, чтобы другие люди и специалисты смогли дать на него ответ. Если вы знаете как решить проблему другого человека, пожалуйста, подскажите ему :)