Гайковерты Bosch GDS 18V-1000 (06019J8300) - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

English |

21

Status indicator for power

tool (11)

Meaning/cause

Solution

Flashing blue

Power tool is connected to a mobile device or

settings are being transferred

–

Speed preselection

With the speed preselection button

(16)

, you can preselect

the required speed in three stages. Press button

(16)

as of-

ten as needed until the required setting is indicated in the

speed indicator

(17)

. The selected setting will be saved.

GDS 18V-1000 C / GDS 18V-1050 HC:

You can also preselect the speed using the Bosch Toolbox

app.

The required speed depends on the material and the work-

ing conditions; it can be ascertained through practical tests.

The information in the table below describes the recommen-

ded values.

Basic speed setting at level

1

2

3

[min

-1

]

[min

-1

]

[min

-1

]

Number of speed settings

3

0–1 100 0–2 300 0–3 400

You can use the button for speed preselection

(16)

to

preselect the required speed, even during operation.

Switching On the Worklight

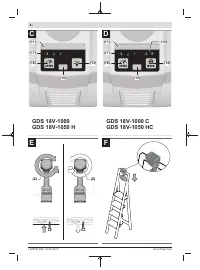

GDS 18V-1000 / GDS 18V-1050 H:

To switch the worklight

(15)

on or off, press the worklight

button

(13)

.

u

Do not look directly into the worklight; it can blind

you.

Selecting the working mode

GDS 18V-1000 C / GDS 18V-1050 HC:

The power tool has two preset working modes

A

and

B

(12)

.

You can also programme working modes for different applic-

ations and adjust existing modes via the Bosch Toolbox un-

der

A

and

B

(12)

.

To switch between the working modes

A

and

B

(12)

, press

button

(14)

.

Practical advice

u

Only apply the power tool to the screw/nut when the

tool is switched off.

Rotating tool inserts can slip off.

u

The power tool with inserted

Bluetooth

®

Low Energy

Module

GCY 42 (accessory) is equipped with a radio

interface. Local operating restrictions, e.g. in aircraft

or hospitals, must be observed.

The torque depends on the impact duration. The maximum

achieved torque results from the sum of all individual

torques achieved through impact. Maximum torque is

achieved after an impact duration of 6–10 seconds. After

this duration, the tightening torque increases only minimally.

The impact duration is to be determined for each required

tightening torque. The tightening torque actually achieved

should always be checked with a torque wrench.

Screw applications with hard, spring-loaded or soft seats

When the achieved torques in an impact series are measured

during a test and transferred into a diagram, the result is the

curve of a torque characteristic. The height of the curve cor-

responds with the maximum reachable torque, and the

steepness indicates the duration in which this is achieved.

A torque gradient depends on the following factors:

– Strength properties of the screws/nuts

– Type of backing (washer, disc spring, seal)

– Strength properties of the material being screwed/bolted

together

– Lubrication conditions at the screw/bolt connection

The following application cases result accordingly:

– A

hard seat

is a metal-to-metal screw application which

uses washers. After a relatively short impact duration, the

maximum torque is reached (steep characteristic curve).

Unnecessary long impact duration only causes damage to

the machine.

– A

spring-loaded seat

is also a metal-to-metal screw ap-

plication but uses spring washers, disc springs, studs or

screws/nuts with conical seats. It is also called a spring-

loaded seat when extensions are used.

– A

soft seat

is a screw application of e.g. metal on wood or

a screw application that uses lead washers or fibre wash-

ers as backing.

For a spring-loaded seat as well as for a soft seat, the max-

imum tightening torque is lower than for a hard seat. Also, a

clearly longer impact duration is required.

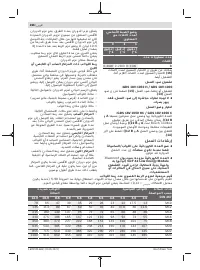

Guide values for maximum screw tightening torques

Figures given in Nm; calculated from the tensional cross-section; utilisation of the yield point: 90% (with friction coefficient

µ

total

= 0.12). As a control measure, always check the tightening torque with a torque wrench.

Property classes

according to DIN

267

Standard screws

High-strength screws

3.6

4.6

5.6

4.8

6.6

5.8

6.8

6.9

8.8

10.9

12.9

M10

13

17.5

22

23

26

29

35

39

47

65

78

M12

22.6

30

37.6

40

45

50

60

67

80

113

135

M14

36

48

60

65

72

79

95

107

130

180

215

Bosch Power Tools

1 609 92A 6HU | (10.05.2021)

Содержание

- 149 Применение электроинструмента и обращение с ним

- 150 Описание продукта и услуг; Применение по назначению

- 151 Пользовательский интерфейс; Технические данные

- 152 Данные по шуму и вибрации

- 153 Сборка; Зарядка аккумулятора; Извлечение аккумулятора; Монтаж модуля; ® Low Energy GCY 42; Работа с инструментом; Принцип действия; заворачивание

- 154 Включение электроинструмента; Решение

- 155 Указания по применению; Стандартные винты

- 156 Управление при помощи приложения; Техобслуживание и сервис; Техобслуживание и очистка

- 157 Россия; Транспортировка

Характеристики

Остались вопросы?Не нашли свой ответ в руководстве или возникли другие проблемы? Задайте свой вопрос в форме ниже с подробным описанием вашей ситуации, чтобы другие люди и специалисты смогли дать на него ответ. Если вы знаете как решить проблему другого человека, пожалуйста, подскажите ему :)