Фрезеры Makita M3602 - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

10 ENGLISH

Switch action

CAUTION:

Before plugging in the tool, always

check to see that the tool is switched off.

CAUTION:

Make sure that the shaft lock is

released before the switch is turned on.

To start the tool, move the switch lever to the I position.

To stop the tool, move the switch lever to the O position.

►

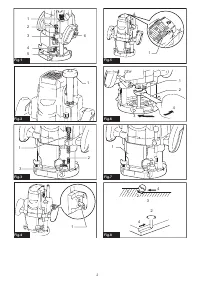

Fig.4:

1.

Switch lever

CAUTION:

Hold the tool firmly when turning

off the tool, to overcome the reaction.

Electronic function

The tool is equipped with the electronic functions for

easy operation.

Indication lamp

►

Fig.5:

1.

Indication lamp

The indication lamp lights up green when the tool is

plugged. If the indication lamp does not light up, the

mains cord or the controller may be defective. The indi

-

cation lamp is lit but the tool does not start even if the

tool is switched on, the carbon brushes may be worn

out, or the controller, the motor or the ON/OFF switch

may be defective.

Unintentional restart proof

The tool does not start with the switch lever is in the I

position even when the tool is plugged.

At this time, the indication lamp blinks in red and shows

the unintentional restart proof device is on function.

To cancel the unintentional restart proof, move the

switch lever to the O position.

Soft start feature

Soft-start feature minimizes start-up shock, and makes

the tool start smoothly.

ASSEMBLY

CAUTION:

Always be sure that the tool is

switched off and unplugged before carrying out

any work on the tool.

Installing or removing the router bit

Insert the router bit all the way into the collet cone.

Press the shaft lock to keep the shaft stationary and

use the wrench to tighten the collet nut securely. When

using router bits with smaller shank diameter, first insert

the appropriate collet sleeve into the collet cone, then

install the router bit.

To remove the router bit, follow the installation proce

-

dure in reverse.

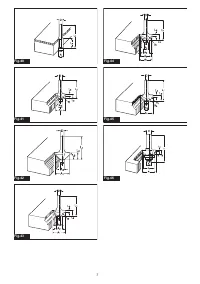

►

Fig.6:

1.

Shaft lock

2.

Wrench

3.

Loosen

4.

Tighten

CAUTION:

Install the router bit securely.

Always use only the wrench provided with the

tool.

A loose or overtightened router bit can be

dangerous.

NOTICE:

Do not tighten the collet nut without

inserting a router bit or install small shank bits

without using a collet sleeve.

Either can lead to

breakage of the collet cone.

OPERATION

CAUTION:

Before operation, always make

sure that the tool body automatically rises to

the upper limit and the router bit does not pro

-

trude from the tool base when the lock lever is

loosened.

CAUTION:

Before operation, always make

sure that the chip deflector is installed properly.

CAUTION:

Always use both grips and firmly

hold the tool by both grips during operations.

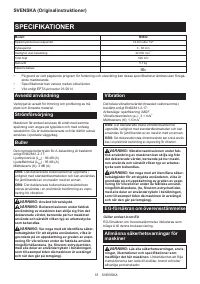

►

Fig.7:

1.

Chip deflector

Set the tool base on the workpiece to be cut without

the router bit making any contact. Then turn the tool on

and wait until the router bit attains full speed. Lower the

tool body and move the tool forward over the workpiece

surface, keeping the tool base flush and advancing

smoothly until the cutting is complete.

When doing edge cutting, the workpiece surface should

be on the left side of the router bit in the feed direction.

►

Fig.8:

1.

Workpiece

2.

Bit revolving direction

3.

View from the top of the tool

4.

Feed

direction

NOTE:

Moving the tool forward too fast may cause

a poor quality of cut, or damage to the router bit or

motor. Moving the tool forward too slowly may burn

and mar the cut. The proper feed rate will depend on

the router bit size, the kind of workpiece and depth

of cut.

Before beginning the cut on the actual workpiece, it

is advisable to make a sample cut on a piece of scrap

lumber. This will show exactly how the cut will look as

well as enable you to check dimensions.

NOTE:

When using the straight guide or the trimmer

guide, be sure to install it on the right side in the feed

direction. This will help to keep it flush with the side of

the workpiece.

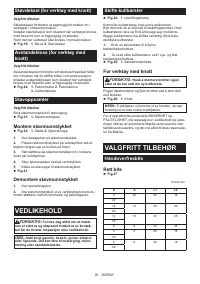

►

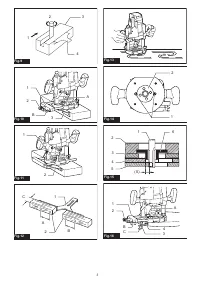

Fig.9:

1.

Feed direction

2.

Bit revolving direction

3.

Workpiece

4.

Straight guide

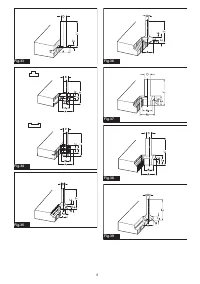

Содержание

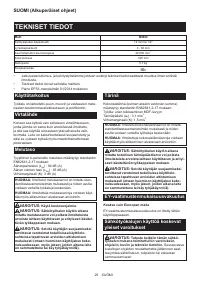

- 64 ТЕХНИЧЕСКИЕ ХАРАКТЕРИСТИКИ; Назначение; Вибрация

- 65 Общие рекомендации по; Сохраните брошюру с инструк; Правила техники безопасности; СОХРАНИТЕ ДАННЫЕ

- 66 ОПИСАНИЕ РАБОТЫ; Регулировка глубины реза

- 67 Защита от случайного включения; СБОРКА; Установка или снятие фрезы; ЭКСПЛУАТАЦИЯ; Прямая направляющая

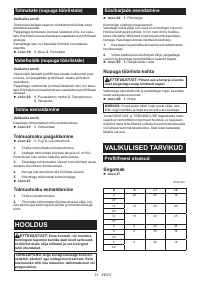

- 68 Профильная направляющая; Кромкообрезная направляющая; Пылезащитный кожух (для

- 69 Проставка (для инструмента с; Сбор пыли; Установка пылесборного патрубка; ОБСЛУЖИВАНИЕ; Замена угольных щеток; ДОПОЛНИТЕЛЬНЫЕ; Фрезы

Характеристики

Остались вопросы?Не нашли свой ответ в руководстве или возникли другие проблемы? Задайте свой вопрос в форме ниже с подробным описанием вашей ситуации, чтобы другие люди и специалисты смогли дать на него ответ. Если вы знаете как решить проблему другого человека, пожалуйста, подскажите ему :)