Фрезеры Bosch GOF 130 - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

English |

17

Operation

u

Products that are only sold in AUS and NZ:

Use a resid-

ual current device (RCD) with a nominal residual current

of 30 mA or less.

u

Pay attention to the mains voltage. The voltage of the

power source must match the voltage specified on the

rating plate of the power tool. Power tools marked

with 230 V can also be operated with 220 V.

Starting Operation

Preselecting the speed

You can preselect the required speed using the speed

preselection thumbwheel

(20)

, even during operation.

1−2

low speed

3−4

medium speed

5−6

high speed

The values shown in the table are guide values. The required

speed is dependent on the material and the work conditions

and can be determined by practical trials.

Material

Router bit

diameter [mm]

Thumbwheel

position

Hardwood (beech)

4–10

12–20

22–40

5–6

3–4

1–2

Softwood (pine)

4–10

12–20

22–40

5–6

3–6

1–3

Chipboard

4–10

12–20

22–40

3–6

2–4

1–3

Plastics

4–15

16–40

2–3

1–2

Aluminium

4–15

16–40

1–2

1

Switching On and Off

Before switching on/off, set the required routing depth.

To

switch on

the power tool,

first

press the lock button

(1)

,

then press and hold the on/off switch

(19)

.

Press the lock button

(1)

again to

lock

the on/off

switch

(19)

.

To

switch off

, release the on/off switch

(19)

. If the on/off

switch

(19)

is locked with the lock button

(1)

, briefly press

the on/off switch

(19)

and then release it.

Constant electronic control

The Constant Electronic keeps the speed at no load and un-

der load virtually consistent, guaranteeing uniform perform-

ance.

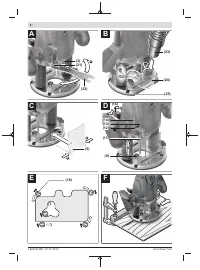

Setting the routing depth (see figure D)

The routing depth must only be set while the power tool is

switched off.

To set the rough routing depth, proceed as follows:

– Place the power tool with a fitted router bit onto the work-

piece you want to machine.

– Set the step buffer

(9)

to the lowest step; the step buffer

audibly clicks into place.

– Loosen the wing bolt on the depth stop

(11)

so that the

depth stop

(13)

moves freely.

– Push the clamping lever for locking the routing

depth

(16)

in direction

➊

and slowly move the router

down until the router bit

(18)

is touching the surface of

the workpiece. Release the clamping lever for locking the

routing depth

(16)

again to lock this depth. If necessary,

push the clamping lever for locking the routing

depth

(16)

in direction

➋

to fully lock it.

– Press the depth stop

(13)

down until it is resting on the

step buffer

(9)

. Set the slide with the index mark

(12)

to

position

0

on the routing depth scale

(14)

.

– Set the depth stop

(13)

to the required routing depth and

tighten the wing bolt on the depth stop

(11)

. Take care

not to accidentally move the index mark

(12)

.

– Push the clamping lever for locking the routing

depth

(16)

in direction

➊

and move the router to the

highest position.

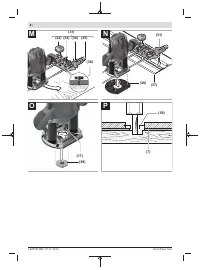

For larger routing depths, you should perform the cut in sev-

eral phases, so that only a small amount of material is re-

moved after each cut. You can use the step buffer

(9)

to di-

vide the routing process into several steps. To do this, set

the required routing depth with the smallest step of the step

buffer and, for the first cutting phases, select the higher

steps to start with.

Working Advice

u

Protect router bits against shock and impact.

u

Pull the plug out of the socket before carrying out any

work on the power tool.

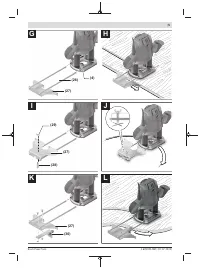

Routing direction and routing process (see figure E)

u

Routing must always be carried out with the work-

piece being moved against the direction in which the

router bit

(18) is turning (up cut).

If the workpiece is

moved in the same direction as the router bit is turning

(down cut), the power tool may be pulled out of your

hands.

Set the required routing depth.

Place the power tool with a fitted router bit onto the work-

piece you want to machine and switch on the power tool.

Push the clamping lever for locking the routing depth

(16)

down and slowly move the router down until it reaches the

set routing depth. Release the clamping lever for locking the

routing depth

(16)

again to lock this depth. If necessary,

push the clamping lever for routing depth stop

(16)

up to

fully lock it.

Carry out the routing process with a uniform feed.

When routing is complete, move the router back to the

highest position.

Switch the power tool off.

Bosch Power Tools

1 609 92A 5MT | (27.07.2020)

Содержание

- 115 Указания по технике безопасности; ЖДЕНИЕ

- 117 Описание продукта и услуг; Применение по назначению

- 118 Технические данные; Данные по шуму и вибрации

- 119 Сборка; Удаление пыли и стружки; Работа с инструментом; Включение электроинструмента

- 120 Указания по применению

- 122 Техобслуживание и сервис; Техобслуживание и очистка

- 123 Утилизация; Українська; Вказівки з техніки безпеки; ДЖЕННЯ

Характеристики

Остались вопросы?Не нашли свой ответ в руководстве или возникли другие проблемы? Задайте свой вопрос в форме ниже с подробным описанием вашей ситуации, чтобы другие люди и специалисты смогли дать на него ответ. Если вы знаете как решить проблему другого человека, пожалуйста, подскажите ему :)