Фрезеры Bosch GKF 550 - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

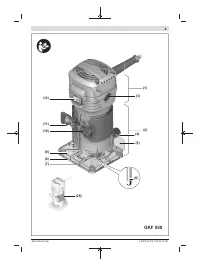

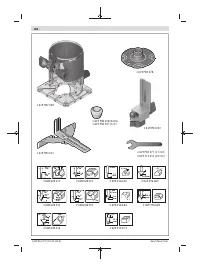

(15)

Tool holder

(16)

Open-end spanner (10 mm)

A)

(17)

Open-end spanner (17 mm)

A)

(18)

Guide bushing

A)

(19)

Parallel guide

A)

(20)

Wing bolt for parallel guide

A)

(21)

Pilot

A)

(22)

Wing bolt for fixing the horizontal alignment

A)

(23)

Wing bolt for horizontal alignment of the pilot

A)

(24)

Guide roller

A)

(25)

Handle (insulated gripping surface)

A)

Accessories shown or described are not included with the

product as standard. You can find the complete selection of

accessories in our accessories range.

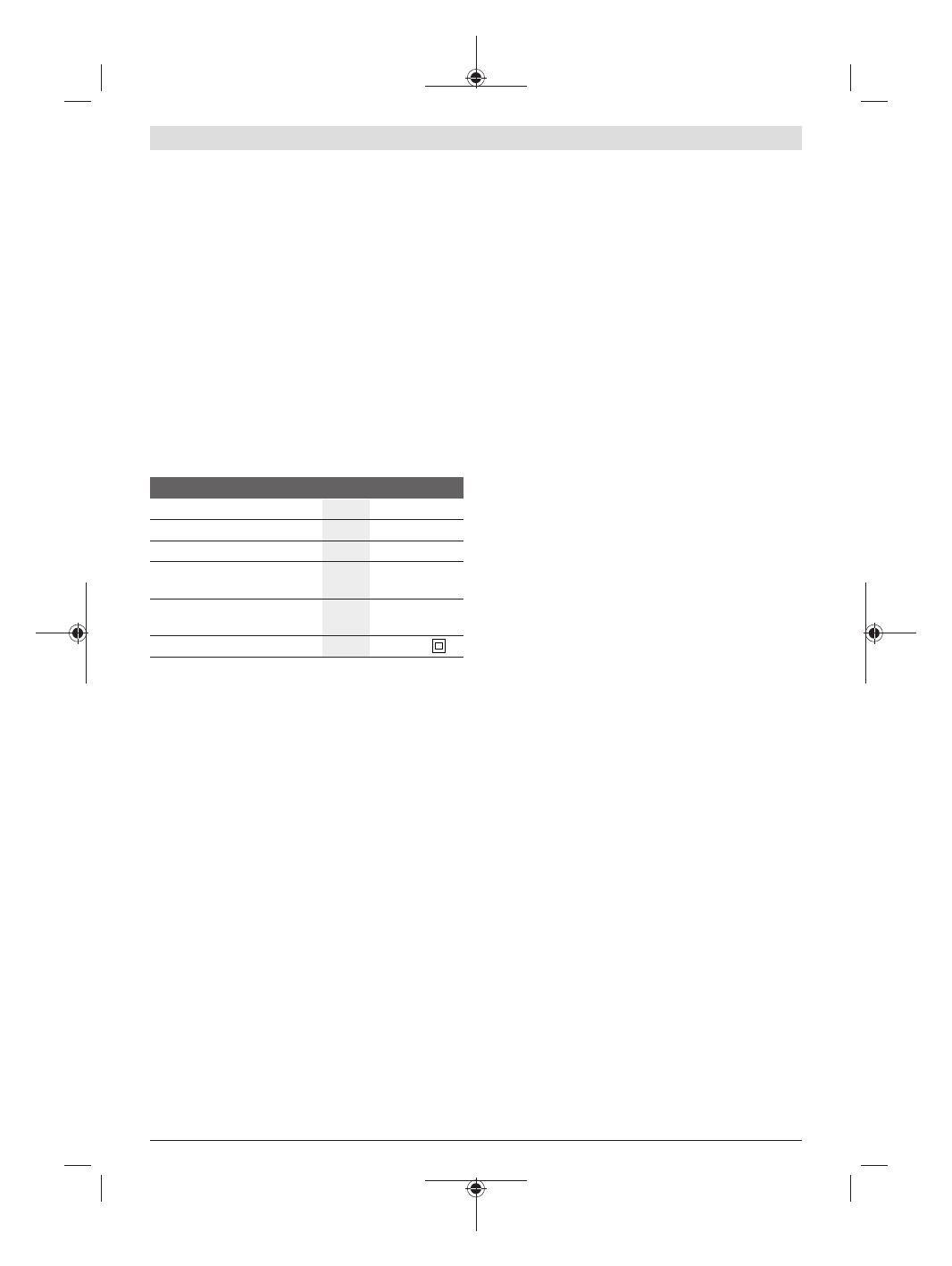

Technical data

Router

GKF 550/GKF 5-6

Article number

3 601 FA0 0..

Rated power input

W

550

No-load speed

rpm

33000

Tool holder

mm

inches

6

¼

Weight according to

EPTA-Pro-cedure 01:2014

kg

1.4

Protection class

/ II

The specifications apply to a rated voltage [U] of 230 V. These spe-

cifications may vary at different voltages and in country-specific mod-

els.

Noise/Vibration Information

Noise emission values determined according to

EN 60745-2-17

.

Typically, the A-weighted noise level of the power tool is:

83

dB(A); sound power level

94

dB(A).

Uncertainty K =

3

dB.

Wear hearing protection!

Total vibration values a

h

(triax vector sum) and uncertainty K

determined according to

EN 60745-2-17

(no load):

a

h

=

3.0

m/s

2

, K=

1.5

m/s

2

.

The vibration level given in these instructions has been

measured in accordance with a standardised measuring pro-

cedure and may be used to compare power tools. It can also

be used for a preliminary estimation of exposure to vibra-

tion.

The stated vibration level applies to the main applications of

the power tool. However, if the power tool is used for differ-

ent applications, with different application tools or poorly

maintained, the vibration level may differ. This can signific-

antly increase the exposure to vibration over the total work-

ing period.

To estimate the exposure to vibration accurately, the times

when the tool is switched off or when it is running but not ac-

tually being used should also be taken into account. This can

significantly reduce the exposure to vibration over the total

working period.

Implement additional safety measures to protect the oper-

ator from the effects of vibration, such as servicing the

power tool and application tools, keeping the hands warm,

and organising workflows correctly.

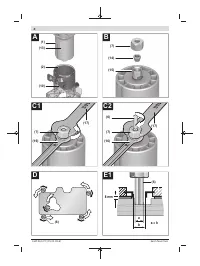

Fitting

Changing the tool

u

Pull the plug out of the socket before carrying out any

work on the power tool.

u

Wearing protective gloves while fitting and changing

router bits is recommended.

Removing the routing base (see figure A)

Before fitting a router bit, you must first separate the routing

base

(2)

from the drive unit

(1)

.

Open the wing bolt

(11)

on the routing base

(2)

.

Pull the drive unit out in an upward direction.

Changing the collet (see figure B)

Depending on the router bit used, you may have to change

the tightening nut with the collet

(14)

before fitting the

router bit.

If the correct collet for your router bit is already fitted,

please follow the work steps in the following section on (see

"Fitting the router bit (see figure

The collet

(14)

must sit in the tightening nut with a small

amount of play. The tightening nut

(7)

must be easy to fit. If

the tightening nut or collet is damaged, replace it immedi-

ately.

Place the open-end spanner

(16)

on the tool holder

(15)

(see figure

C1

).

Unscrew the tightening nut

(7)

in an anti-clockwise direction

using the open-end spanner

(17)

.

If required, clean all the parts you want to fit with a soft

brush or by blowing them clean with compressed air before

assembling them.

Place the new tightening nut onto the tool holder

(15)

.

Loosely tighten the tightening nut.

u

Do not, under any circumstances, tighten the collet

with the tightening nut until a router bit has been fit-

ted.

The collet may otherwise become damaged.

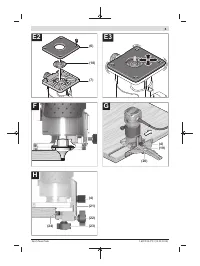

Fitting the router bit (see figure C1 – C2)

Router bits are available in a wide variety of designs and

qualities depending on the intended application.

Router bits made of high-performance high-speed steel

(HSS)

are suited to machining soft materials such as soft-

wood and plastic.

Router bits with carbide tips (HM)

are especially suitable

for hard and abrasive materials such as hardwood and alu-

minium.

Original router bits from the extensive range of Bosch ac-

cessories are available from your specialist dealer.

English |

13

Bosch Power Tools

1 609 92A 47Z | (05.04.2018)

Характеристики

Остались вопросы?Не нашли свой ответ в руководстве или возникли другие проблемы? Задайте свой вопрос в форме ниже с подробным описанием вашей ситуации, чтобы другие люди и специалисты смогли дать на него ответ. Если вы знаете как решить проблему другого человека, пожалуйста, подскажите ему :)