Дрели P.I.T. PSB16-C - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

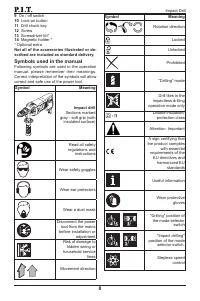

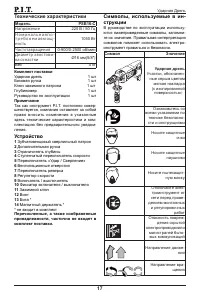

Impact Drill

10

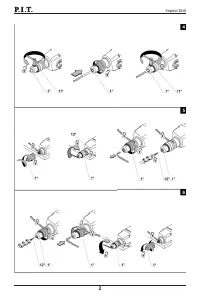

Impact drilling:

To switch to this operation mode, turn

switch

5

so that the Impact drilling

sign coincides with the mark on the

body.

One can switch to another operation mode

without stopping the power tool, simply

decrease pressure applied to it to some

extent.

Stepless speed adjustment

Speed is controlled from O to max-

imum by pressing force of on / off

switch

9

. Weak pressing results in

low revolutions, which enable a smooth power

tool switch-on.

Speed selector thumbwheel

Use speed control

8

to set required revolu-

tions and impact frequency.

► Push on / off switch

9

and lock it in the po-

sition with lock-on button

10

.

► Set the needed speed.

The required speed is dependent on the ma-

terial and can be determined with practical

trials. When operating your power tool at a

low speed for a long time, it has to be cooled

down for 3 minutes. To do it, set a maximum

speed and leave your power tool to run idle.

Step speed selector switch

Attention: one can only change

the revolutions per minute range

after the engine fully stops.

The first speed

- you can find the

values of the revolutions per minute

range in the technical specifi cations

table.

The second speed

- you can find

the values of the revolutions per

minute range in the technical speci-

fi cations table.

Changing the rotational directions

Change the direction of rotation

only & after a full stop of the mo-

tor, acting otherwise may cause

damage to the power tool.

Rotation to the right (drilling, screwing in)

-

move the rotational direction switch

7

to the

right.

Rotation to the left (unscrewing) -

move the

rotational direction switch

7

to the left.

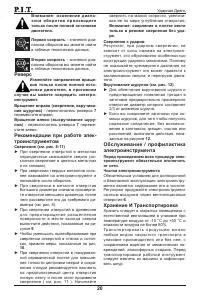

Recommendations on the power

tool operation

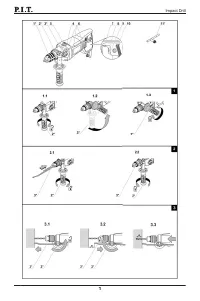

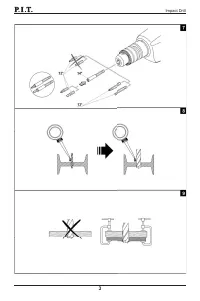

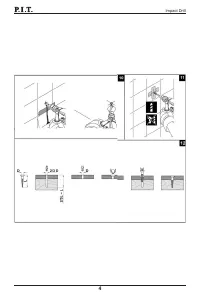

Drilling (see fi g. 8-11)

► Grease the drill bit regularly when drilling

holes in metals (except drilling non-ferrous

metals and their alloys).

► When drilling hard metals, apply more

force to the power tool and lower the rota-

tion speed.

► When drilling large diameter holes in met-

al, fi rst drill a hole with a smaller diameter

and ream it till the necessary diameter (see

fi g. 8).

► In order to avoid splitting of the surface at

an exit point of a drill bit when drilling holes

in wood, follow the instructions shown in

fi gure 9.

► In order to decrease dust production when

drilling holes in walls and ceilings, take ac-

tions indicated in fi g. 10.

► When drilling holes in glazed ceramic tiles,

in order to improve the drill centering accu-

racy and to save the glaze from damage,

apply adhesive tape to the presumed hole

center and drill after that (see fig. 11 ).

Start drilling at lower speed increasing it as

the hole deepens.

Caution: drill tiles in

the impactless drilling operation mode

only.

Impact drilling

During the impact drilling, the result does not

depend on the pressure applied to the power

tool this is caused due to the peculiarities in

the impact mechanism design. That is why

you should not apply excessive pressure to

the power tool it can jam the drill and overload

the engine.

Screwing the screws (see fi g. 12)

► To make fastening of screws easier and in

order to prevent cracking of the work piec-

es, fi rst drill a hole with a diameter equal to

2/3 of a diameter of the screw.

► If you are connecting work pieces with the

help of screws, in order to achieve durable

joint without getting cracks, fracturing or

layering, take actions shown in fi gure 12 .

Power tool maintenance / preven-

tive measures

Before carrying out any works on the pow-

er tool it must be disconnected from the

mains.

Cleaning of the power tool

An indispensable condition for a safe long-

term exploitation of the power tool is to keep

it clean. Regularly flush the power tool with

compressed air thought the ventilation slots

6

.

Transportation of the power tools

► Categorically not to drop any mechanical

impact on the packaging during transport.

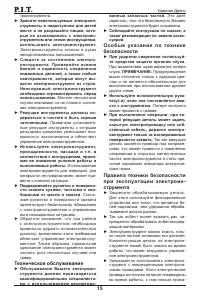

Характеристики

Остались вопросы?Не нашли свой ответ в руководстве или возникли другие проблемы? Задайте свой вопрос в форме ниже с подробным описанием вашей ситуации, чтобы другие люди и специалисты смогли дать на него ответ. Если вы знаете как решить проблему другого человека, пожалуйста, подскажите ему :)