Шуруповерты Ingersoll Rand 7803RAKC - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

04580452_ed6

EN-1

EN

Product Safety Information

Intended Use:

These Drills are designed for drilling, valve guide reaming and cylinder honing operations in the

automotive industry.

For additional information refer to Product Safety Information Manual Form 04580353.

Manuals can be downloaded from ingersollrandproducts.com

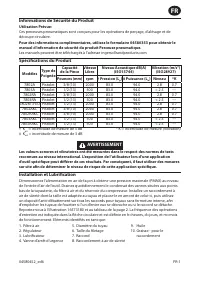

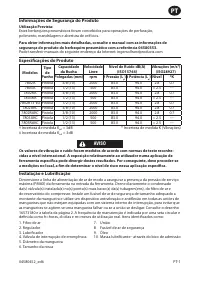

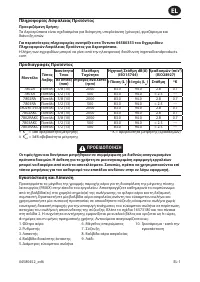

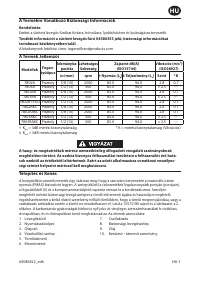

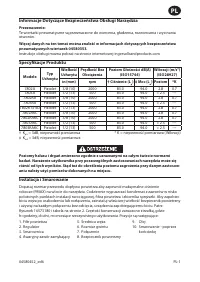

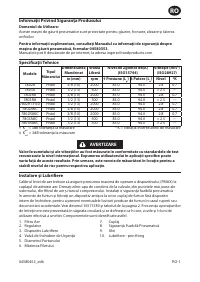

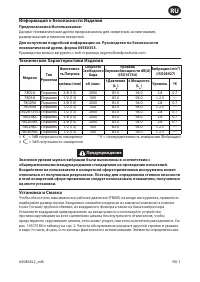

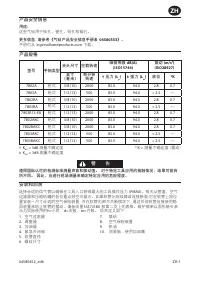

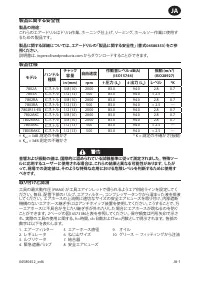

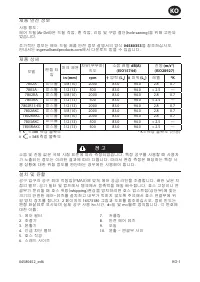

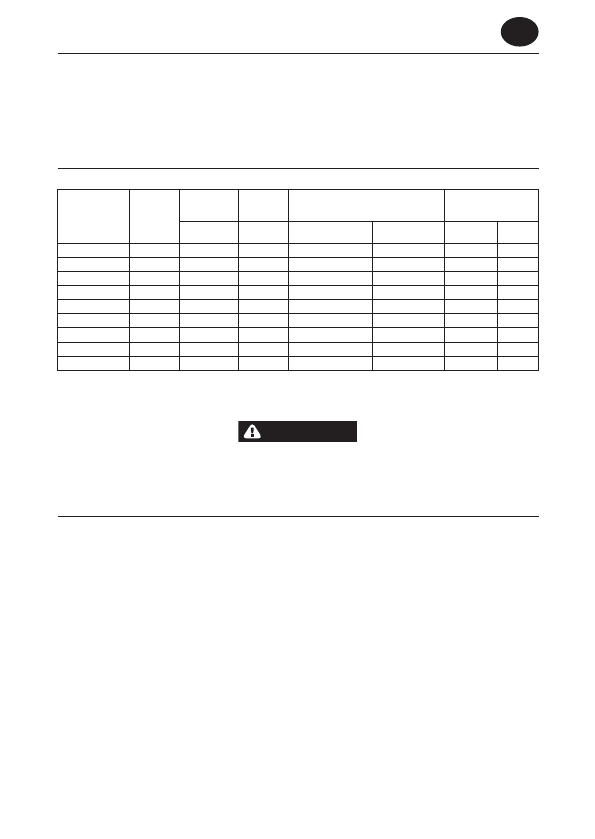

Product Specifications

Models

Type of

Handle

Chuck

Capacity

Free

Speed

Sound Level dB(A)

(ISO15744)

Vibration (m/s²)

(ISO28927)

in (mm)

rpm

† Pressure (L

p

) ‡ Power (L

w

)

Level

*K

7802A

Pistol

3/8 (10)

2000

83.0

94.0

2.8

0.7

7803A

Pistol

1/2 (13)

500

83.0

94.0

< 2.5

---

7802RA

Pistol

3/8 (10)

2000

83.0

94.0

2.8

0.7

7803RA

Pistol

1/2 (13)

500

83.0

94.0

< 2.5

---

7802R13-EU

Pistol

1/2 (13)

2000

83.0

94.0

2.8

0.7

7802AKC

Pistol

3/8 (10)

2000

83.0

94.0

2.8

0.7

7802RAKC

Pistol

3/8 (10)

2000

83.0

94.0

2.8

0.7

7803AKC

Pistol

1/2 (13)

500

83.0

94.0

< 2.5

---

7803RAKC

Pistol

1/2 (13)

500

83.0

94.0

< 2.5

---

† K

pA

= 3dB measurement uncertainty

‡ K

wA

= 3dB measurement uncertainty

* K = Vibration measurement uncertainty

WARNING

Sound and vibration values were measured in compliance with internationally recognized

test standards. The exposure to the user in a specific tool application may vary from these

results. Therefore, on site measurements should be used to determine the hazard level in

that specific application.

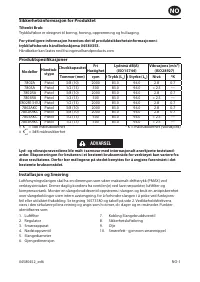

Installation and Lubrication

Size air supply line to ensure tool’s maximum operating pressure (PMAX) at tool inlet. Drain

condensate from valve(s) at low point(s) of piping, air filter and compressor tank daily. Install a

properly sized Safety Air Fuse upstream of hose and use an anti-whip device across any hose

coupling without internal shut-off, to prevent hose whipping if a hose fails or coupling

disconnects. See drawing 16573180 and table on page 2. Maintenance frequency is shown in a

circular arrow and defined as h=hours, d=days, and m=months of actual use. Items identified as:

1. Air filter

6. Thread size

2. Regulator

7. Coupling

3. Lubricator

8. Safety Air Fuse

4. Emergency shut-off valve

9. Oil

5. Hose diameter

10. Grease - through fitting