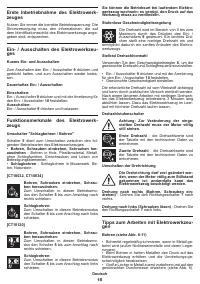

Шуруповерты CROWN CT10034 - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

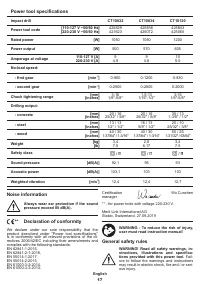

22

English

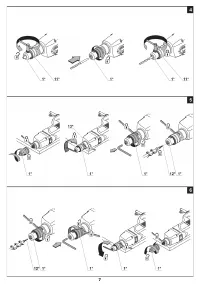

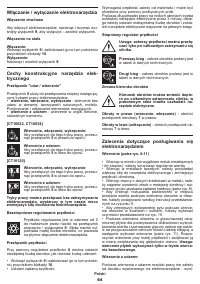

Impact drilling:

To switch to this operation mode, turn

switch

5

so that the Impact drilling sign coin-

cides with the mark on the body�

[CT10120]

Drilling, screwing, unscrewing:

To switch to this operation mode, move

switch

5

right to the stop�

Impact drilling:

To switch to this operation mode, move

switch

5

left to the stop�

One can switch to another operation mode without

stopping the power tool, simply decrease pressure

applied to it to some extent.

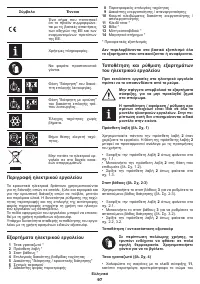

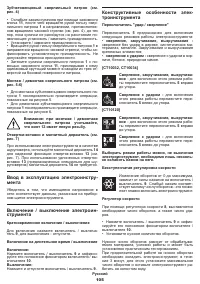

Stepless speed adjustment

Speed is controlled from 0 to maximum by

pressing force of on / off switch

9

� Weak

pressing results in low revolutions, which

enable a smooth power tool switch-on�

Speed selector thumbwheel

Use speed control

8

to set required revolutions and

impact frequency�

•

Push on / off switch

9

and lock it in the position with

lock-on button

10

�

•

Set the needed speed�

The required speed is dependent on the material and

can be determined with practical trials�

When operating your power tool at a low speed for a long

time, it has to be cooled down for 3 minutes� To do it, set

a maximum speed and leave your power tool to run idle�

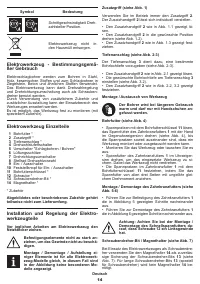

Step speed selector switch

Attention: one can only change the revo

-

lutions per minute range after the engine

fully stops.

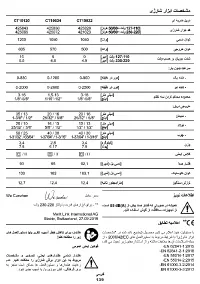

The first speed

- you can find the values of

the revolutions per minute range in the tech-

nical specifications table.

The second speed

- you can find the val

-

ues of the revolutions per minute range in

the technical specifications table.

Changing the rotational directions

Change the direction of rotation only

after a full stop of the motor, acting oth

-

erwise may cause damage to the power

tool.

Rotation to the right (drilling, screwing in)

- move

the rotational direction switch

7

to the right�

Rotation to the left (unscrewing)

- move the rota-

tional direction switch

7

to the left�

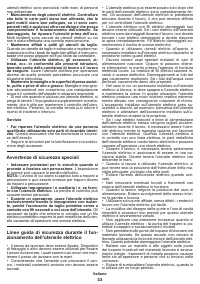

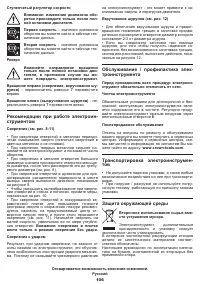

Recommendations on the power tool

operation

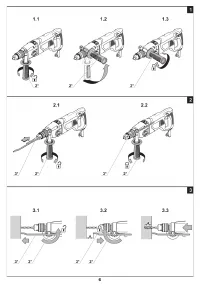

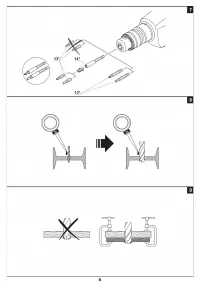

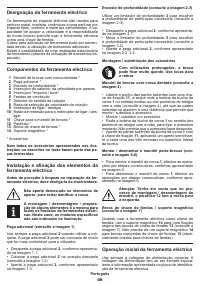

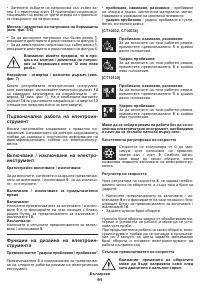

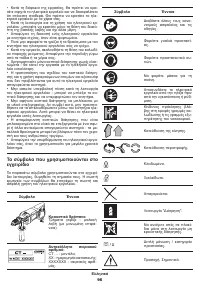

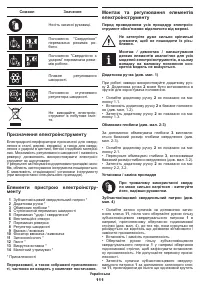

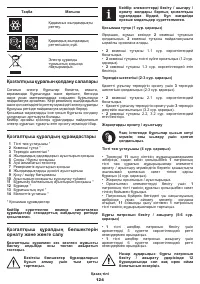

Drilling (see fig. 8-11)

•

Grease the drill bit regularly when drilling holes in

metals (except drilling non-ferrous metals and their al-

loys)�

•

When drilling hard metals, apply more force to the

power tool and lower the rotation speed�

•

When drilling large diameter holes in metal, first drill

a hole with a smaller diameter and ream it till the nec-

essary diameter (see fig. 8).

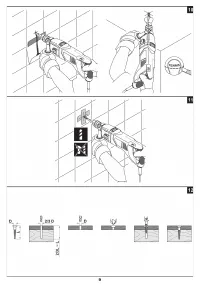

•

In order to avoid splitting of the surface at an exit

point of a drill bit when drilling holes in wood, follow the

instructions shown in figure 9.

•

In order to decrease dust production when drilling

holes in walls and ceilings, take actions indicated in

fig. 10.

•

When drilling holes in glazed ceramic tiles, in order

to improve the drill centering accuracy and to save the

glaze from damage, apply adhesive tape to the pre-

sumed hole center and drill after that (see fig. 11). Start

drilling at lower speed increasing it as the hole deep-

ens�

Caution: drill tiles in the impactless drilling

operation mode only.

Impact drilling

During the impact drilling, the result does not depend

on the pressure applied to the power tool - this is

caused due to the peculiarities in the impact mecha-

nism design� That is why you should not apply exces-

sive pressure to the power tool - it can jam the drill and

overload the engine�

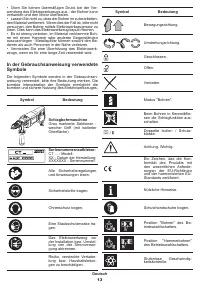

Screwing the screws (see fig. 12)

•

To make fastening of screws easier and in order

to prevent cracking of the work pieces, first drill a

hole with a diameter equal to 2/3 of a diameter of the

screw�

•

If you are connecting work pieces with the help of

screws, in order to achieve durable joint without get-

ting cracks, fracturing or layering, take actions shown

in figure 12.

Power tool maintenance / preventive

measures

Before carrying out any works on the power tool it

must be disconnected from the mains

�

Cleaning of the power tool

An indispensable condition for a safe long-term exploi-

tation of the power tool is to keep it clean� Regularly

flush the power tool with compressed air thought the

ventilation slots

6

�

After-sales service and application service

Our after-sales service responds to your questions

concerning maintenance and repair of your product as

5