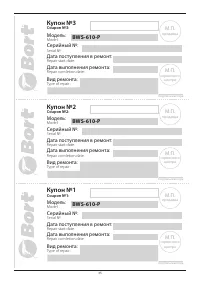

Шлифмашины Bort BWS-610-P - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

12

• Use special care when working corners, sharp edges, etc.

Avoid bouncing and snagging the accessory. Corners,

sharp edges or bouncing have a tendency to snag the

rotating accessory and cause loss of control or kickback.

• Do not attach a saw chain woodcarving blade or

toothed saw blade. Such blades create frequent kick-

back and loss of control.

Safety warnings specific for Grinding

and Abrasive Cutting-Off operations

• Use only wheel types that are recommended for your

power tool and the specific guard designed for the se-

lected wheel. Wheels for which the power tool was not

designed cannot be adequately guarded and are unsafe.

• The grinding surface of the centre depressed wheels

must be mounted below the plane of the guard lip. An

improperly mounted wheel that projects through the

plane of the guard lip cannot be adequately protected.

• The guard must be securely attached to the power tool

and positioned for maximum safety, so the least amount

of wheel is exposed towards the operator. The guard

helps to protect operator from broken wheel fragments,

accidental contact with wheel and sparks that could

ignite clothing.

• Wheels must be used only for recommended applica-

tions. For example: do not grind with the side of the

cut-off wheel. Abrasive cut-off wheels are intended for

peripheral grinding; side forces applied to these wheels

may cause them to shatter.

• Always use undamaged wheel flanges that are of correct

size and shape for your selected wheel. Proper wheel

flanges support the wheel thus reducing the possibility

of wheel breakage. Flanges for cut-off wheels may be

different from grinding wheel flanges.

• Do not use worn down reinforced wheels from larger

power tools. Wheels intended for larger power tools are

not suitable for the higher speed of a smaller tool and

may burst.

Additional safety warnings specific for abrasive

cutting off operations

• Do not “jam” the cut-off wheel or apply excessive pres-

sure. Do not attempt to make an excessive depth of cut.

Overstressing the wheel increases the loading and sus-

ceptibility to twisting or binding of the wheel in the cut

and the possibility of kickback or wheel breakage.

• Do not position your body in line with and behind the

rotating wheel. When the wheel, at the point of opera-

tion, is moving away from your body, the possible kick-

back may propel the spinning wheel and the power tool

directly at you.

• When wheel is binding or when interrupting a cut for

any reason, switch off the power tool and hold the pow-

er tool motionless until the wheel comes to a complete

stop. Never attempt to remove the cut-off wheel from

the cut while the wheel is in motion otherwise kickback

may occur. Investigate and take corrective action to

eliminate the cause of wheel binding.

• Do not restart the cutting operation in the workpiece.

Let the wheel reach full speed and carefully re-enter

the cut. The wheel may bind, walk up or kickback if the

power tool is restarted in the workpiece.

• Support panels or any oversized workpiece to minimize

the risk of wheel pinching and kickback. Large work-

pieces tend to sag under their own weight. Supports

must be placed under the workpiece near the line of

cut and near the edge of the workpiece on both sides

of the wheel.

• Use extra caution when making a “pocket cut” into exist-

ing walls or other blind areas. The protruding wheel may

cut gas or water pipes, electrical wiring or objects that

can cause kickback.

Safety warnings specific for sanding operations

• Do not use excessively oversized sanding disc paper. Fol-

low manufacturers recommendations, when selecting

sanding paper. Larger sanding paper extending beyond

the sanding pad presents a laceration hazard and may

cause snagging, tearing of the disc, or kickback.

Safety warnings specific for wire brushing

operations

• Be aware that wire bristles are thrown by the brush even

during ordinary operation. Do not overstress the wires

by applying excessive load to the brush. The wire bristles

can easily penetrate light clothing and/or skin.

• If the use of a guard is recommended for wire brushing,

do not allow any interference of the wire wheel or brush

with the guard. Wire wheel or brush may expand in

diameter due to work load and centrifugal forces.

Additional safety warnings

• Wear safety goggles.

• Use suitable detectors to determine if utility lines are

hidden in the work area or call the local utility company

for assistance. Contact with electric lines can lead to

fire and electric shock. Damaging a gas line can lead

to explosion. Penetrating a water line causes property

damage or may cause an electric shock.

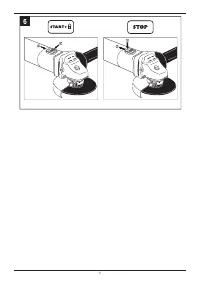

• Release the On/Off switch and set it to the off position

when the power supply is interrupted, e. g., in case of

a power failure or when the mains plug is pulled. This

prevents uncontrolled restarting.

• Do not touch grinding and cutting discs before they

have cooled down. The discs can become very hot while

working.

• Secure the workpiece. A workpiece clamped with

clamping devices or in a vice is held more secure than

by hand.

MAINTENANCE AND CLEANING

Make sure that the machine is not live when carry-

ing out maintenance work on the motor.

• Regularly clean the machine housing with a soft cloth,

preferably after each use. Keep the ventilation slots free

from dust and dirt.If the dirt does not come off use a soft

cloth moistened with soapy water. Never use solvents

such as petrol, alcohol, ammonia water, etc. These sol-

vents may damage the plastic parts.

• The machine requires no additional lubrication.

• Should a fault occur, e.g. after wear of a part, please

contact your local BORT GLOBAL LIMITED dealer.

Характеристики

Остались вопросы?Не нашли свой ответ в руководстве или возникли другие проблемы? Задайте свой вопрос в форме ниже с подробным описанием вашей ситуации, чтобы другие люди и специалисты смогли дать на него ответ. Если вы знаете как решить проблему другого человека, пожалуйста, подскажите ему :)