Лобзики BORT BPS-900X-QLt - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

8

not allow persons unfamiliar with the power tool or these

instructions to operate the power tool . Power tools are

dangerous in the hands of untrained users .

• Maintain power tools . Check for misalignment or bind-

ing of moving parts, breakage of parts and any other

condition that may affect the power tool’s operation . If

damaged, have the power tool repaired before use . Many

accidents are caused by poorly maintained power tools .

• Keep cutting tools sharp and clean . Properly maintained

cutting tools with sharp cutting edges are less likely to

bind and are easier to control .

• Use the power tool, accessories and tool bits etc . in ac-

cordance with these instructions, taking into account the

working conditions and the work to be performed . Use

of the power tool for operations different from those in-

tended could result in a hazardous situation .

Service

Have your power tool serviced by a qualified repair person

using only identical replacement parts . This will ensure that

the safety of the power tool is maintained .

SAFETY WARNINGS FOR JIGSAWS

• Keep hands away from the sawing range . Do not reach

under the workpiece . Contact with the saw blade can

lead to injuries .

• Apply the machine to the workpiece only when switched

on . Otherwise there is danger of kickback when the cut-

ting tool jams in the workpiece .

• Pay attention that the base plate securely on the material

while sawing . A jammed saw blade can break or lead to

kickback .

• When the cut is completed, switch off the machine and

then pull the saw blade out of the cut only after it has

come to a standstill . In this manner you can avoid kick-

back and can place down the machine securely .

• Use only undamaged saw blades that are in perfect con-

dition . Bent or dull saw blades can break, negatively in-

fluence the cut, or lead to kickback .

• Do not brake the saw blade to a stop by applying side

pressure after switching off . The saw blade can be dam-

aged, break or cause kickback .

• Use suitable detectors to determine if utility lines are hid-

den in the work area or call the local utility company for

assistance . Contact with electric lines can lead to fire and

electric shock . Damaging a gas line can lead to explosion .

Penetrating a water line causes property damage or may

cause an electric shock .

• Secure the workpiece . A workpiece clamped with clamp-

ing devices or in a vice is held more secure than by hand .

• Always wait until the machine has come to a complete

stop before placing it down . The tool insert can jam and

lead to loss of control over the power tool .

• Before any work on the machine itself, pull the mains

plug .

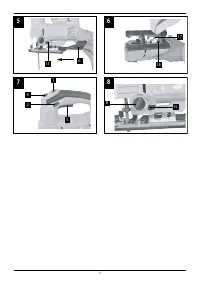

• Clean the shank of the saw blade before inserting it . An

unclean shank cannot be fastened securely .

• Check the tight seating of the saw blade . A loose saw

blade can fall out and lead to injuries .

• The saw blade should not be longer than required for the

intended cut . Use a narrow saw blade when sawing tight

curves .

• If the saw blade is wedged or jammed when removing,

press the saw blade holder lightly toward the front (ap-

prox . 2 mm) .

• Dusts from materials such as lead-containing coatings,

some wood types, minerals and metal can be harmful to

one’s health and cause allergic reactions, lead to respira-

tory infections and/or cancer . Materials containing asbes-

tos may only be worked by specialists .

• As far as possible, use a dust extraction system suitable

for the material .

• Provide for good ventilation of the working place .

• It is recommended to wear a P2 filter-class respirator .

• Observe the relevant regulations in your country for the

materials to be worked .

• Prevent dust accumulation at the workplace . Dusts can

easily ignite .

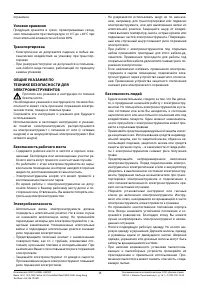

• Observe correct mains voltage! The voltage of the power

source must agree with the voltage specified on the

nameplate of the machine . Power tools marked with 230

V can also be operated with 220 V .

• To save energy, only switch the power tool on when us-

ing it .

• The contact protector attached to the casing prevents

accidental touching of the saw blade during the working

procedure and may not be removed .

• Before sawing in wood, particle boards, building materi-

als etc ., check for foreign objects, such as nails, screws,

etc . and remove them as required .

• Plunge cuts may only be applied to soft materials, such

as wood, gypsum board, etc . For plunge cuts, use only

short saw blades .

• The sliding shoe can prevent the surface from being

scratched . The splinter guard can prevent fraying of the

surface while sawing wood . Do not use the splinter guard

for mitre cuts .

• Adapt the settings of your power tool to the respective

application . For example, reduce the stroke rate and or-

bital action when cutting metal or for tight curved cuts .

• For long and straight cuts in thick wood (>40 mm), the

cutting line can become inaccurate . In this case, using a

circular saw is recommended to achieve accurate cuts .

• In extreme conditions, always use dust extraction as far

as possible . Blow out ventilation slots frequently and

install a portable residual current device (PRCD) . When

working metals, conductive dust can settle in the interior

of the power tool . The total insulation of the power tool

can be impaired .

MAINTENANCE AND CLEANING

Make sure that the machine is not live when carrying

out maintenance work on the motor .

•

Regularly clean the machine housing with a

soft cloth, preferably after each use . Keep the ventilation

slots free from dust and dirt .If the dirt does not come

off use a soft cloth moistened with soapy water . Never

use solvents such as petrol, alcohol, ammonia water, etc .

These solvents may damage the plastic parts .

• Lubricate the guide roller occasionally with a drop of oil .

• Should a fault occur, e .g . after wear of a part, please con-

tact your local BORT GLOBAL LIMITED dealer .

DISPOSAL

Характеристики

Остались вопросы?Не нашли свой ответ в руководстве или возникли другие проблемы? Задайте свой вопрос в форме ниже с подробным описанием вашей ситуации, чтобы другие люди и специалисты смогли дать на него ответ. Если вы знаете как решить проблему другого человека, пожалуйста, подскажите ему :)