Кондиционеры Tesla TA53FFUL - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

48

ENG

use any sources of ignition in such a manner that it may lead to the risk of fire or explosion. All possible ignition

sources, including cigarette smoking, should be kept sufficiently far away from the site of installation, repairing,

removing and disposal, during which refrigerant can possibly be released to the surrounding space. Prior to

work taking place, the area around the equipment is to be surveyed to make sure that there are no flammable

hazards or ignition risks.

‘No Smoking’ signs shall be displayed.

5. Ventilated Area(open the door and window):

Ensure that the area is in the open or that it is adequately ventilated before breaking into the system or

conducting any hot work. A degree of ventilation shall continue during the period that the work is carried

out. The ventilation should safely disperse any released refrigerant and preferably expel it externally into the

atmosphere.

6. Checks to the refrigeration equipment:

Where electrical components are being changed, they shall be fit for the purpose and to the correct

specification. At all times the manufacturer’s maintenance and service guidelines shall be followed. If in doubt,

consult the manufacturer’s technical department for assistance. The following checks shall be applied to

installations using flammable refrigerants:

• The charge size is in accordance with the room size within which the refrigerant containing parts are installed.

• The ventilation machinery and outlets are operating adequately and are not obstructed.

• If an indirect refrigerating circuit is being used, the secondary circuit shall be checked for the presence of

refrigerant.

• Refrigeration pipe or components are installed in a position where they are unlikely to be exposed to any

substance which may corrode refrigerant containing components, unless the components are constructed of

materials which are inherently resistant to being corroded or are suitably protected against being so corroded.

7. Checks to electrical devices:

Repair and maintenance to electrical components shall include initial safety checks and component inspection

procedures. If a fault exists that could compromise safety, then no electrical supply shall be connected to the

circuit until it is satisfactorily dealt with. If the fault cannot be corrected immediately but it is necessary to continue

operation, an adequate temporary solution shall be used. This shall be reported to the owner of the equipment

so all parties are advised.

Initial safety checks shall include:

• That capacitors are discharged: this shall be done in a safe manner to avoid possibility of sparking.

• That no live electrical components and wiring are exposed while charging, recovering or purging the system.

• Keep continuity of earthing.

Inspection of Cable

Leakage check of R32 refrigerant

Check the cable for wear, corrosion, overvoltage, vibration and check if there are sharp edges and other adverse

effects in the surrounding environment. During the inspection, the impact of aging or the continuous vibration of

the compressor and the fan on it should be taken into consideration.

Note

: Check the leakage of the refrigerant in an environment where there is no potential ignition source. No

halogen probe (or any other detector that uses an open flame) should be used.

Leak detection method

:

For systems with refrigerant R32, electronic leak detection instrument is available to detect and leak detection

should not be conducted in environment with refrigerant. Make sure the leak detector will not become a potential

source of ignition, and is applicable to the measured refrigerant. Leak detector shall be set for the minimum

ignitable fuel concentration (percentage) of the refrigerant. Calibrate and adjust to proper gas concentration (no

more than 25%) with the used refrigerant.

The fluid used in leak detection is applicable to most refrigerants. But do not use chloride solvents to prevent the

reaction between chlorine and refrigerants and the corrosion of copper pipeline.

If you suspect a leak, then remove all the fire from the scene or put out the fire.

If the location of the leak needs to be welded, then all refrigerants need to be recovered, or, isolate all refrigerants

away from the leak site (using cut-off valve). Before and during the welding, use OFN to purify the entire system.

Содержание

- 3 ВНИМАНИЕ

- 5 ПРЕДУПРЕЖДЕНИЯ ПО ИСПОЛЬЗОВАНИЮ; Состояния при которых система будет работать неисправно

- 6 Примечания по обогреву

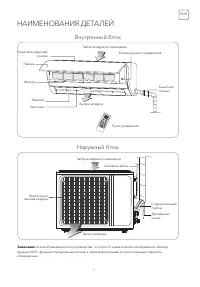

- 7 НАИМЕНОВАНИЯ ДЕТАЛЕЙ; Внутренний блок

- 8 Очистите панель; ЧИСТКА И УХОД

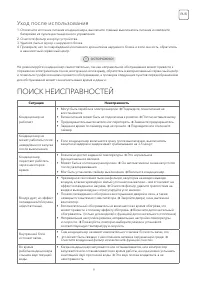

- 9 Уход после использования; ПОИСК НЕИСПРАВНОСТЕЙ

- 10 ЗАМЕЧАНИЯ ПО УСТАНОВКЕ; Осмотр при распаковке

- 11 Правила безопасности при установке кондиционера

- 12 Требования к работе на высоте

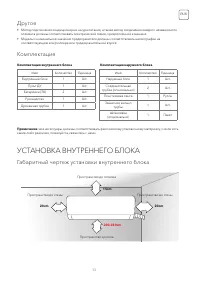

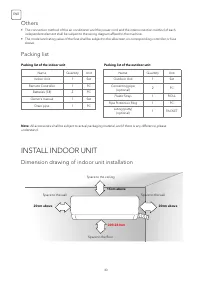

- 13 Другое; УСТАНОВКА ВНУТРЕННЕГО БЛОКА; Габаритный чертеж установки внутреннего блока

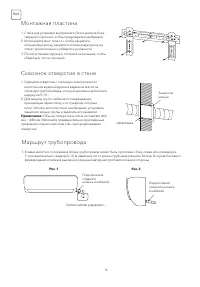

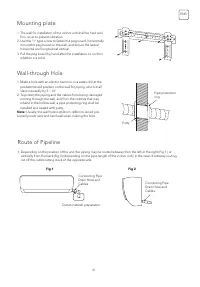

- 14 Монтажная пластина

- 15 Соединение сливной трубы; Крепление внутреннего блока

- 16 Схема подключения

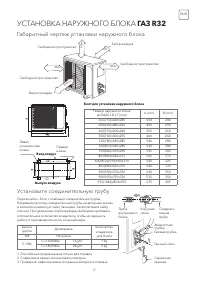

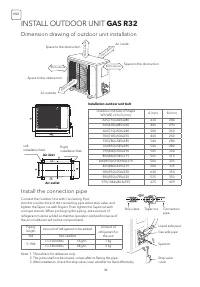

- 17 УСТАНОВКА НАРУЖНОГО БЛОКА; Габаритный чертеж установки наружного блока

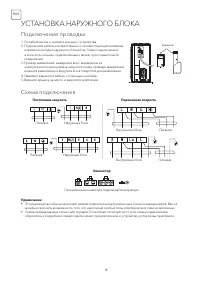

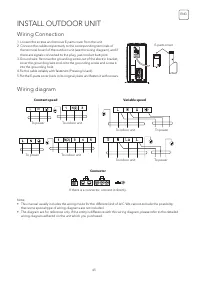

- 18 Подключение проводки

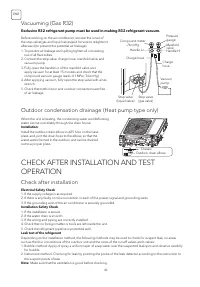

- 19 Проверка после установки

- 20 Пробная эксплуатация; ТЕХНИЧЕСКОЕ ОБСЛУЖИВАНИЕ; Осмотр площадки

- 21 Рабочие процедуры

- 22 Осмотр кабеля; Удаление воздуха; Порядок заправки хладагентов

- 23 Утилизация и восстановление

- 25 Описание кнопок

- 28 Использование

Характеристики

Остались вопросы?Не нашли свой ответ в руководстве или возникли другие проблемы? Задайте свой вопрос в форме ниже с подробным описанием вашей ситуации, чтобы другие люди и специалисты смогли дать на него ответ. Если вы знаете как решить проблему другого человека, пожалуйста, подскажите ему :)