Гайковерты Bosch GDX 18V-200 C (06019G4201) - инструкция пользователя по применению, эксплуатации и установке на русском языке. Мы надеемся, она поможет вам решить возникшие у вас вопросы при эксплуатации техники.

Если остались вопросы, задайте их в комментариях после инструкции.

"Загружаем инструкцию", означает, что нужно подождать пока файл загрузится и можно будет его читать онлайн. Некоторые инструкции очень большие и время их появления зависит от вашей скорости интернета.

English |

17

Using other batteries can lead to injuries and pose a fire

hazard.

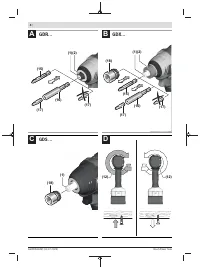

Set the rotational direction switch

(12)

to the middle posi-

tion to avoid unintentionally switching it on. Insert the

charged battery

(6)

into the handle until you feel it engage

and it is flush with the handle.

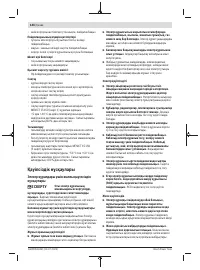

Set the rotational direction (see figure D)

The rotational direction switch

(12)

is used to change the ro-

tational direction of the power tool. However, this is not pos-

sible while the on/off switch

(13)

is being pressed.

Right rotation:

To drive in screws and tighten nuts, press

the rotational direction switch

(12)

through to the left stop.

Left Rotation:

To loosen and unscrew screws and nuts,

press the rotational direction switch

(12)

through to the

right stop.

Switching on/off

To

start

the power tool, press and hold the on/off switch

(13)

.

To

switch off

the power tool, release the on/off switch

(13)

.

Preselecting the speed/impact rate

With the button

(8)

, you can preselect the required speed/

impact rate in three stages. Press the button

(8)

repeatedly

until the desired setting appears in the speed indicator

(11)

.

The selected setting will be saved.

The required speed/impact rate is dependent on the mater-

ial and the work conditions and can be determined by prac-

tical trials.

Adjusting the Speed

You can adjust the speed of the power tool when it is on by

pressing in the on/off switch

(13)

to varying extents.

A light pressure on the on/off switch

(13)

results in a low ro-

tational speed. Increased pressure on the switch causes an

increase in speed.

Switching the "PowerLight" lamp on/off

Press the button

(10)

to

activate

the lamp

(9)

. To switch off

the lamp

(9)

, press the button

(10)

again.

Practical advice

u

Only apply the power tool to the screw/nut when the

tool is switched off.

Rotating tool inserts can slip off.

The torque depends on the impact duration. The maximum

achieved torque results from the sum of all individual

torques achieved through impact. Maximum torque is

achieved after an impact duration of 6–10 seconds. After

this duration, the tightening torque is increased only minim-

ally.

The impact duration is to be determined for each required

tightening torque. The actually achieved tightening torque is

always to be checked with a torque wrench.

Screw applications with hard, spring-loaded or soft seats

When the achieved torques in an impact series are measured

during a test and transferred into a diagram, the result is the

curve of a torque characteristic. The height of the curve cor-

responds with the maximum reachable torque, and the

steepness indicates the duration in which this is achieved.

A torque gradient depends on the following factors:

– Strength properties of the screws/nuts

– Type of backing (washer, disc spring, seal)

– Strength properties of the material being screwed/bolted

together

– Lubrication conditions at the screw/bolt connection

The following application cases result accordingly:

– A

hard seat

is a metal-to-metal screw application which

uses washers. After a relatively short impact duration, the

maximum torque is reached (steep characteristic curve).

Unnecessary long impact duration only causes damage to

the machine.

– A

spring-loaded seat

is also a metal-to-metal screw ap-

plication but uses spring washers, disc springs, studs or

screws/nuts with conical seats. It is also called a spring-

loaded seat when extensions are used.

– A

soft seat

is a screw application of e.g. metal on wood or

a screw application that uses lead washers or fibre wash-

ers as backing.

For a spring-loaded seat as well as for a soft seat, the max-

imum tightening torque is lower than for a hard seat. Also, a

clearly longer impact duration is required.

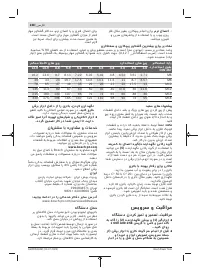

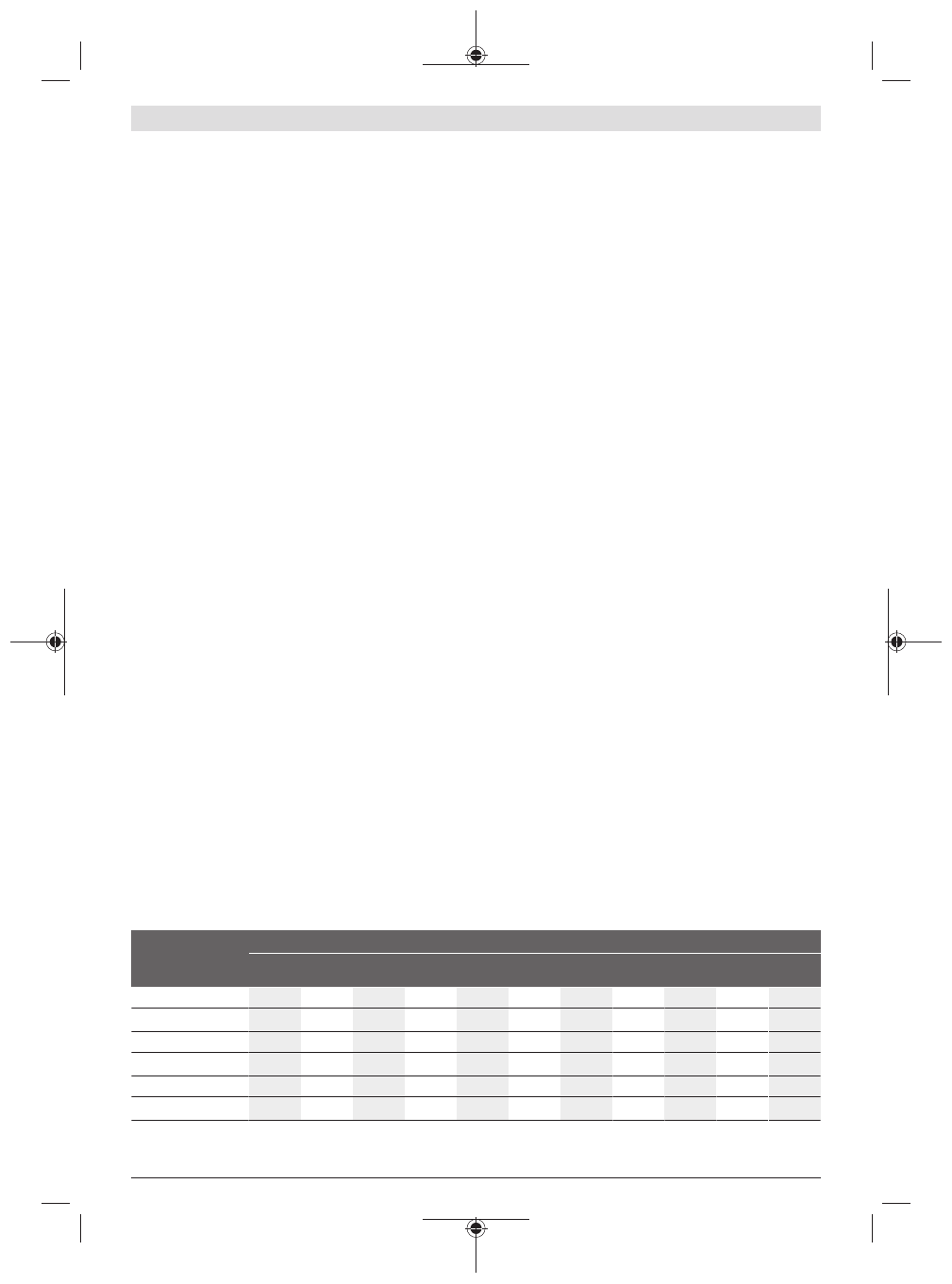

Guide values for maximum screw tightening torques

Figures given in Nm; calculated from the tensional cross-section; utilization of the yield point: 90% (with friction coefficient

µ

total

= 0.12). As a control measure, always check the tightening torque with a torque wrench.

Property Classes

according to

DIN 267

Standard Screws/Bolts

High-strength Bolts

3.6

4.6

5.6

4.8

6.6

5.8

6.8

6.9

8.8

10.9

12.9

M6

2.71

3.61

4.52

4.8

5.42

6.02

7.22

8.13

9.7

13.6

16.2

M8

6.57

8.7

11

11.6

13.1

14.6

17.5

19.7

23

33

39

M10

13

17.5

22

23

26

29

35

39

47

65

78

M12

22.6

30

37.6

40

45

50

60

67

80

113

135

M14

36

48

60

65

72

79

95

107

130

180

215

M16

55

73

92

98

110

122

147

165

196

275

330

Tips

Bosch Power Tools

160992A5UW | (14.07.2020)

Характеристики

Остались вопросы?Не нашли свой ответ в руководстве или возникли другие проблемы? Задайте свой вопрос в форме ниже с подробным описанием вашей ситуации, чтобы другие люди и специалисты смогли дать на него ответ. Если вы знаете как решить проблему другого человека, пожалуйста, подскажите ему :)